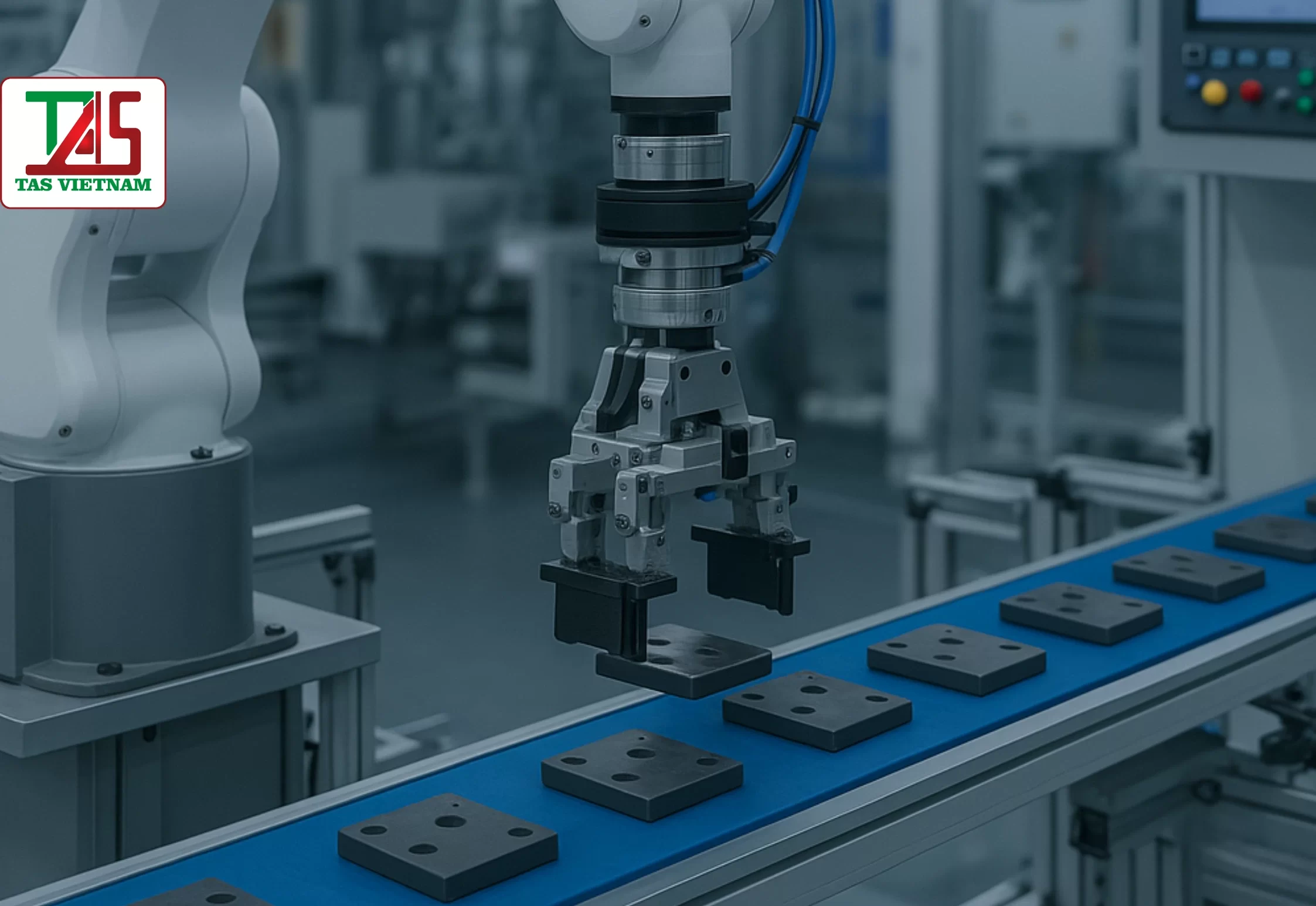

Smart Manufacturing Solution by TASVINA

Robotic Component Assembly

TASVINA implements robotic assembly systems equipped with grippers, sensors, and customized programming, capable of performing tasks such as welding, screwing, and component insertion.

Typical applications:

- Automotive: engine modules, electrical systems.

- Electronics: PCB assembly, chip placement, module integration.

- Consumer goods: home appliances, plastic parts.

Practical benefits:

- Stable production cycles with fewer interruptions.

- Reduced human error, especially in repetitive tasks.

- Flexible for different product types, though investment costs need to be assessed carefully.

Robotic Machining

For operations such as cutting, milling, grinding, and drilling, robots can complement or replace conventional CNC machines.

Key features:

- Flexible programming for various part types.

- Accuracy that meets most requirements in automotive and electronics; for ultra-precision parts, dedicated CNC equipment is still necessary.

- Shorter setup time, suitable for medium- to small-batch production with diverse parts.

Robotic Palletizing

In packaging and logistics, robotic palletizing helps reduce manual labor, especially for heavy or repetitive stacking tasks.

Applications:

- Food & beverage

- Packaging

- Warehousing and logistics

Practical advantages:

- Faster, more accurate stacking with minimal product damage.

- 24/7 operation for continuous workflows.

- Quick ROI (Return on Investment), often within 1–2 years.

Why Partner with TASVINA?

- End-to-end delivery: from consulting and design to installation and maintenance.

- Experienced engineering team, able to adapt systems to actual production needs.

- Balanced use of advanced technology, considering investment costs and scalability.

- Long-term support, with continuous system optimization instead of one-time installation.

Conclusion

Robotic automation does not always replace the entire workforce, but it is a proven solution to reduce long-term costs, improve productivity, and maintain quality.

TASVINA provides robotic services in assembly, machining, and palletizing, enabling businesses to implement automation step by step – from small-scale upgrades to large-scale production lines.

👉 Contact TASVINA to explore the most feasible robotic automation solution for your production needs.