In the era of Industry 4.0, Computer-Aided Manufacturing (CAM) has become an integral part of modern production systems. From automotive components to high-precision tooling, CAM software enables manufacturers to achieve faster, more accurate, and cost-effective results. However, as automation and digital technologies continue to advance, a key question arises:

Can CAM and automated quality management systems fully replace human inspection?

This discussion is particularly relevant for industries operating in Vietnam’s fast-growing manufacturing sector, where companies—both local and international—are seeking to balance efficiency, cost, and quality in a highly competitive environment.

1. The Role of CAM in Modern Manufacturing

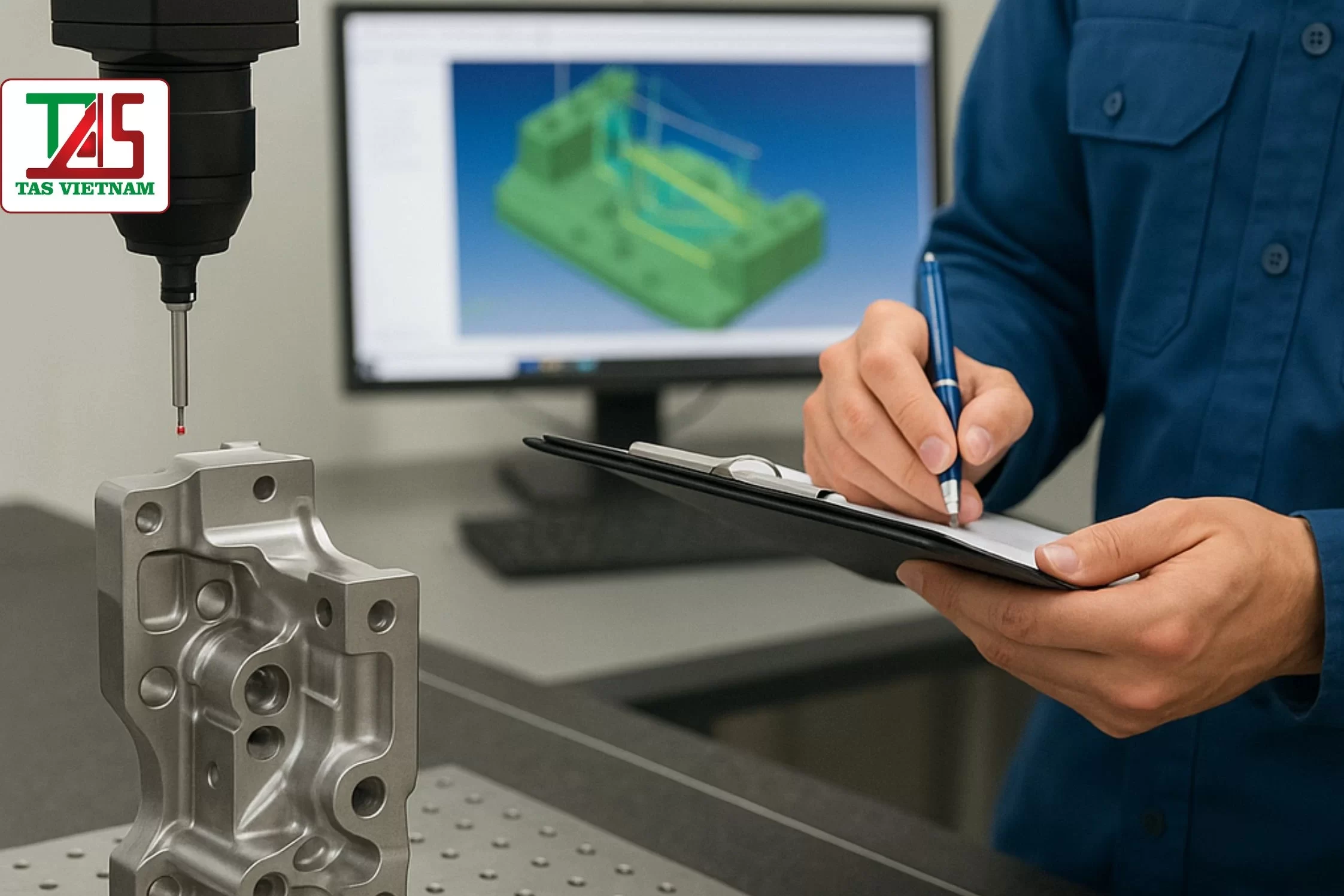

Computer-Aided Manufacturing (CAM) refers to the use of computer software and machinery to automate manufacturing processes. Integrated with Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE), CAM bridges the gap between digital product design and physical production.

Modern CAM systems such as Siemens NX, CATIA, or Autodesk Fusion 360 allow manufacturers to:

- Generate optimized toolpaths for CNC machines.

- Simulate machining operations before production.

- Reduce material waste and machining time.

- Integrate quality management and data feedback loops.

For companies like TASVINA, which specialize in design and simulation for the automotive and industrial sectors, CAM technology provides a foundation for precision, repeatability, and scalability.

2. Quality Management in the CAM Environment

In traditional manufacturing, quality control (QC) relies heavily on skilled inspectors who manually measure parts, review tolerances, and identify defects. While effective, this process is time-consuming and susceptible to human error.

CAM systems and digital quality management (DQM) tools have changed this landscape by introducing:

- In-process measurement: Using sensors and machine feedback to monitor quality during machining.

- Automated inspection reports: Real-time generation of dimensional and tolerance reports.

- Closed-loop control: Automatically adjusting tool paths or feeds based on feedback from inspection data.

- Integration with PLM and ERP systems: Ensuring quality data is shared across the entire production lifecycle.

This level of digital integration improves traceability, reduces rework, and enhances overall product quality.

3. The Benefits of Automation and Digital Inspection

Automated inspection—powered by CAM and advanced metrology tools—offers several key advantages:

- Speed and consistency: Machines can measure thousands of points per second with high repeatability.

- Reduced human bias: Automated systems apply objective criteria uniformly.

- Cost efficiency: Less time spent on manual inspection means higher throughput.

- Predictive analytics: Using data to anticipate defects before they occur.

For example, integrating Coordinate Measuring Machines (CMM) or laser scanning with CAM data enables full 3D validation of parts directly against the CAD model, providing unmatched accuracy.

4. The Limitations: Why Human Inspection Still Matters

Despite these advancements, human expertise remains irreplaceable in several areas:

- Interpretation and judgment: Machines can detect deviations, but human engineers understand why they occur and how to correct the root cause.

- Visual and aesthetic evaluation: Surface finish, color consistency, or subtle deformation often require human perception.

- Complex assemblies: When components interact dynamically—like in automotive systems—manual assessment ensures functional integrity.

- Continuous improvement culture: Experienced inspectors contribute feedback that refines design and process standards over time.

Automation can optimize processes, but quality assurance is not just about numbers—it’s about understanding context. Human inspectors ensure that products meet both technical specifications and real-world performance expectations.

5. A Hybrid Approach: The Future of Quality Management

The most effective strategy is not to replace human inspection, but to combine human intelligence with digital precision. This hybrid model leverages the strengths of both worlds:

- Automation handles routine and repetitive inspection tasks.

- Engineers focus on analysis, decision-making, and process optimization.

- AI and machine learning enhance defect prediction.

- Augmented reality (AR) and digital twins provide real-time visualization of quality data.

At TASVINA, this philosophy drives our engineering simulation and digital manufacturing solutions. By integrating CAM with advanced quality control systems, we help clients achieve data-driven manufacturing excellence—reducing downtime, ensuring traceability, and maintaining global quality standards.

6. Conclusion: Technology as an Enabler, Not a Replacement

CAM and digital quality management have transformed how industries operate. They deliver precision, speed, and repeatability at a level that was once impossible. Yet, complete replacement of human inspection remains unlikely—at least for now.

Humans and machines complement each other.

Machines excel at measurement and consistency; humans bring insight, intuition, and innovation.

For manufacturers in Vietnam and beyond, the goal should not be to eliminate human inspectors, but to empower them with smarter digital tools. As the manufacturing world moves toward Industry 5.0—where technology and human creativity coexist—companies that master this balance will lead the next wave of global innovation.