Introduction

In the era of Industry 4.0, precision and efficiency are the cornerstones of manufacturing success. Every second saved, every defect prevented, and every process optimized can make a measurable difference in cost and competitiveness. Among the many factors influencing production performance, jig and fixture design plays a crucial role — especially when smart technologies and digital tools come into play.

At TASVINA, we have seen how intelligent fixture design can transform production lines for automotive and industrial clients, helping them achieve consistent quality and productivity gains.

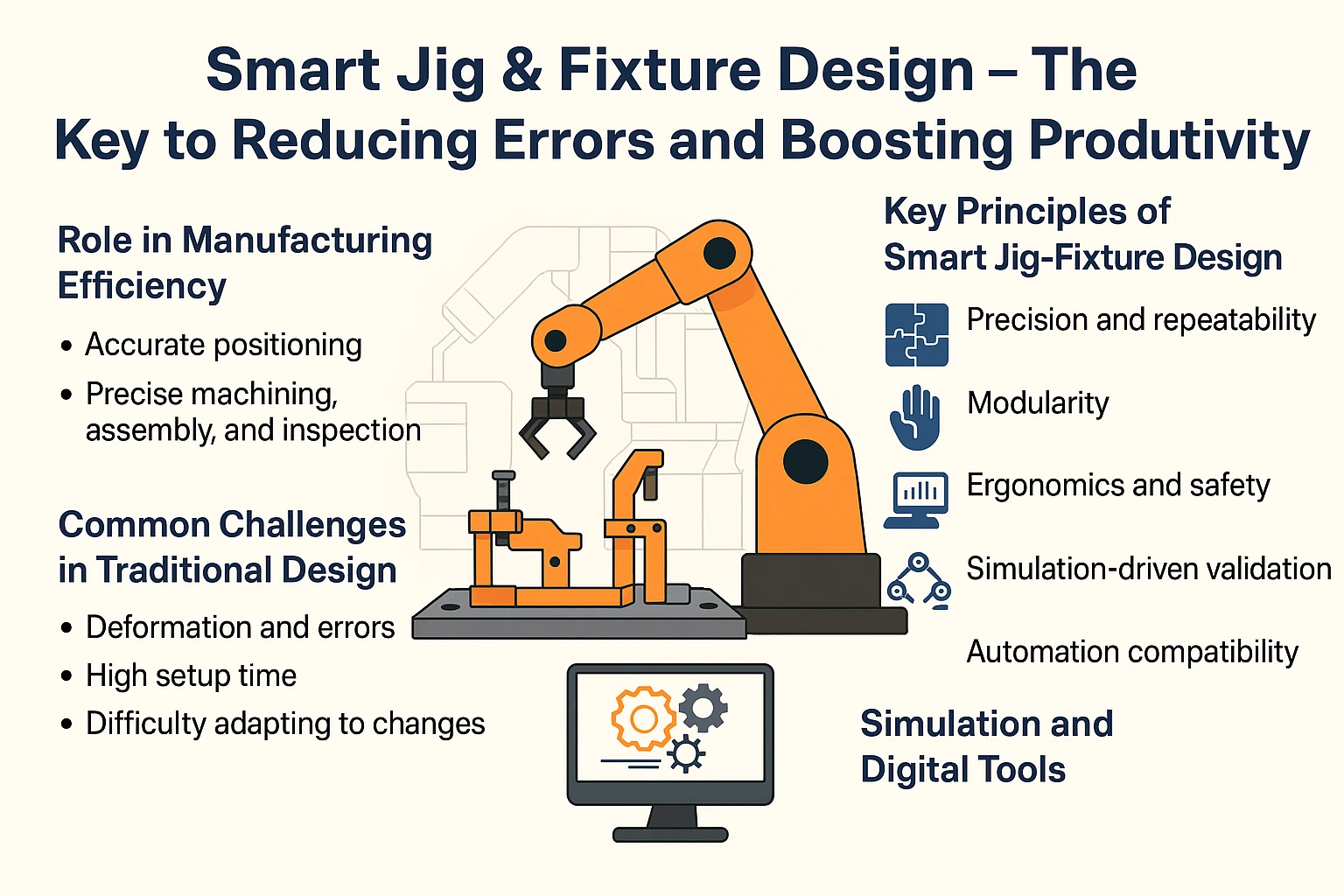

The Role of Smart Jig & Fixture Design in Manufacturing Efficiency

A well-designed jig or fixture ensures that each component is positioned accurately, enabling precise machining, assembly, and inspection. However, the true power of a smart fixture lies beyond physical stability — it involves data, simulation, and adaptability.

By integrating digital design and simulation tools, engineers can predict potential issues before production starts. Smart fixtures allow for faster changeovers, error-proofing (Poka-Yoke), and improved ergonomics for operators. This leads to lower rework rates and higher overall equipment effectiveness (OEE).

Common Challenges in Traditional Fixture Design

Traditional fixture design often relies heavily on experience and manual iterations. Without digital validation, even small design misalignments can lead to:

- Part deformation or dimensional errors.

- Excessive clamping force or insufficient stability.

- Increased setup time and operator fatigue.

- Difficulty adapting to product design changes.

Such inefficiencies not only increase costs but also limit production flexibility — a critical factor for manufacturers facing fast-changing market demands.

Key Principles of Smart Jig & Fixture Design

To create fixtures that meet today’s industrial needs, designers must adopt a data-driven and modular approach. The key principles include:

- Precision and Repeatability: Use tolerance analysis and digital twins to ensure consistent accuracy.

- Modularity: Design adaptable components that can be reused for different parts.

- Ergonomics and Safety: Prioritize operator comfort and easy accessibility during assembly.

- Simulation-Driven Validation: Apply CAE (Computer-Aided Engineering) to test clamping force, stress distribution, and deformation virtually.

- Automation Compatibility: Enable fixture integration with robots and automated lines.

These principles, when implemented effectively, form the foundation for smart manufacturing systems.

How Simulation and Digital Tools Improve Accuracy

Simulation is the bridge between design intent and real-world performance. At TASVINA, our engineers use advanced CAE tools such as finite element analysis (FEA) and motion simulation to validate fixture concepts early in the design stage.

This allows teams to identify weak points, optimize material selection, and fine-tune mechanical performance before any physical prototype is made. As a result, clients can reduce design revisions by up to 40% and accelerate the transition from concept to production.

TASVINA’s Approach: Smart Design Solutions for Automotive and Industrial Clients

With years of experience in automotive design, CAE simulation, and engineering outsourcing, TASVINA delivers high-precision fixture solutions tailored to each client’s production goals.

Our engineers combine mechanical expertise with digital simulation to ensure every jig and fixture meets three key goals:

- Accuracy in positioning and alignment.

- Reliability through robust structure and optimized clamping.

- Efficiency by reducing setup time and enhancing operator usability.

Through this integrated approach, we’ve supported manufacturers in Vietnam and abroad in achieving higher productivity, reduced defects, and smoother automation integration.

Conclusion

Smart jig and fixture design is no longer a luxury — it’s a necessity for companies seeking to stay competitive in modern manufacturing. By embracing digital design, simulation, and modular engineering, businesses can significantly improve production quality and throughput.

At TASVINA, we’re proud to partner with global manufacturers to bring innovation, precision, and efficiency to every stage of product development.

👉 Contact TASVINA today to explore how intelligent fixture design can transform your production process.

🌐 www.tasvina.com