1. Introduction

Die and mold design is the foundation of modern manufacturing, especially in automotive, electronics, and consumer goods industries. A precise mold design ensures production efficiency, cost reduction, and product durability.

However, even experienced engineers can make mistakes during the design process — leading to defective parts, higher machining costs, and production delays.

This article explores five common mistakes in mold design and how to prevent them effectively.

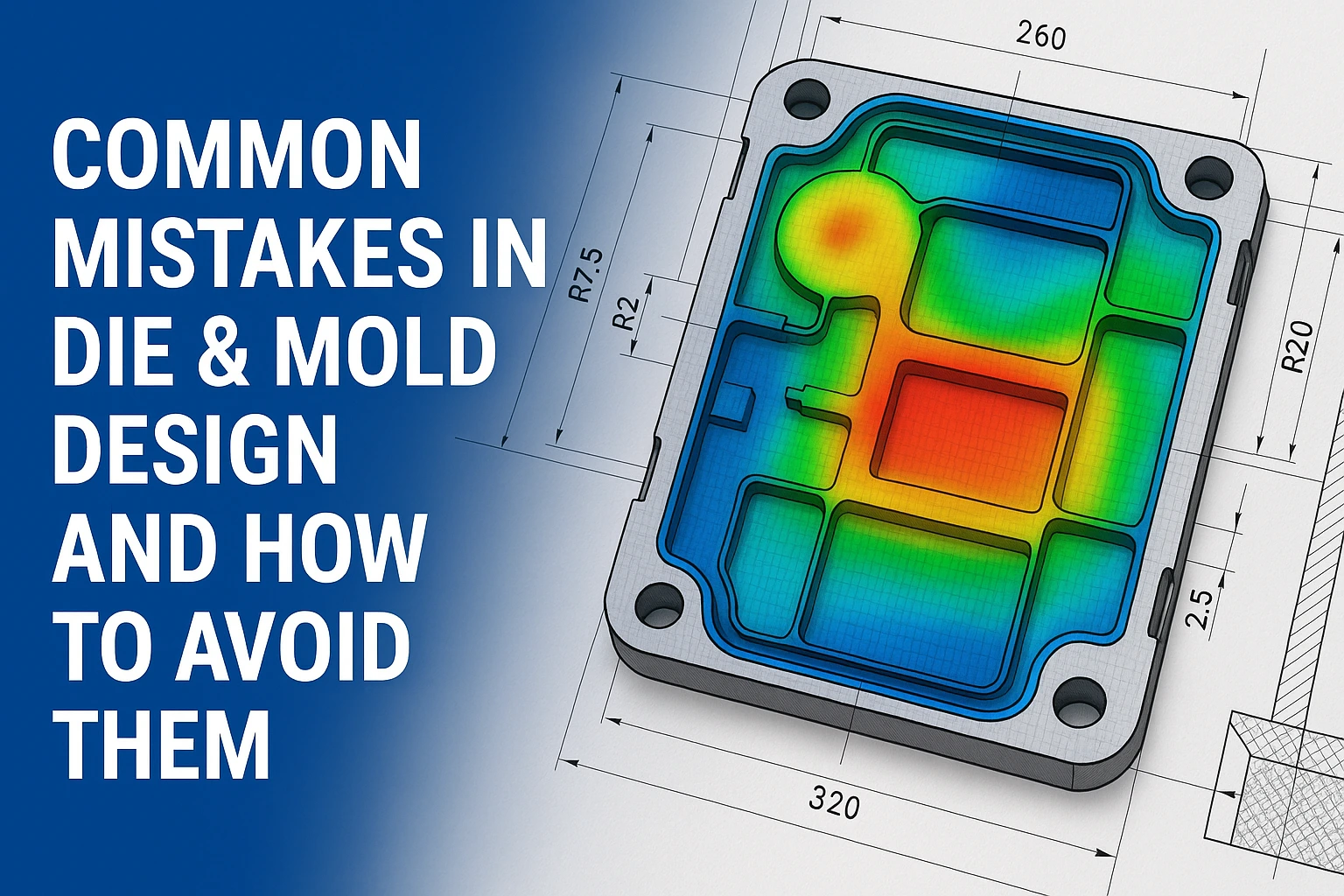

2. Mistake 1: Lack of Material Flow Analysis

One of the most common issues is skipping material flow simulation. Without analyzing how plastic or metal flows inside the mold, defects like air traps, shrinkage, or cracks may occur.

Solution: Use CAE software such as Moldflow, ANSYS, CATIA, or Simcenter to simulate flow and temperature distribution. This helps detect weak areas early and optimize gate positioning.

3. Mistake 2: Ignoring Manufacturability

A perfect CAD model may still be impractical to produce. Neglecting Design for Manufacturing (DFM) principles can result in overly complex molds, longer machining time, and higher costs.

Solution: Ensure early collaboration between design and production teams to balance functionality, aesthetics, and manufacturability.

4. Mistake 3: Lack of Standardization

Using unnecessary customized components can make maintenance and replacement complicated.

Solution: Adopt global standards such as HASCO, DME, and MISUMI. Standardization helps reduce cost, simplify assembly, and improve component compatibility.

5. Mistake 4: Inefficient Cooling System Design

Uneven cooling often leads to warpage, deformation, and longer cycle times.

Solution: Simulate the cooling and temperature distribution using CAE tools to optimize cooling channel layout. A balanced cooling system ensures stable temperatures and enhances mold lifespan.

6. Mistake 5: Insufficient Pre-production Validation

Skipping digital validation means costly errors will only surface during trial runs.

Solution: Perform 3D simulation, tolerance analysis, and virtual assembly checks before manufacturing. This minimizes risk and improves accuracy.

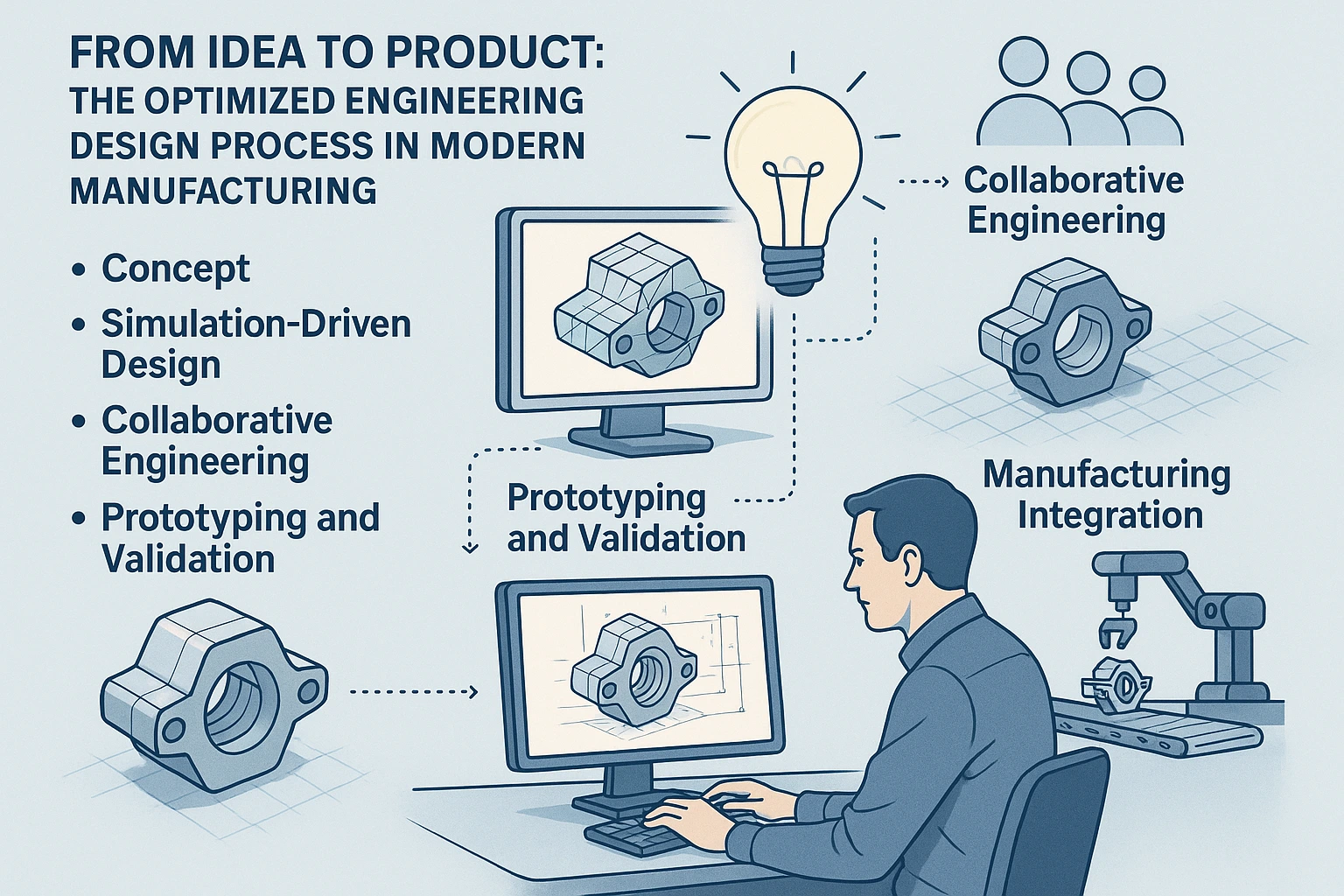

7. Modern Approach to Mold Design

Modern mold design combines engineering expertise with digital simulation.

An effective workflow should include:

- Full CAD–CAE–CAM integration.

- Use of AI and big-data simulation for early error prediction.

- Partnering with professional engineering firms like TASVINA to ensure quality and cost efficiency.

8. About TASVINA – Your Reliable Engineering Partner

TASVINA provides professional Design, CAE Simulation, and Automotive Engineering services in Vietnam.

With international-standard engineers, TASVINA has collaborated with global companies to develop high-precision molds and advanced product simulations.

We help optimize design processes, reduce manufacturing errors, and accelerate product launch.

👉 Contact TASVINA today to explore smart, cost-effective die & mold design solutions.

9. Conclusion

Avoiding these five common mistakes can save costs, enhance quality, and improve competitiveness.

With the right simulation tools and expert support, your mold design process can be faster, smarter, and more reliable — and TASVINA is ready to be your trusted partner in that journey.