1. Introduction

In today’s era of digital transformation, the Finite Element Method (FEM) has become a cornerstone of modern mechanical engineering. It enables engineers to simulate, analyze, and optimize complex systems before a single prototype is built. Whether in automotive design, aerospace, manufacturing, or electronics, FEM plays a vital role in improving performance, reducing costs, and accelerating innovation.

For international companies operating in Vietnam, understanding and applying FEM efficiently can be the key to building world-class products with local expertise. This article explores what FEM is, how it works, and why it has become an essential part of modern engineering.

2. What Is FEM?

The Finite Element Method is a numerical simulation technique used to approximate how structures and materials respond to physical forces such as stress, strain, heat, and vibration.

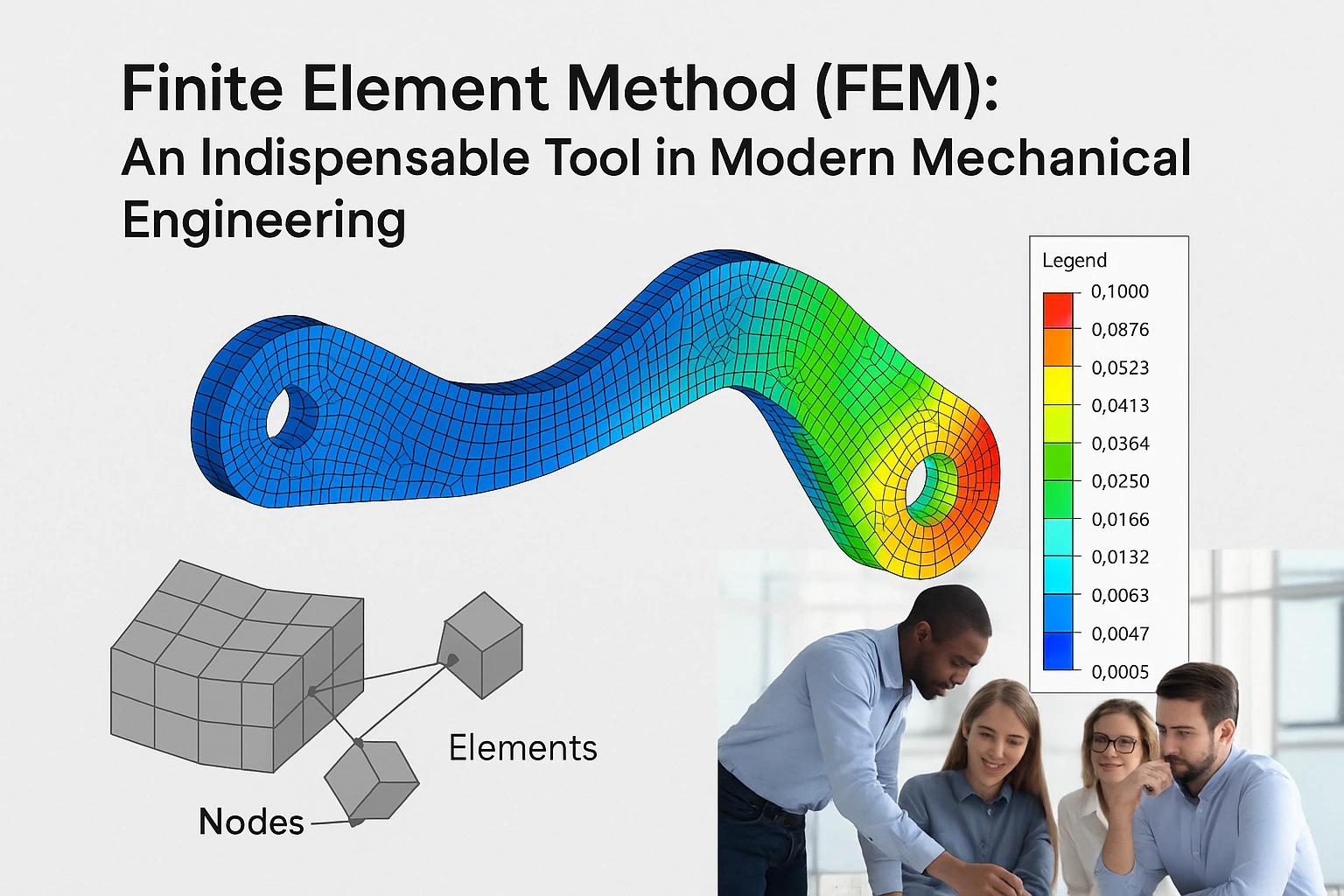

Instead of analyzing an entire object as a single complex system, FEM divides it into smaller, simpler elements – like small building blocks – which together represent the whole structure. Each element follows mathematical equations based on physical laws, and the computer solves them collectively to simulate real-world behavior.

This approach makes it possible to model anything from an aircraft wing to a microchip, allowing engineers to study its performance virtually and make data-driven design decisions.

3. How FEM Works

The FEM process typically involves several key stages:

- Geometry creation: The engineer builds a 3D model of the component or system to be analyzed.

- Meshing: The model is divided into thousands or even millions of small elements connected by nodes.

- Material definition: Mechanical, thermal, or other physical properties are assigned to each material.

- Boundary and load conditions: Real-world constraints, forces, pressures, or temperatures are applied.

- Computation and analysis: The FEM software (e.g., ANSYS, Abaqus, COMSOL, or Altair HyperWorks) solves the equations to determine displacements, stresses, and other responses.

- Post-processing: Results are visualized through color maps and contour plots, revealing where deformation, stress concentration, or heat buildup occurs.

This workflow provides engineers with a clear understanding of how their design will perform under realistic operating conditions—before any manufacturing begins.

4. Applications of FEM in Mechanical Engineering

FEM is used across nearly every industry that relies on mechanical systems. Some of its most common applications include:

- Structural analysis: Evaluating strength, stiffness, and fatigue life of mechanical parts, frames, and assemblies.

- Thermal analysis: Studying heat transfer and thermal stresses in engines, electronics, or energy systems.

- Dynamic and vibration analysis: Understanding how products respond to impacts, oscillations, and operational vibrations.

- Fluid-structure interaction: Combining FEM with computational fluid dynamics (CFD) to analyze pressure and flow effects.

- Optimization: Refining design geometry to achieve the best performance-to-weight or cost ratio.

By integrating these capabilities, FEM helps engineers ensure safety, efficiency, and reliability across all stages of product development.

5. Advantages of Using FEM

Adopting FEM offers a wide range of business and technical advantages:

- Reduced development cost and time: Virtual testing minimizes the need for expensive prototypes.

- Improved product quality: Simulation-based design identifies potential failures early.

- Enhanced innovation: Engineers can test multiple design scenarios quickly.

- Data-driven decision making: FEM provides quantifiable evidence for engineering choices.

- Sustainability: Reducing material waste and energy consumption during design optimization.

These benefits make FEM a strategic investment for companies aiming to enhance competitiveness in global markets.

6. FEM and Digital Engineering Transformation

As industries move toward Industry 4.0, FEM is a central part of the digital twin concept — a virtual replica of a physical product or process. Through integrated simulation and data analytics, engineers can predict performance, monitor operations, and continuously improve designs.

Combining FEM with AI-driven optimization and cloud-based simulation platforms allows global teams to collaborate in real time, accelerating innovation cycles and making high-level engineering accessible anywhere in the world.

7. Why FEM Is Especially Important in Vietnam’s Engineering Ecosystem

Vietnam is becoming a growing hub for manufacturing and engineering services, particularly for global automotive and industrial companies. The demand for high-precision simulation and CAE expertise is rapidly rising.

However, many foreign-invested firms face challenges in bridging local manufacturing with global engineering standards. That’s where experienced partners like TASVINA bring value—by delivering advanced FEM analysis with international quality and local cost advantages.

8. TASVINA – Your Reliable Partner in FEM and CAE Solutions

At TASVINA, we provide comprehensive engineering services specializing in Computer-Aided Engineering (CAE) and Finite Element Analysis (FEA). Our expertise covers a wide range of industries including automotive, electronics, energy, and industrial machinery.

Our key offerings include:

- Structural, thermal, and dynamic FEM analysis

- Product design optimization and simulation consulting

- Engineering support for R&D and manufacturing alignment

- Collaboration with international clients to ensure global quality standards

Our team of skilled engineers combines deep technical knowledge with creativity and precision. We are committed to delivering simulation-driven solutions that help our partners reduce cost, improve product performance, and accelerate development.

Our philosophy — “Engineering Better Solutions” — reflects our belief that innovation and practicality must go hand in hand.

9. Conclusion

The Finite Element Method is more than just a computational tool — it is a foundation for innovation, efficiency, and reliability in modern mechanical engineering. As industries continue to push the boundaries of performance, simulation-driven engineering will remain the key to smarter, faster, and more sustainable product development.

For companies seeking to implement advanced FEM or CAE solutions in Vietnam, TASVINA is your trusted partner — bringing international-level engineering expertise with local insight and commitment.

👉 Contact TASVINA today to discover how simulation can transform your product design process and drive engineering excellence.