1. Introduction

The rapid transition to electric mobility has made EV battery production one of the most strategically important manufacturing sectors worldwide. As global demand for electric vehicles continues to surge, manufacturers must scale production quickly while ensuring reliability, safety, and cost competitiveness. Automation—supported by robotics, advanced control systems, and intelligent digital workflows—has become the backbone of modern EV battery factories.

For engineering teams and foreign manufacturing companies operating in Vietnam, understanding how automation transforms EV battery production is critical for building resilient supply chains and maintaining global competitiveness. This article explores the key challenges, opportunities, and technological directions that are shaping automation in EV battery manufacturing today.

2. Why Automation Matters in EV Battery Production

EV battery manufacturing is highly complex, involving precise chemical processes, sensitive materials, and stringent safety requirements. Unlike traditional automotive assembly, battery production demands extremely tight tolerances, controlled environments, and continuous monitoring.

Automation unlocks essential advantages:

-

High precision and repeatability in electrode coating, stacking, welding, and assembly

-

Reduced risk of contamination in cleanroom environments

-

Improved safety when handling hazardous materials and thermal processes

-

Scalability to meet global EV demand

-

Lower long-term production cost through reduced manual labor and fewer defects

-

Accelerated time-to-market with stable, continuous production workflows

Because global EV leaders (Tesla, CATL, LG Energy Solution, Panasonic) rely heavily on automation, suppliers in Vietnam must also upgrade their automation capabilities to match international expectations.

3. Key Automation Stages in the EV Battery Manufacturing Flow

3.1 Electrode Manufacturing

Electrode production involves mixing slurry, coating, drying, and calendaring. Automation ensures:

-

Consistent slurry composition

-

Precise coating thickness

-

Stable drying temperatures

-

Real-time defect detection via vision systems

Automated electrode lines significantly reduce variation and improve energy density performance.

3.2 Cell Assembly (Winding/Stacking, Welding, Electrolyte Filling)

Cell assembly is the most automation-intensive stage due to high accuracy requirements:

-

Robotic stacking/winding maintains micron-level alignment

-

Laser welding robots ensure strong electrical connections

-

Automated electrolyte filling minimizes leakage risks

-

Advanced test stations verify internal resistance, leakage, and capacity

Modern Gigafactories operate these processes with fully automated lines to prevent contamination and ensure safety.

3.3 Formation and Aging

During formation, battery cells undergo controlled charge/discharge cycles. Automation enables:

-

Stable electrical input/output control

-

Predictive analysis of cell performance

-

Automated sorting of cells based on quality grading

This stage is critical for ensuring long battery life and safety.

3.4 Module and Pack Assembly

Automation plays a crucial role in high-volume module/pack production:

-

Robotic assembly and fastening

-

Automated thermal pad dispensing

-

Vision-guided adhesive application

-

Robotic pack sealing and leak testing

The combination of robots, AGVs/AMRs, and vision systems helps scale production while reducing risk of human error.

4. Major Challenges in EV Battery Automation

4.1 High Initial Investment

EV battery automation systems require significant capital expenditure:

-

High-precision robotics

-

Laser welding machines

-

Cleanroom systems

-

Advanced quality inspection technology

Small and medium manufacturers often face difficulty justifying this investment.

4.2 Complex Process Integration

EV battery lines combine mechanical, chemical, electrical, and thermal processes. Integrating them into a unified automated workflow requires:

-

Deep multidisciplinary engineering expertise

-

Customized control systems

-

Real-time data synchronization

-

Interoperability across equipment suppliers

Lack of skilled engineering resources is a major challenge for new factories.

4.3 Rapid Technology Evolution

Battery chemistries and designs (NMC, LFP, solid-state) change frequently, requiring automation systems to adapt quickly. Legacy equipment often cannot keep up with new cell formats or process requirements.

4.4 Quality and Safety Requirements

Errors in EV batteries may lead to severe consequences such as thermal runaway. Automation must meet:

-

ISO safety standards

-

Zero-defect production goals

-

High-resolution inspection and traceability

Ensuring this level of perfection is technically demanding.

4.5 Shortage of Skilled Engineers

Many factories in Vietnam lack experienced automation, robotics, and process engineers to design, implement, and maintain automated systems. This creates dependency on foreign integrators and slows down local automation adoption.

5. Opportunities: How Automation Creates Competitive Advantage

5.1 Enhancing Product Quality

Automation minimizes human variability and ensures consistent quality from electrode to pack assembly. With AI-powered inspection, manufacturers can detect micro-defects that humans cannot identify.

5.2 Scaling Production for Global Demand

The EV market is expected to grow exponentially through 2030. Automation enables high-volume manufacturing and faster line ramp-ups—key for companies entering global supply chains.

5.3 Lowering Production Costs

Although initial investment is high, automation reduces long-term costs by:

-

Decreasing labor requirements

-

Reducing waste and rework

-

Improving energy efficiency

-

Increasing equipment utilization rates

5.4 Strengthening Supply Chain Reliability

Automated systems support end-to-end traceability, enabling manufacturers to meet strict customer requirements from U.S., Japan, and EU clients.

5.5 Enabling Smart Factories

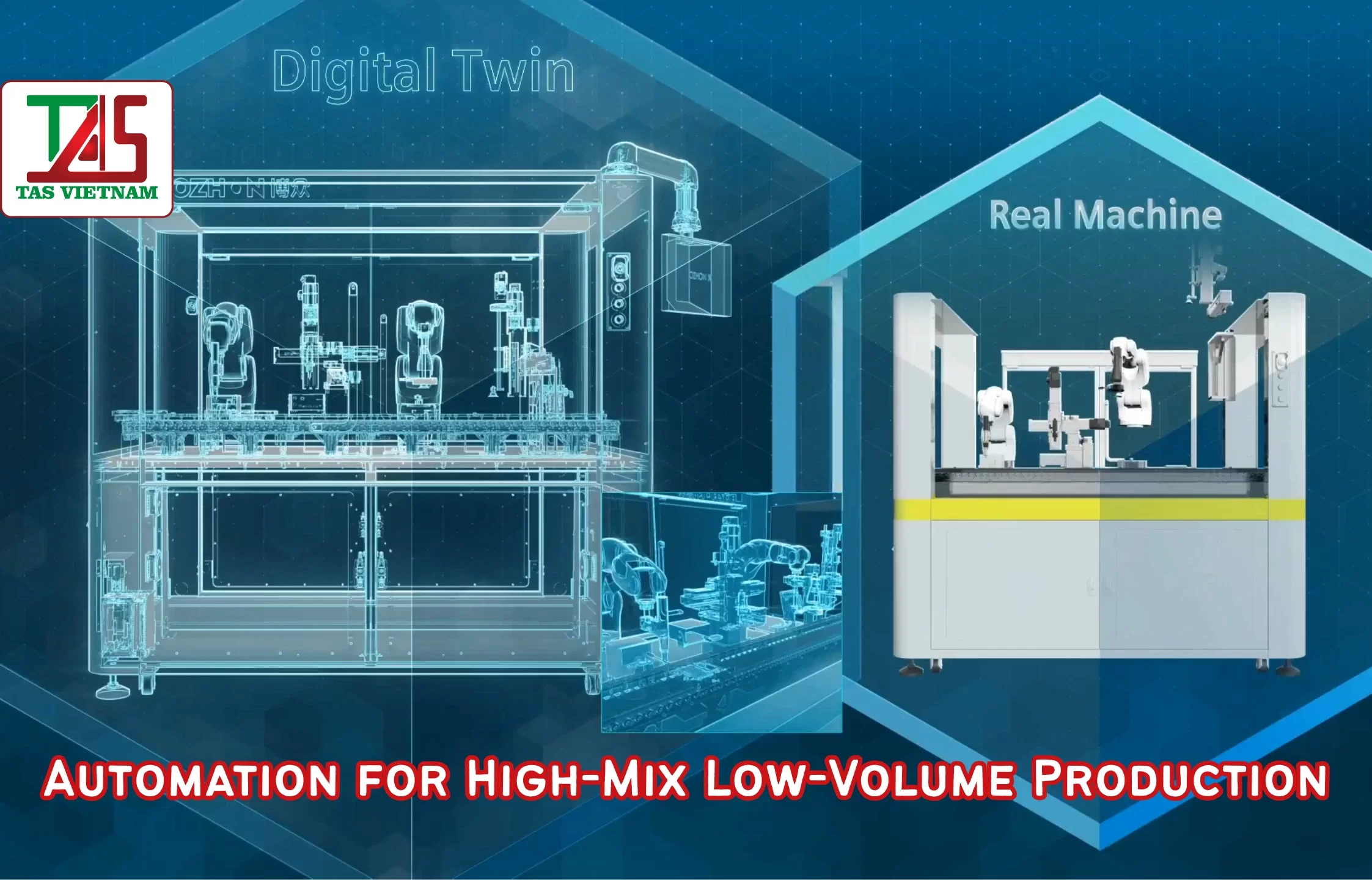

Automation combined with IoT, MES, and digital twins allows factories to:

-

Monitor real-time performance

-

Predict equipment failures

-

Optimize workflows based on data

-

Transition toward Industry 4.0 standards

Vietnamese factories that embrace smart automation gain a clear advantage over competitors.

6. The Role of Engineering Service Providers like TASVINA

Automation in EV battery manufacturing requires multidisciplinary expertise in mechanical design, controls engineering, simulation, production optimization, and robotics integration. Service providers such as TASVINA play a critical role in helping international companies in Vietnam:

-

Design automation solutions tailored to EV battery lines

-

Provide CAD/CAE engineering support

-

Develop digital twins for process optimization

-

Support equipment integration, testing, and commissioning

-

Deliver ongoing technical support for operations

With experienced engineers, strong technical capability, and proven outsourcing experience, TASVINA helps companies enhance efficiency, reduce risk, and achieve global-standard manufacturing quality.

7. Conclusion

As the EV industry continues accelerating, automation becomes indispensable for achieving scale, reliability, and cost competitiveness in battery manufacturing. Despite challenges—high investment, complex integration, rapid technology changes—opportunities for automation are far greater. Companies that adopt automation early will lead the next phase of global EV innovation.

For foreign manufacturers operating in Vietnam, partnering with capable engineering service providers like TASVINA can significantly accelerate automation deployment and ensure long-term competitiveness in the rapidly expanding EV battery market.