Introduction

In today’s global manufacturing landscape, high-mix, low-volume (HMLV) production has become increasingly common—especially in industries such as electronics, automotive components, consumer goods, and precision engineering. Unlike mass-production systems, HMLV environments deal with frequent product changes, smaller batch sizes, and highly diversified customer demands. As foreign companies expand operations in Vietnam and seek optimized manufacturing performance, the need for adaptable, flexible, and intelligent automation solutions becomes stronger than ever.

This article explores how automation technologies—robotics, smart vision systems, data-driven control, and digitalization—can transform HMLV production lines. It also analyzes the challenges, implementation strategies, and benefits, providing engineering-level insights for decision-makers contemplating automation investments in Vietnam.

1. Understanding High-Mix, Low-Volume Production

HMLV refers to manufacturing environments where:

-

Many different product types or variants are produced

-

Each product runs in small or variable batch sizes

-

Changeovers occur frequently

-

Product lifecycles may be short or customized

-

Operators often manage multiple tasks simultaneously

Traditional automation is typically designed for predictable, large-volume production. In contrast, HMLV environments require high adaptability, reconfigurability, and responsiveness. This is where modern automation technologies come into play.

2. Key Challenges of Automating HMLV Production

2.1 Frequent Product Changeovers

In HMLV operations, switching between product types can occur daily—or even every few hours. Manual changeovers lead to:

-

Downtime

-

Process variation

-

Human-dependent outcomes

-

Extended training requirements

Automation must accommodate rapid, reliable, low-effort changeovers.

2.2 High Process Variability

Different products may require:

-

Different tooling

-

Unique inspection criteria

-

Adjustable motion paths

-

Multi-step workflows

Robots, machines, and systems must respond to these variations without extensive reprogramming.

2.3 Small Batch Sizes

Traditional industrial automation is not cost-effective for low-volume runs. Solutions must be:

-

Modular

-

Scalable

-

Quick to set up

-

Cost-optimized

2.4 Workforce Gaps

In Vietnam, manufacturers face:

-

Shortages of skilled operators

-

Rising labor costs

-

High demand for quality and consistency from international clients

Automation is increasingly necessary to maintain global standards.

3. Automation Technologies Enabling HMLV Adaptability

3.1 Collaborative Robots (Cobots)

Cobots are ideal for HMLV lines because they are:

-

Easy to program

-

Flexible in task handling

-

Safe to work alongside humans

-

Quick to redeploy

-

Affordable compared to traditional robotics

Applications such as pick-and-place, machine tending, screwdriving, and small-scale assembly benefit greatly.

3.2 Vision-Guided Robotics

Vision systems provide:

-

Automated part detection

-

Orientation adjustment

-

On-the-fly path correction

-

Automatic switching between product types

AI-based vision enables robots to handle mixed product bins and unpredictable orientations.

3.3 Modular and Reconfigurable Automation

This includes:

-

Modular conveyors

-

Quick-change tooling

-

Universal robot grippers

-

Plug-and-play control units

Such systems allow rapid line reconfiguration without engineering downtime.

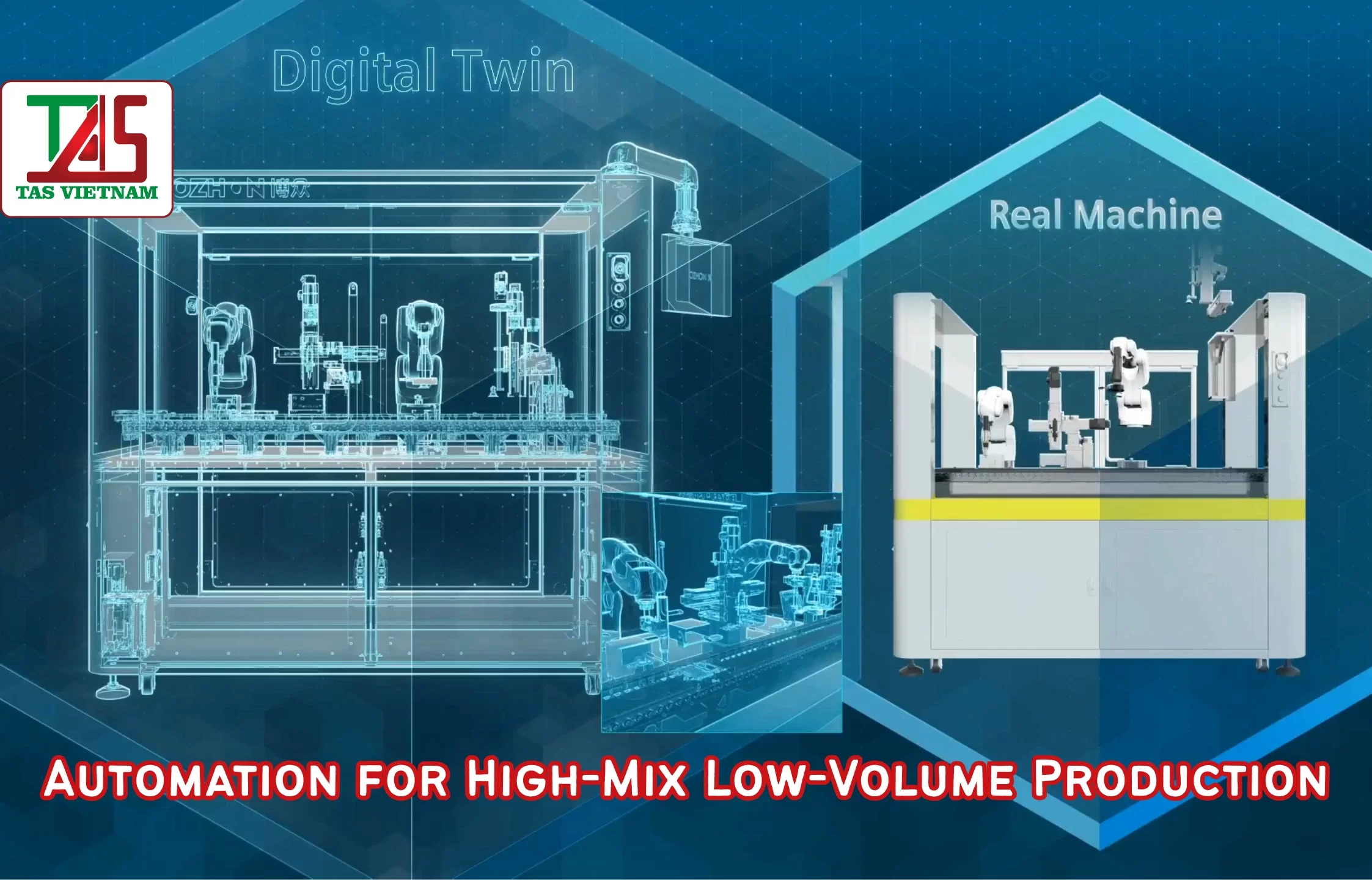

3.4 Digital Twins & Simulation (CAD/CAE-Based Integration)

Using digital twins, engineering teams can:

-

Simulate workflows before installation

-

Optimize layouts

-

Predict performance

-

Adjust automation logic virtually

This shortens deployment time and reduces risk in HMLV factories.

3.5 Smart Data & IoT Integration

Real-time monitoring helps manufacturers:

-

Track performance across product variants

-

Predict machine failures

-

Manage changeovers intelligently

-

Optimize cycle times

Data-driven automation increases reliability in complex production conditions.

4. How Adaptable Automation Adds Value to HMLV Operations

4.1 Reduced Downtime

Rapid changeover technology cuts downtime dramatically. Automatic parameter switching and universal tooling allow faster transitions with fewer errors.

4.2 Enhanced Quality & Consistency

Automation minimizes variation across multiple product types. Vision inspection ensures every unit meets specifications—critical for global customers requiring strict quality compliance.

4.3 Better Workforce Utilization

Operators can shift from repetitive tasks to higher-value responsibilities such as supervision, troubleshooting, and process optimization.

4.4 Increased Responsiveness to Customer Requirements

With automation, manufacturers can:

-

Accept more custom orders

-

Adjust production schedules faster

-

Handle diversified product portfolios

This improves competitiveness in Vietnam’s growing manufacturing ecosystem.

4.5 Cost Optimization

Although initial investment may seem high, automation delivers long-term gains:

-

Lower labor dependency

-

Higher OEE

-

Reduced waste

-

Longer equipment lifetime

For HMLV environments, adaptable automation provides strong ROI.

5. Best Practices for Implementing Automation in HMLV Manufacturing

5.1 Map All Product Variants and Workflows

A thorough engineering analysis of CAD models, process steps, and quality requirements ensures automation systems handle every possible scenario.

5.2 Start with High-Impact Use Cases

Examples include:

-

Machine loading/unloading

-

Packaging

-

Inspection

-

Repetitive assembly tasks

These deliver fast, measurable improvements.

5.3 Design for Reconfigurability

Systems should be modular, portable, and scalable to accommodate future product changes.

5.4 Use Standardized Interfaces

Universal grippers, standardized robot programming, and plug-and-play modules accelerate deployment.

5.5 Train Local Teams

Automation succeeds when operators and engineers fully understand the system. Training reduces support dependence and improves uptime.

6. Why Vietnam Manufacturers Should Prioritize Adaptable Automation

As Vietnam becomes a key manufacturing hub for global supply chains, customers expect international-level productivity and consistency. Adaptable automation supports:

-

Faster lead times

-

Higher reliability

-

Stable quality despite product diversity

-

Compliance with overseas clients’ standards

Foreign companies operating in Vietnam can benefit significantly from automation partners capable of delivering engineering-level customization and multidisciplinary expertise.

Conclusion

High-mix, low-volume production is complex—but automation technologies have evolved to meet these challenges. Adaptable, intelligent, and modular automation solutions allow manufacturers to improve efficiency, quality, and flexibility without sacrificing cost-effectiveness.

For companies producing diverse product portfolios in Vietnam, investing in automation is not just an upgrade—it’s a strategic necessity. With the right design, integration, and engineering support, automation can turn HMLV operations into a competitive advantage, enabling businesses to scale, innovate, and meet global expectations.