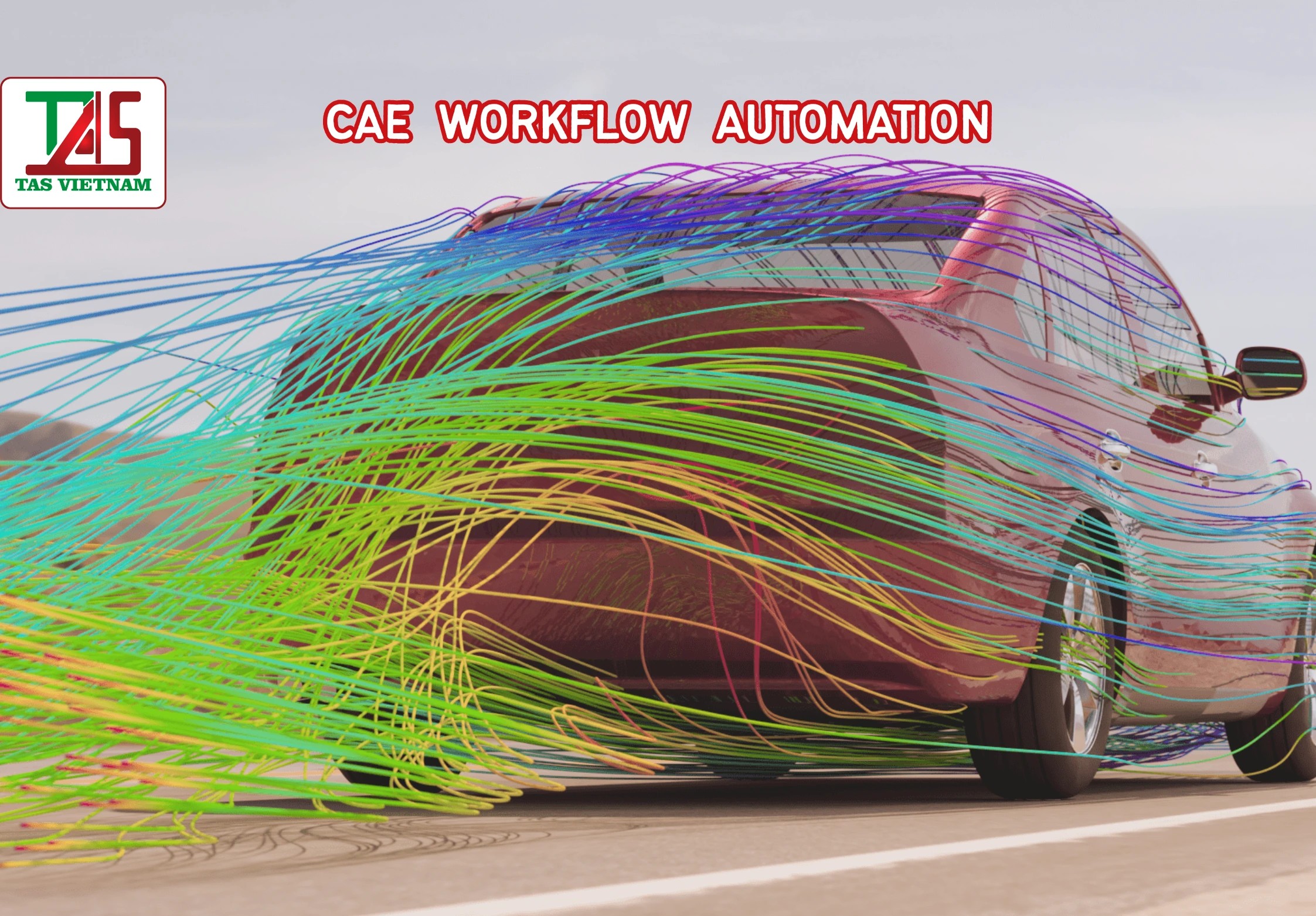

In today’s engineering landscape, the pressure to deliver innovative, high-quality products in shorter timeframes has never been greater. Global companies operating in Vietnam—especially in automotive, manufacturing, aerospace, and consumer electronics—are facing increasing demand for faster verification, higher design accuracy, and reduced development costs.

Computer-Aided Engineering (CAE) plays a central role in this transformation. Yet despite its power, traditional CAE workflows are often slow, highly manual, and dependent on expert engineers performing repetitive tasks. The question many organizations now ask is:

How can we evolve from failure-prone manual workflows to a streamlined, automated CAE process that accelerates development and improves product performance?

This article explores how CAE automation transforms the entire engineering lifecycle—reducing iterations, increasing reliability, and enabling companies to go from failure to perfection.

1. The Limitations of Manual CAE Workflows

Traditional CAE processes typically involve a series of time-consuming and human-dependent steps:

-

Model preparation (geometry cleanup, defeaturing)

-

Meshing

-

Boundary condition setup

-

Solver configuration

-

Post-processing and reporting

-

Iteration loops based on design changes

While these tasks are essential, they introduce several challenges:

1.1 High Risk of Human Error

Manual repetition of tasks increases the probability of inconsistencies—mesh quality variations, setup mistakes, missing constraints, or incorrect material data. These errors may lead to failed simulations and unreliable results.

1.2 Long Iteration Cycles

Each design change requires CAE engineers to redo several steps from scratch, significantly slowing down the R&D cycle. As a result, companies delay their validation phases and struggle to meet customer timelines.

1.3 Dependence on Senior Experts

Many CAE tasks require deep domain expertise. When organizations rely heavily on a small group of specialists, scalability becomes a critical bottleneck.

1.4 Difficulty Maintaining Standards Across Teams

Manual methods make it challenging to enforce modeling guidelines, naming conventions, meshing standards, and reporting formats across multi-disciplinary or multi-location teams.

These issues accumulate into costly delays, unpredictable workloads, and greater development risks.

2. CAE Automation: A Strategic Shift in Engineering Operations

CAE automation introduces a structured, repeatable, and scalable approach to simulation activities.

Instead of relying on manual repetition, companies can employ:

-

Automated geometry cleanup and mesh generation scripts

-

Parameterized templates for loading, materials, and solver settings

-

API-driven simulation setups

-

Automatic post-processing and report generation

-

Workflow orchestration tools that connect CAD → CAE → PLM

This shift delivers immediate and long-term benefits across engineering, production, and business operations.

2.1 Faster Product Development Cycles

Automated workflows minimize manual steps, enabling simulation engineers to complete in minutes what previously required hours. This speed directly shortens validation loops and accelerates decision-making.

2.2 Improved Consistency and Accuracy

By enforcing standardized processes, companies significantly reduce human error. Mesh quality, solver settings, and loads become consistent across projects, allowing more reliable comparison of design iterations.

2.3 Higher Productivity and Engineer Satisfaction

Automation reduces repetitive work, allowing CAE experts to focus on innovation, deep analysis, and design improvement—not on clicking through thousands of manual operations.

2.4 Scalability Across Teams and Global Locations

With automated templates and scripts, multinational companies can ensure all teams—from Japan to Vietnam—adhere to the same engineering standards and best practices.

2.5 Data-Driven Decision Making

Automated post-processing enables real-time comparison of performance metrics, making it easier for teams to quickly identify which design direction yields the best results.

3. The Role of CAE Automation in Failure Reduction

Failures—whether physical prototype failures, simulation crashes, or validation inconsistencies—are costly. Automation directly helps prevent common types of engineering failures:

3.1 Eliminating Errors in Pre-Processing

Automation can:

-

Detect invalid geometries

-

Apply standardized mesh settings

-

Auto-generate load cases

These steps avoid crashes during solving and ensure high-quality models.

3.2 Ensuring Repeatable Solver Conditions

Automated solvers remove setup variability. Identical loading, materials, and constraints improve simulation fidelity and reduce failed runs.

3.3 Intelligent Monitoring of Simulation Health

Workflow systems can detect divergence, unstable calculations, or unrealistic deformations early—saving compute time and project resources.

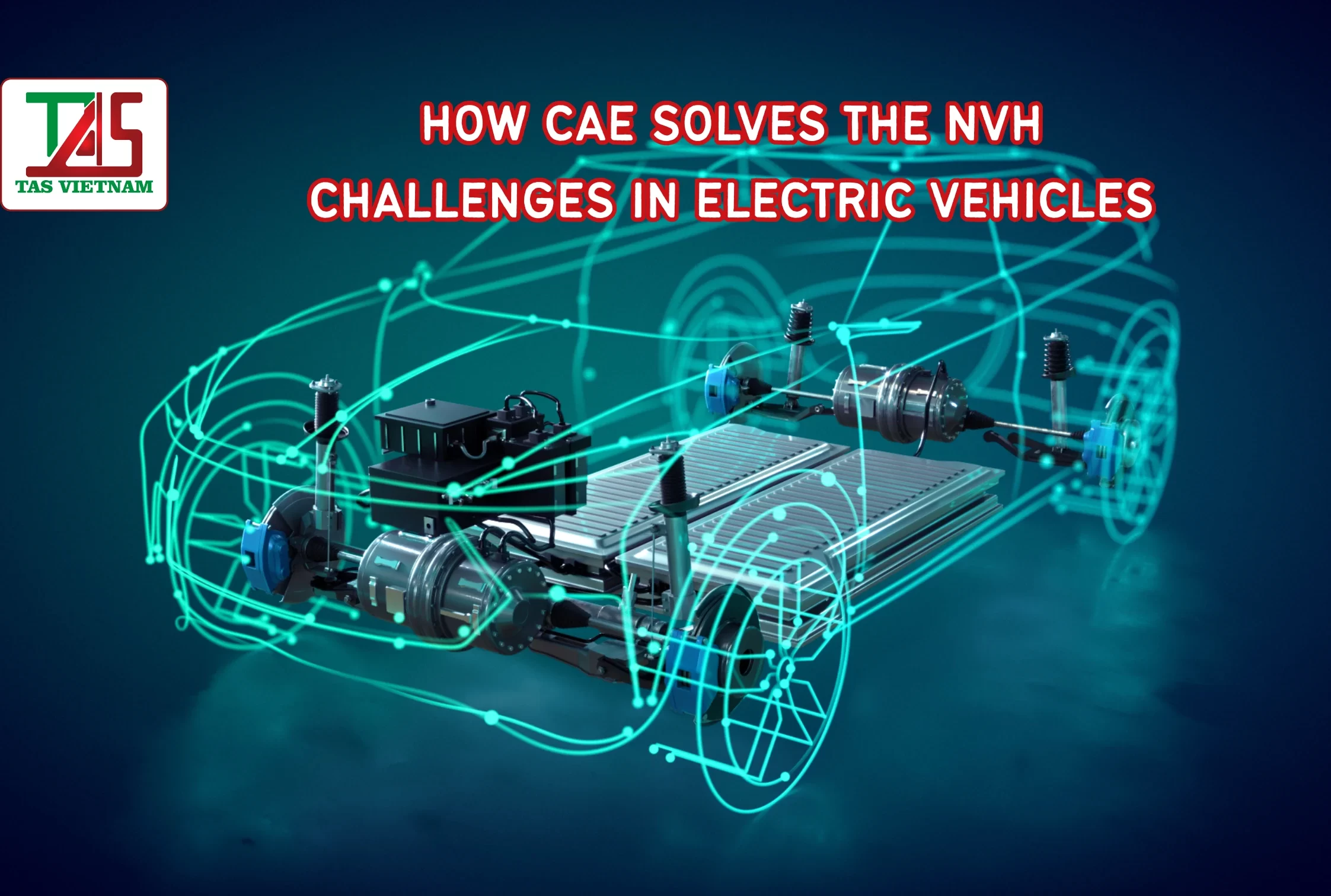

3.4 Strengthening Design Validation

Automated post-processing provides consistent KPIs such as stress distribution, fatigue cycles, NVH metrics, crash deformation patterns, or thermal flow characteristics.

Organizations that embrace automation dramatically reduce the number of unexpected failures in late-stage development.

4. Transforming the Product Development Cycle

CAE automation is not merely a technical upgrade—it is a transformation of the entire engineering ecosystem.

4.1 From Sequential to Concurrent Engineering

Traditionally, engineering teams wait for simulation results before proceeding. Automation enables near real-time feedback, helping multiple departments collaborate simultaneously and shorten the overall timeline.

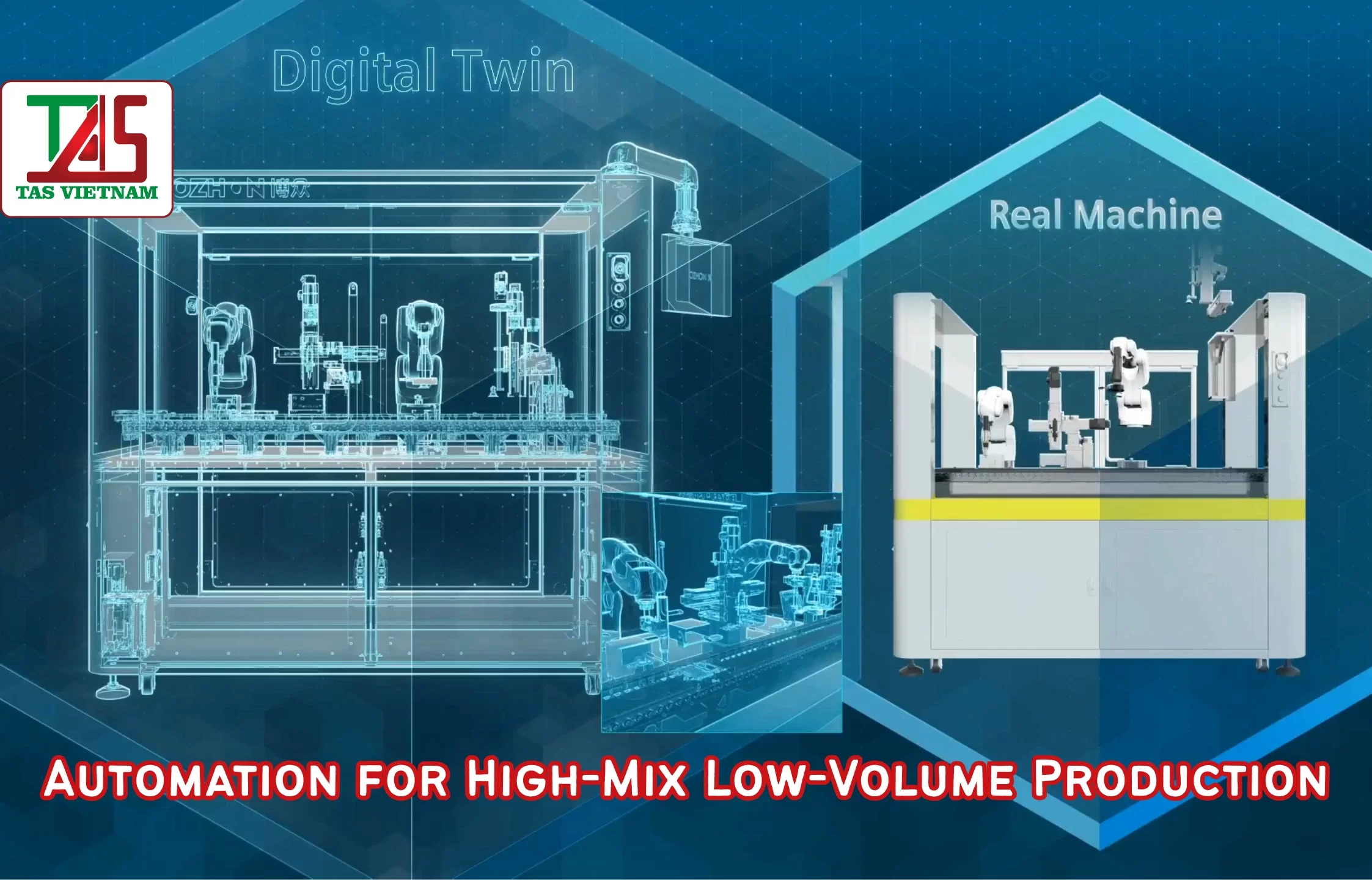

4.2 Supporting Digital Twins and Virtual Prototyping

Automation allows organizations to integrate simulation throughout the lifecycle, enabling:

-

Real-time digital twin updates

-

Large design space exploration

-

Optimization-driven development

Companies reduce physical prototypes and make earlier, more informed decisions.

4.3 Enabling AI-Driven Design Optimization

Modern CAE automation frameworks work seamlessly with artificial intelligence. Machine learning can evaluate thousands of variants—something impossible manually.

4.4 Lowering Total Development Costs

Although automation requires initial investment, the return is significant:

-

Fewer prototypes

-

Reduced engineer workload

-

Shorter project durations

-

Faster time-to-market

This direct cost-saving benefit makes automation a competitive necessity.

5. Why Many Global Companies Choose Vietnam for CAE Automation Support

Vietnam has become a key hub for engineering outsourcing—particularly CAE, CAD, CAM, and automation engineering. Companies expanding into the Asia-Pacific region choose Vietnam for several strategic reasons:

-

Highly skilled engineering workforce

-

Strong English and Japanese communication capabilities

-

Competitive production and R&D costs

-

Flexible collaboration models (onsite, offshore, hybrid)

-

Experience with global OEM and Tier-1 engineering standards

Engineering service providers like TASVINA support international clients with end-to-end CAE solutions:

-

Workflow automation

-

Simulation template development

-

Multiphysics CAE analysis

-

CAD/CAE integration

-

Data standardization

-

Reporting automation

-

Design optimization

This allows foreign companies in Vietnam to accelerate development cycles while maintaining world-class quality standards.

6. Conclusion: Moving from Failure Toward Perfection

Automation is transforming the CAE landscape. Organizations that still rely on manual modeling, meshing, and post-processing risk falling behind in innovation, time-to-market, and product performance.

By automating CAE workflows, companies unlock:

-

Faster design iterations

-

Higher simulation accuracy

-

Reduced failures

-

Lower development costs

-

Empowered engineering teams

The future of engineering is defined by speed, intelligence, and automation. Companies that adopt these innovations today will lead the market tomorrow—from early concepts to perfect final products.