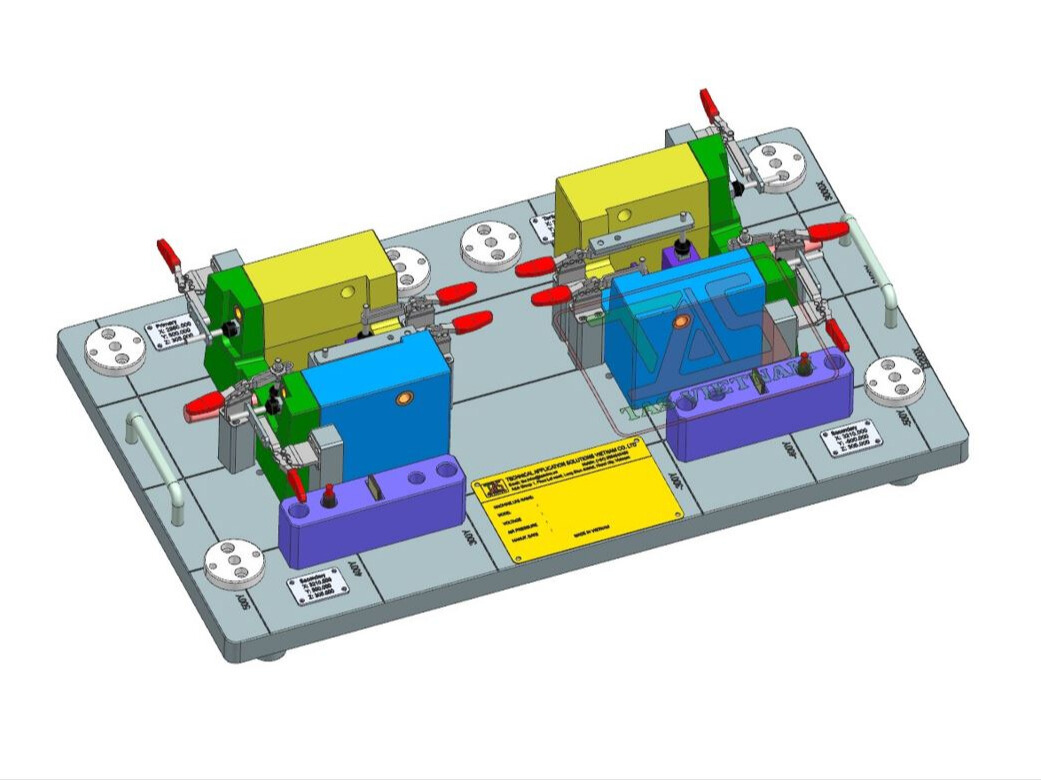

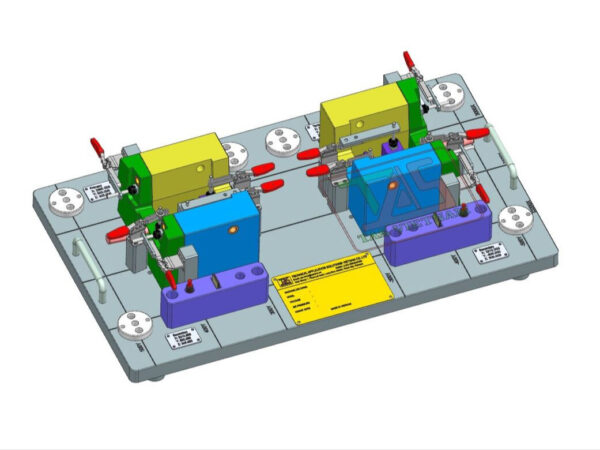

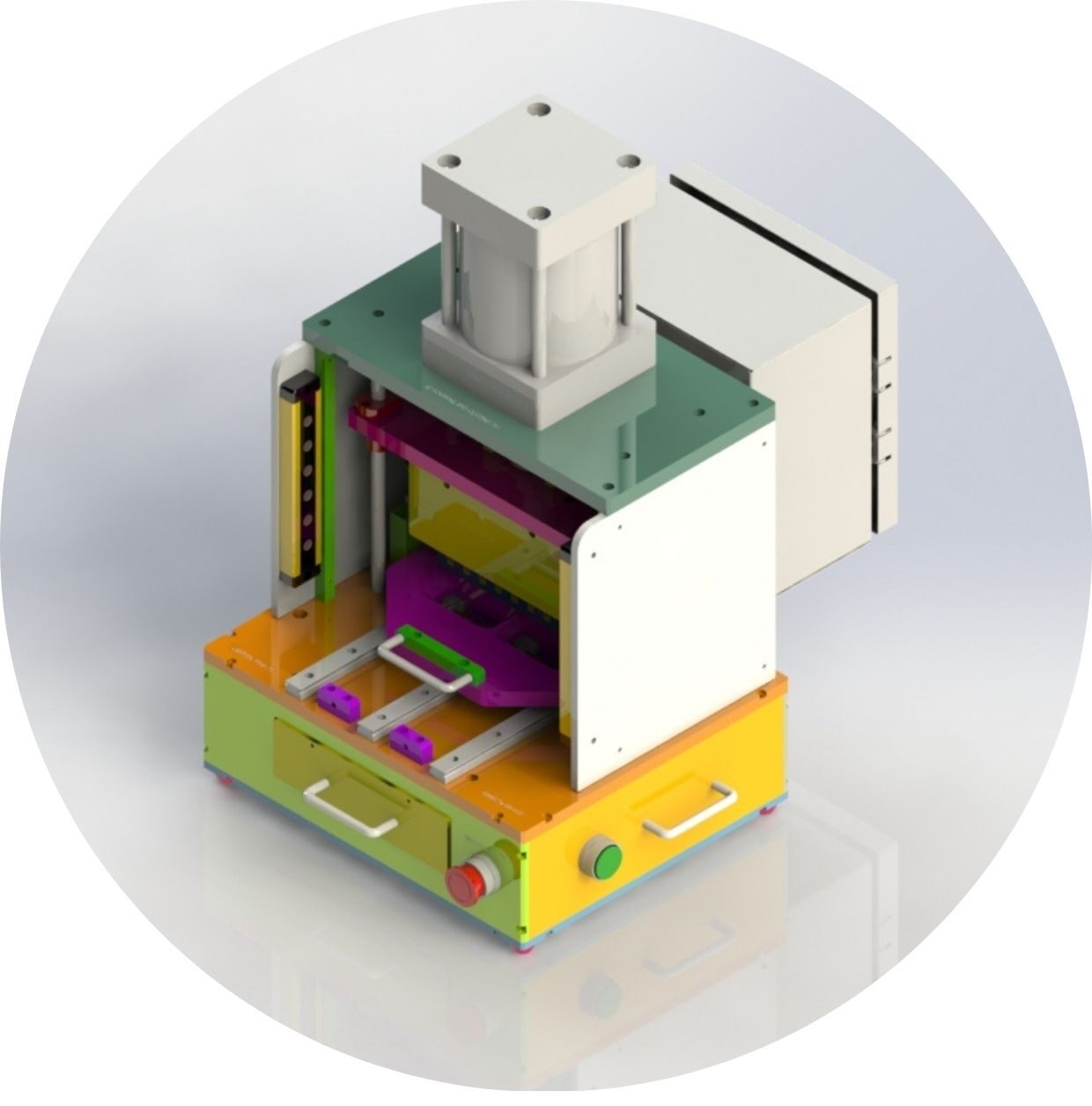

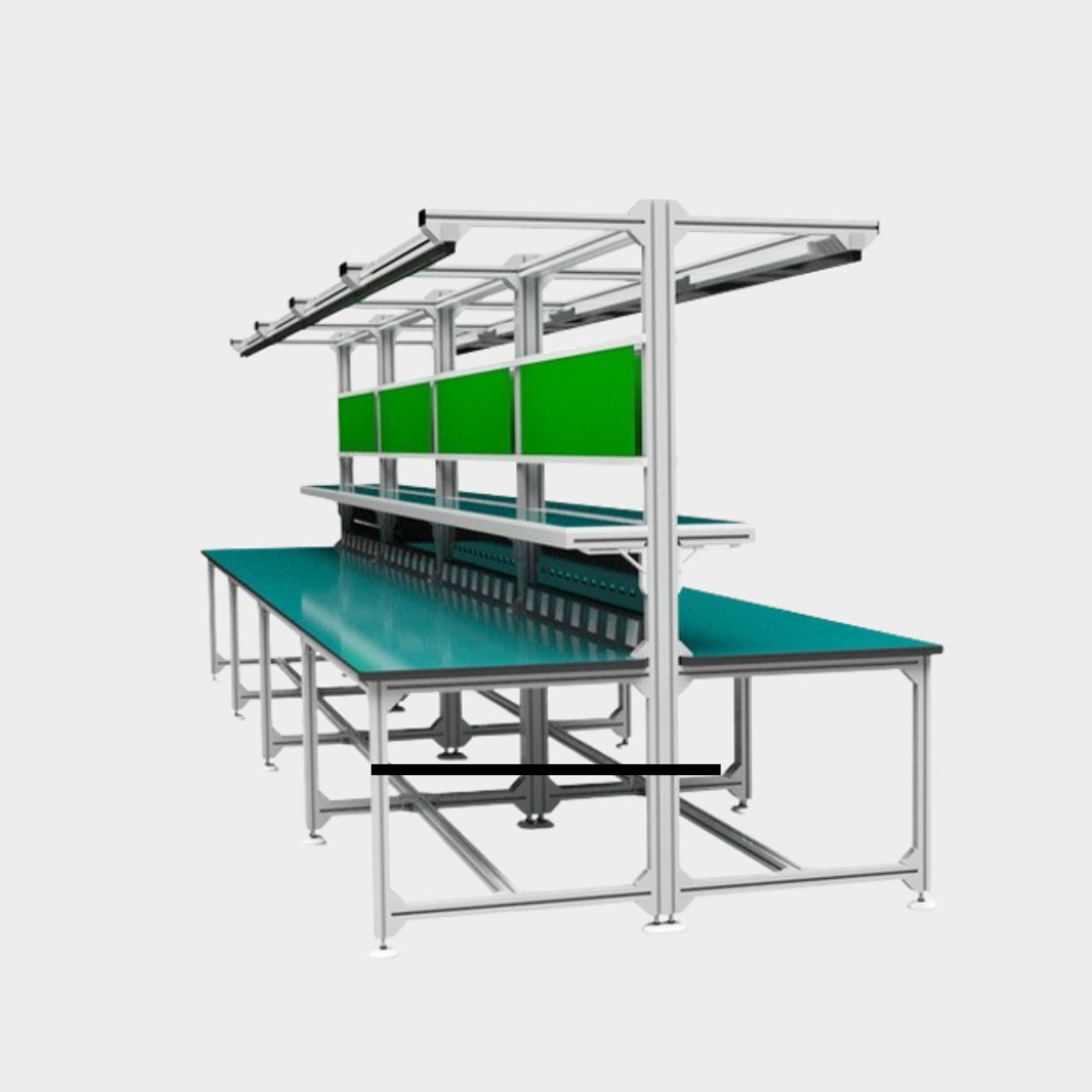

Description

A checking fixture/ inspection JIG is a type of JIG used to inspect and measure the technical specifications of a product after assembly or processing. Inspection JIGs help determine whether the product meets the established quality and technical standards. This tool is essential in quality control processes, ensuring the accuracy, consistency, and reliability of products before they are used or shipped.

Roles of Checking fixture/ Inspection JIGs:

- Ensures quality: Inspects the accuracy of technical specifications, helping to ensure that the product meets quality standards.

- Saves inspection time: With a specialized design, inspection JIGs allow for quick and easy inspection processes.

- Reduces human error: By securing and positioning the product, inspection JIGs minimize errors caused by manual handling.

- Increases inspection efficiency: Enables high-speed inspection of multiple products in succession, suitable for mass production.

Common Types of Inspection JIGs:

- Dimensional inspection JIG: Measures specific dimensions of a product, such as length, width, diameter, or thickness.

- Shape inspection JIG: Ensures the product has the correct shape according to the design, such as angles, radii, or curvature.

- Position inspection JIG for holes or details: Checks the positions of drilled holes, mounting holes, or other details to ensure assembly accuracy.

- Functional inspection JIG: Tests the functionality or performance of the product (e.g., valve seal integrity, weld strength, etc.).

Inspection JIGs are widely used in various industries such as electronics, automotive, mechanical engineering, and consumer goods manufacturing, helping to ensure that the final product meets quality standards before reaching the customer.

Contact: Nguyen Xuan Canh (Mr. Orion) (Sales Manager) - Phone: (+84) 905.648.436 - Email: tas.info@tasvina.com

Reviews

There are no reviews yet.