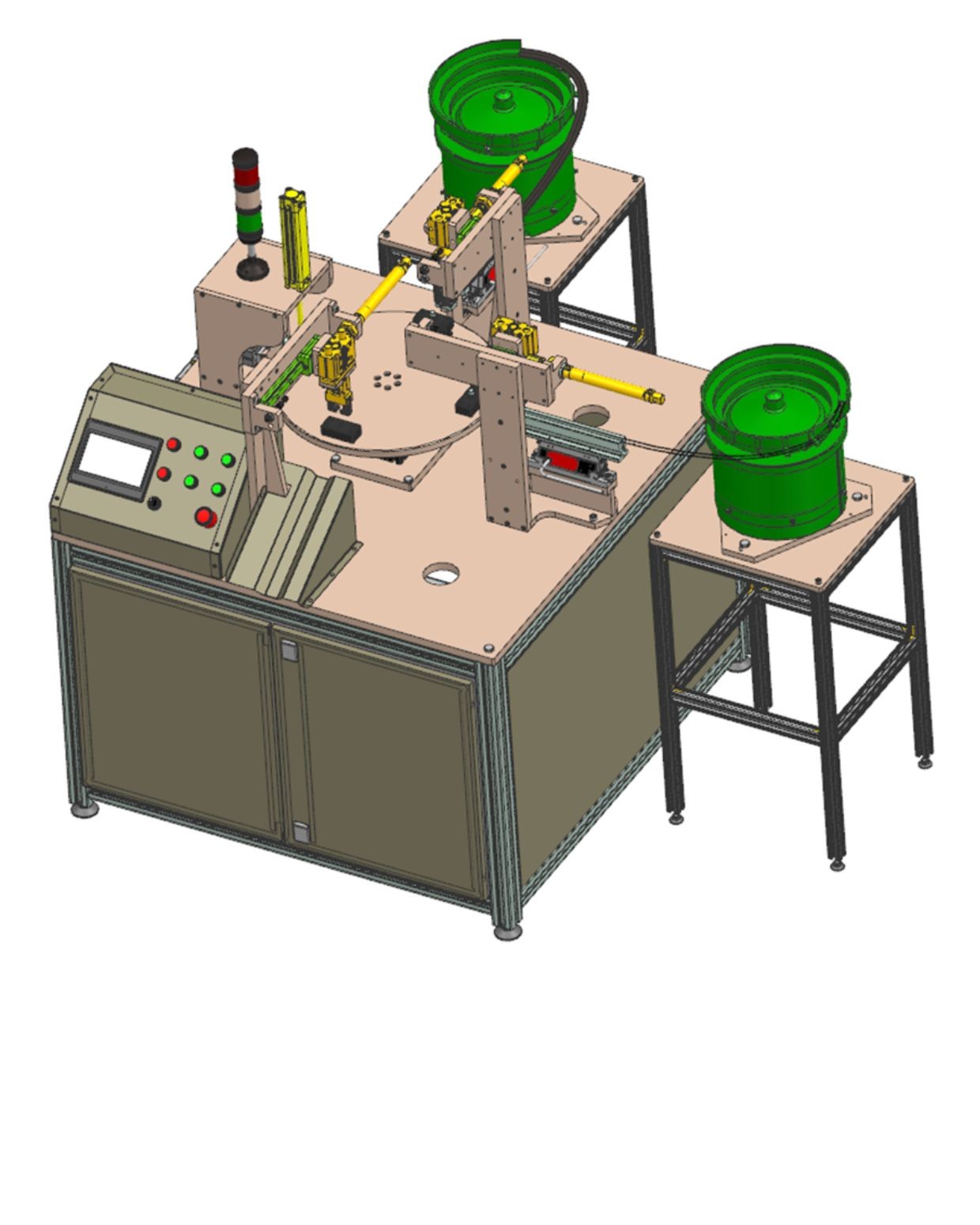

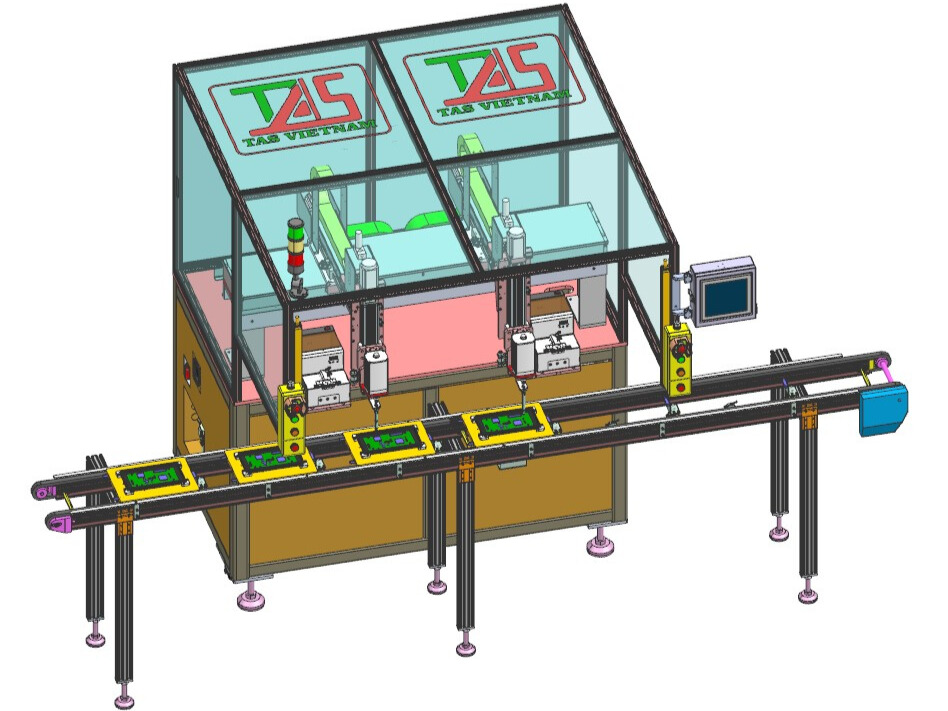

Description

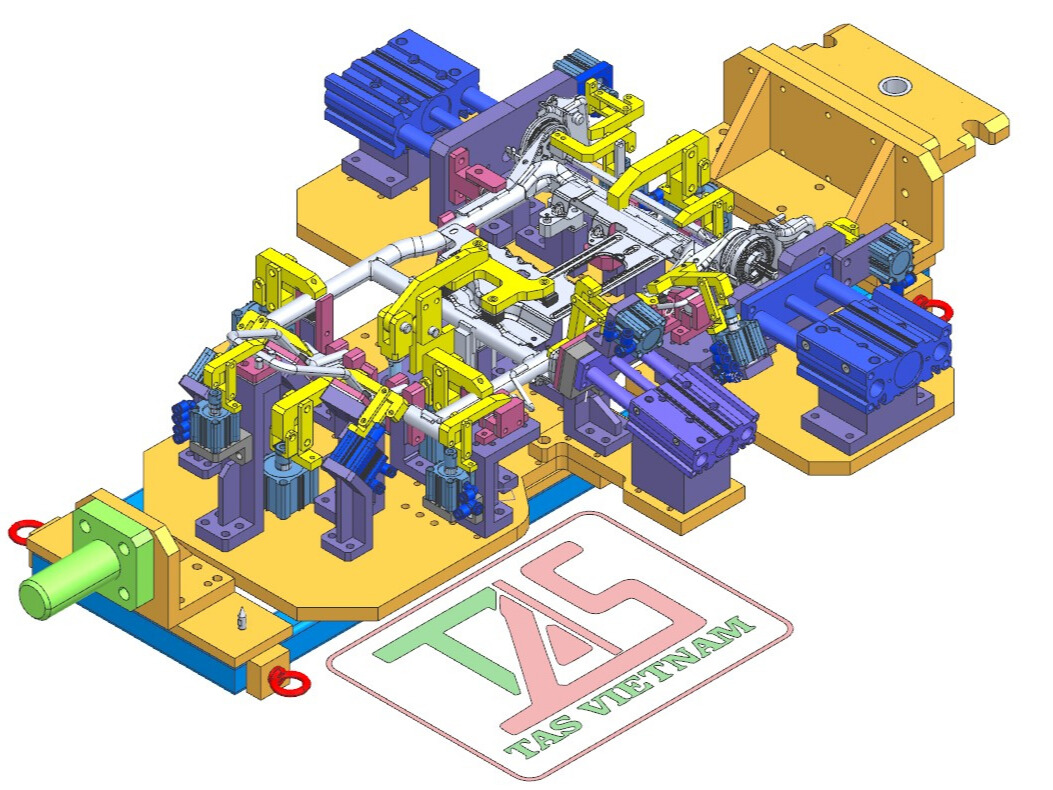

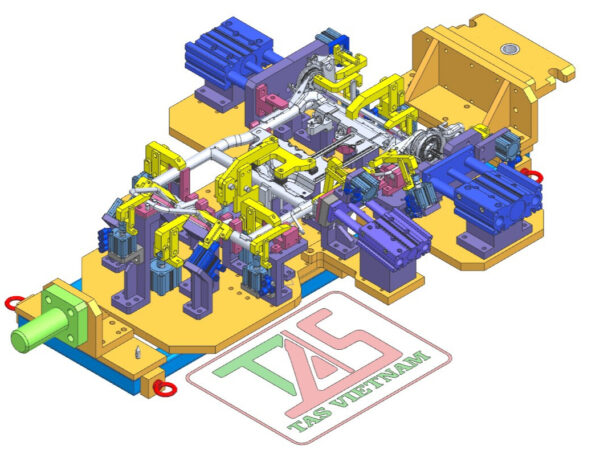

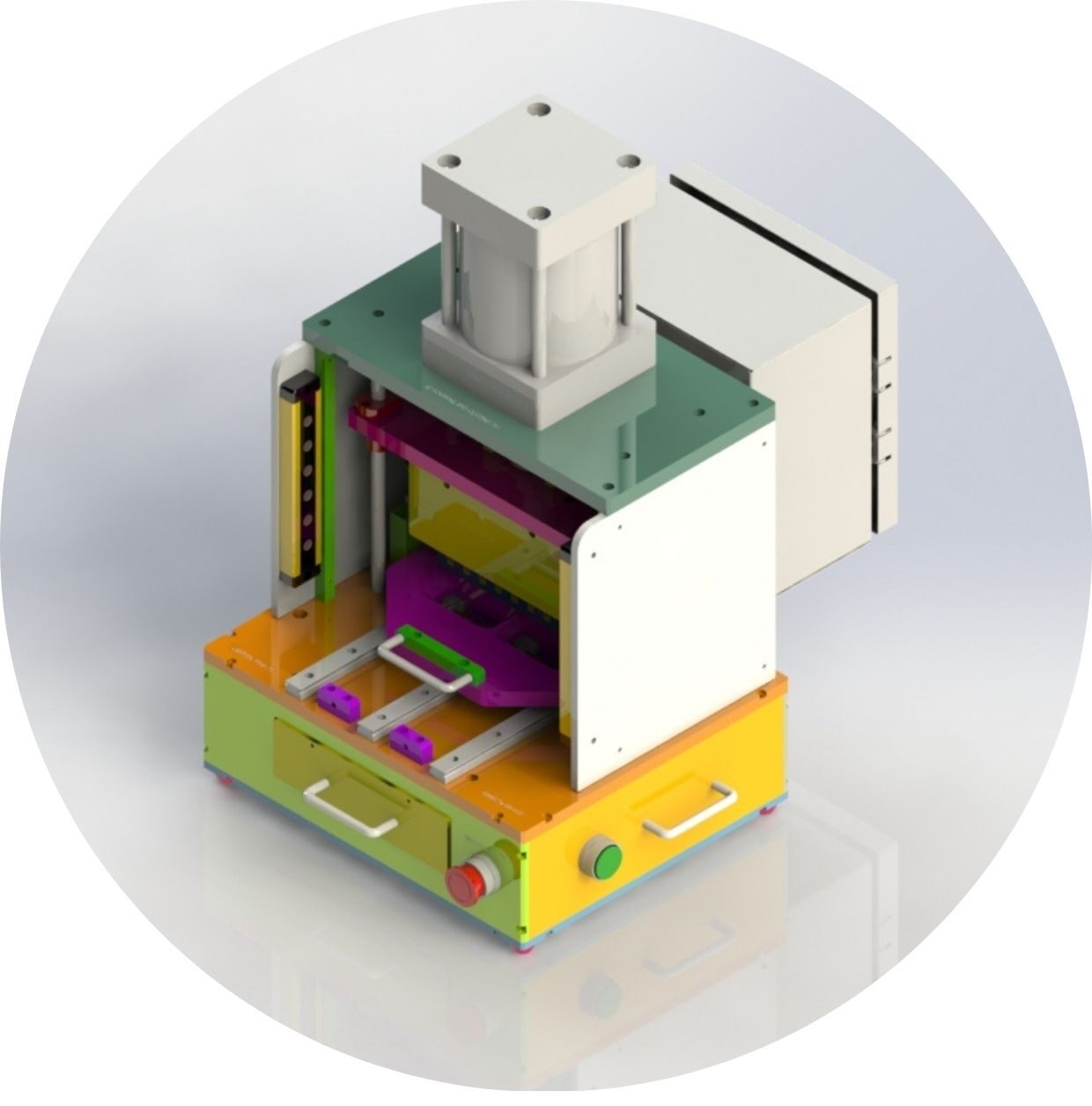

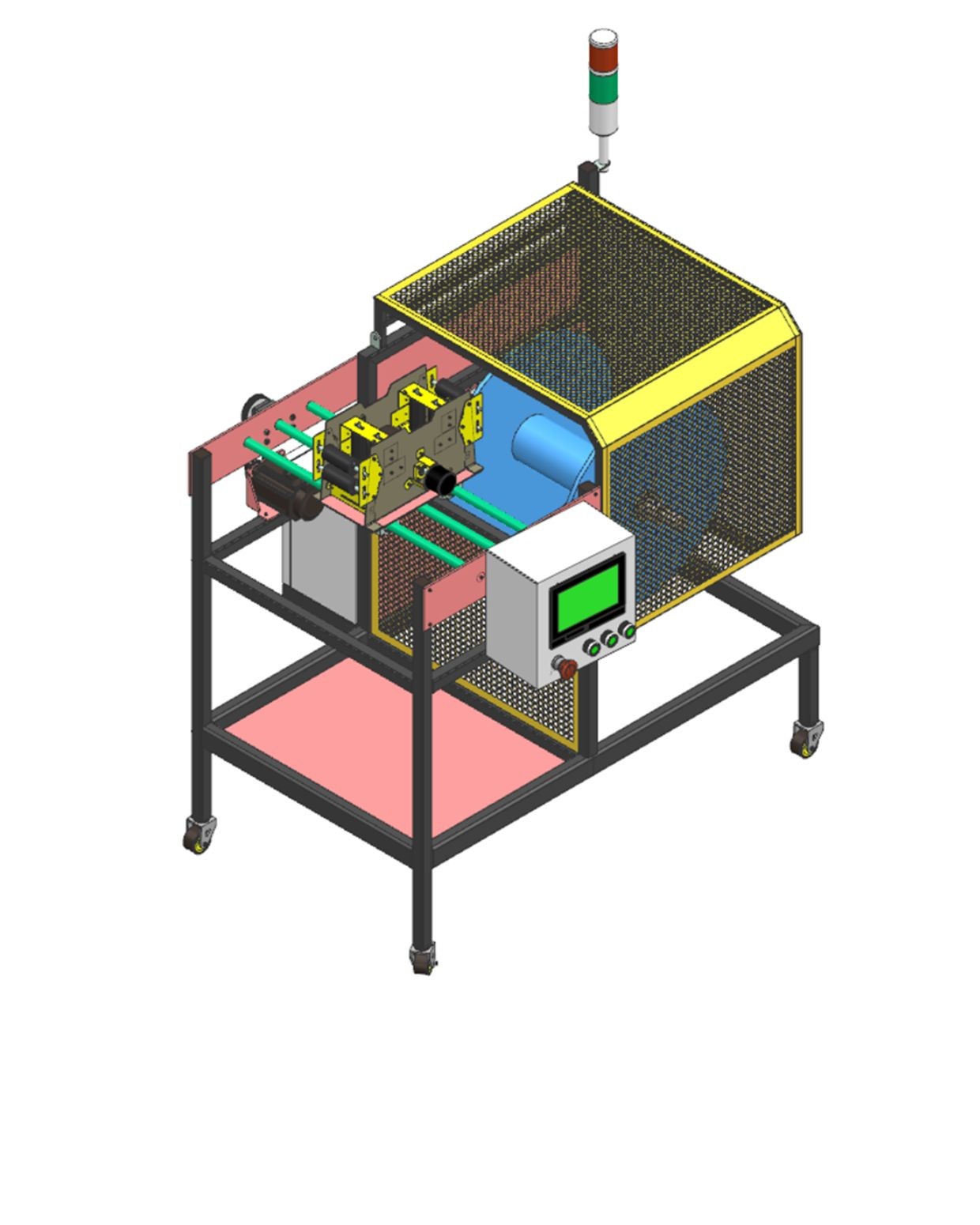

A welding JIG is a specialized type of JIG used in the welding process to hold and position metal parts in place, ensuring high accuracy and uniformity of welds. It helps prevent the movement of parts during welding, allowing the welder or machinery to make precise welds in the correct positions according to the design, thereby improving product quality.

Benefits of Welding JIGs:

- Ensures high accuracy: holds metal parts in the correct position, helping create precise welds and minimizing errors.

- Increases productivity: the welding process is faster since less time is spent on alignment.

- Improves safety: Reduces the risk of parts shifting during welding, making the job safer.

- Reduces thermal distortion: Securing parts tightly helps minimize warping or deformation caused by heat during welding.

Common Types of Welding JIGs:

- Fixed welding JIGs: Used for parts or products with fixed shapes and sizes.

- Flexible welding JIGs: Can be adjusted to fit various shapes and sizes.

- Automatic welding JIGs: Often integrated with robotic welding systems to support automated welding processes.

They are commonly used in manufacturing industries, especially in automotive, machinery, and steel structure production, helping products meet high-quality standards and reducing production costs.

Contact: Nguyen Xuan Canh (Mr. Orion) (Sales Manager) - Phone: (+84) 905.648.436 - Email: tas.info@tasvina.com

Reviews

There are no reviews yet.