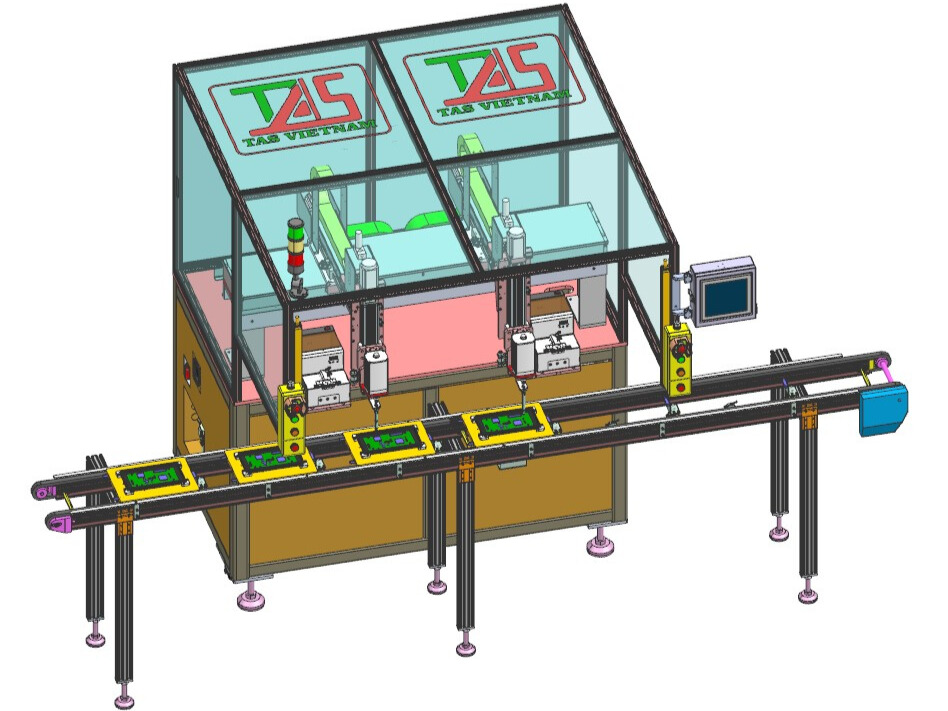

Description

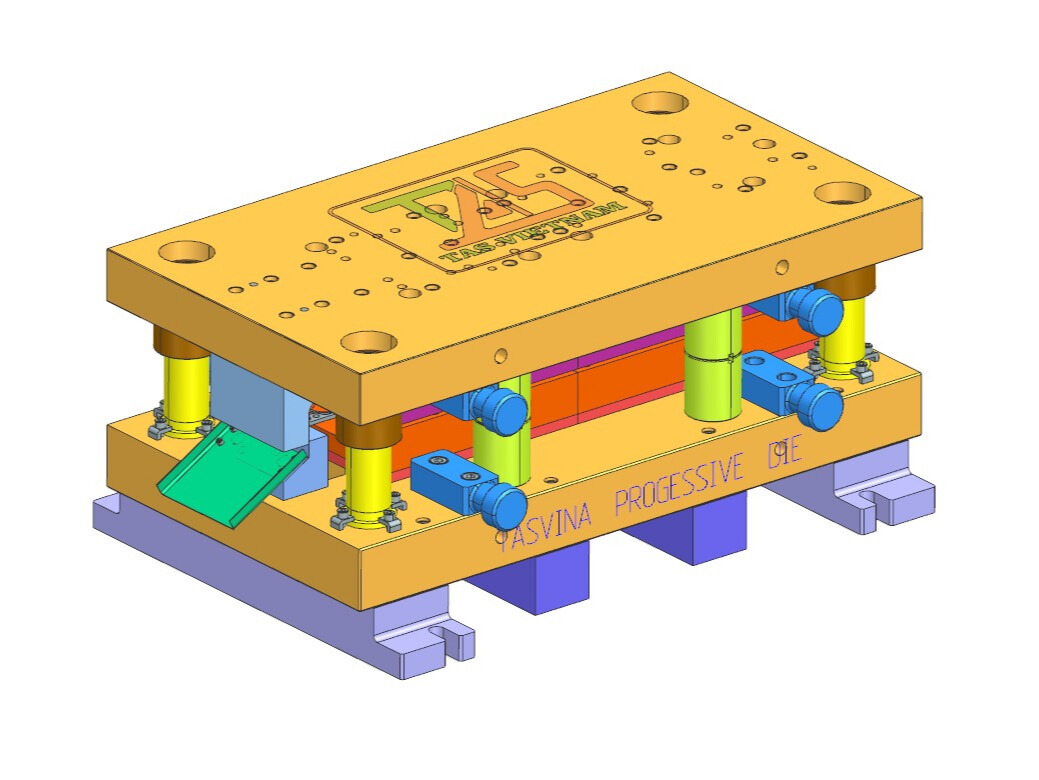

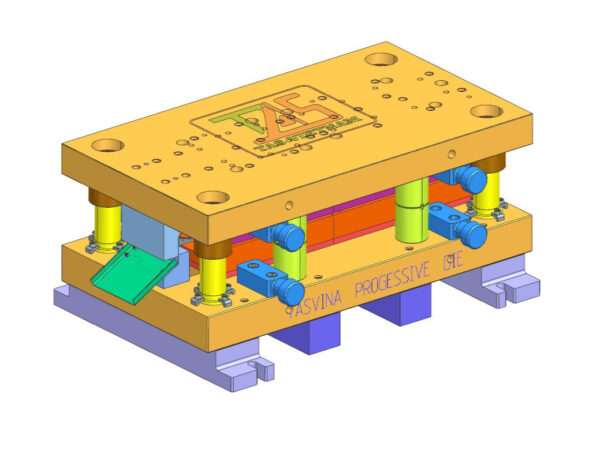

A stamping die is a tool used in metalworking processes, particularly for shaping and cutting parts from metal sheets. A stamping die typically consists of two main components: the upper die (die) and the lower die (punch), which work together to perform operations such as stamping, cutting, bending, and shaping materials.

There are various types of stamping dies, including:

- Cutting Die: Used to cut shapes or parts from metal sheets.

- Bending Die: Creates bends or 3D shapes on the metal surface.

- Deep Drawing Die: Used to elongate or add depth to materials, suitable for producing items shaped like boxes or tubes.

- Progressive Die: Performs multiple steps in a single cycle, optimizing production speed.

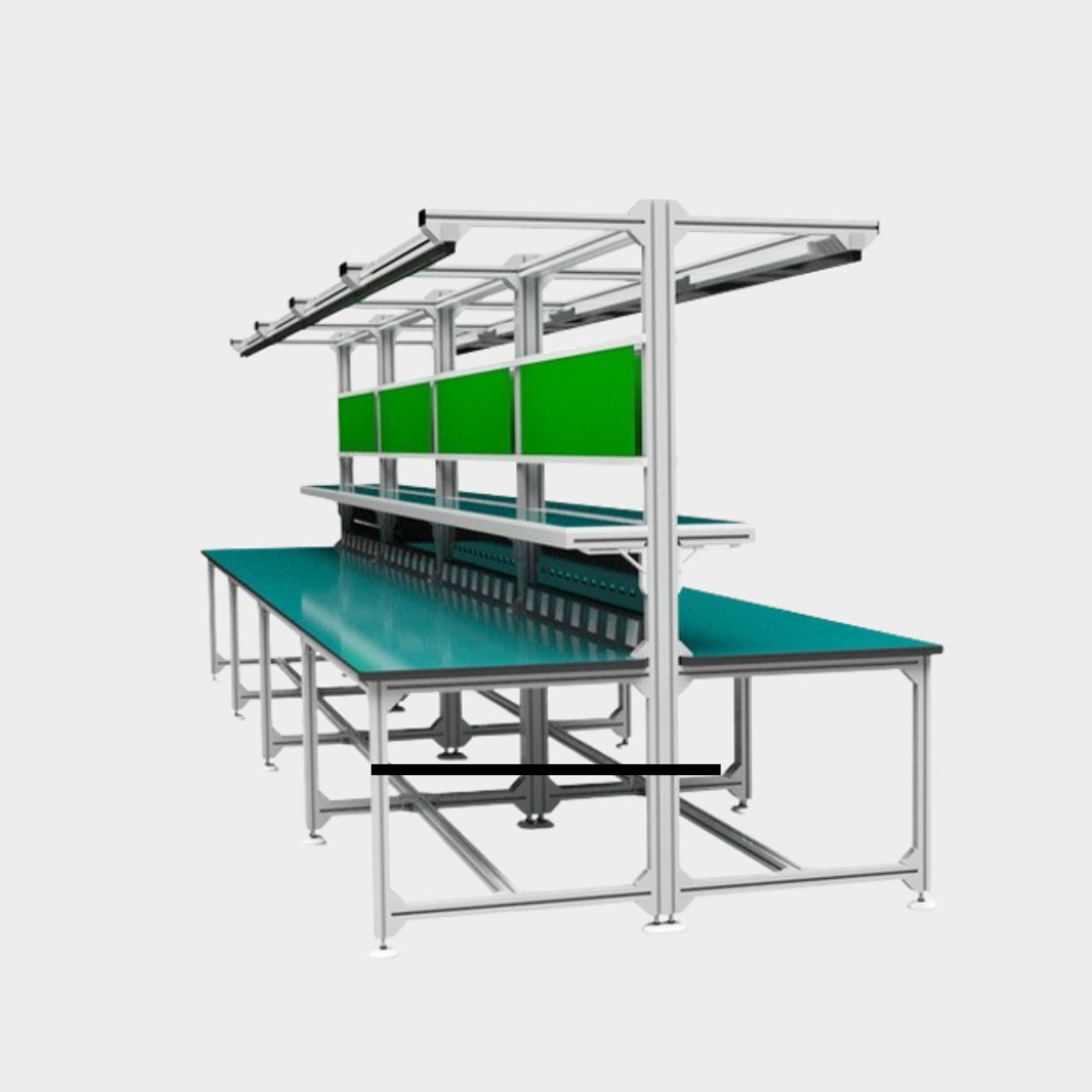

Stamping dies play a crucial role in industries such as automotive, electronics, and appliance manufacturing, helping to produce uniform products with high precision and optimized production costs.

Contact: Nguyen Xuan Canh (Mr. Orion) (Sales Manager) Phone: (+84) 905.648.436 Email: tas.info@tasvina.com

Reviews

There are no reviews yet.