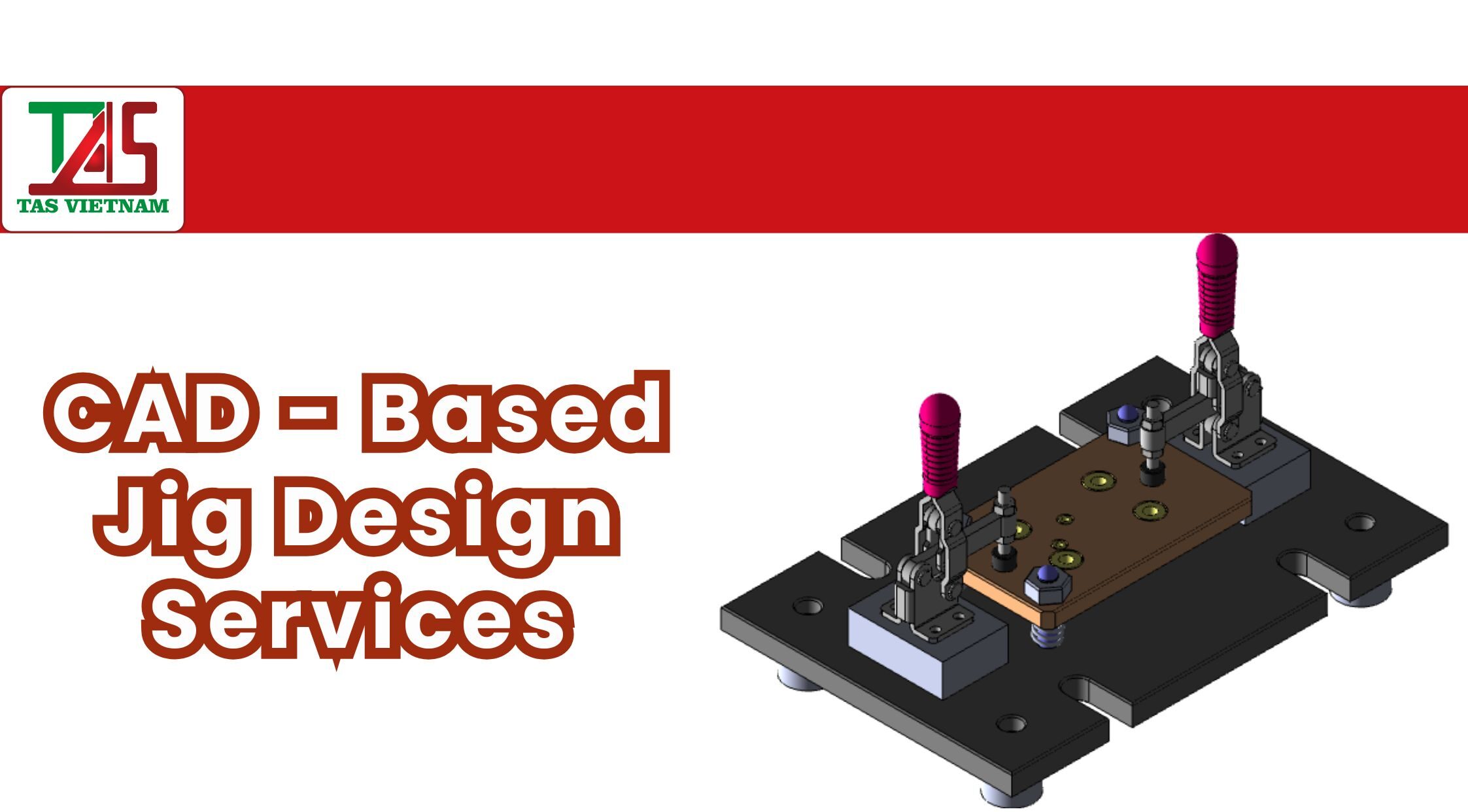

What Is Jig Design?

Jig Design, or the design of jigs and fixtures, refers to the development of specialized tools that position, clamp, and support workpieces during manufacturing processes. These devices are essential in increasing accuracy, stability, and safety throughout production, especially in automated or semi-automated mechanical manufacturing lines.

At TASVINA, we offer CAD-based jig design services to help manufacturers optimize their workflows, reduce human error, and streamline fabrication. Whether you need a completely new jig or modifications to an existing one, TASVINA delivers tailor-made solutions with precision and performance at the core.

Types of Jigs We Design

We cover a full range of jig design categories, including:

- JIG Welding – Used to hold and align parts during welding for precision and consistency.

- JIG Checking – Inspection jigs designed for quality control and dimensional checks.

- JIG Assembly – Fixtures that support accurate positioning and assembly of components.

- JIG Machining – Jigs that guide and stabilize parts for CNC machining and manual operations.

Why Choose TASVINA for Jig Design?

✅ Enhanced Production Efficiency

Our jigs are designed to reduce setup time, improve process flow, and speed up manufacturing cycles, helping you produce more in less time.

✅ Increased Accuracy and Product Quality

By securing the workpiece in place, jigs eliminate positioning errors and enhance dimensional consistency, resulting in higher product quality.

✅ Improved Operator Safety

Our jigs minimize manual adjustments, reducing the likelihood of accidents and protecting your workforce in high-speed production environments.

✅ Custom CAD Designs

We create 3D and 2D jig designs using professional CAD software, ensuring that every solution is customized to meet your exact requirements—whether you’re starting from scratch or upgrading an existing setup.

✅ All-In-One Support

From concept development to final design documentation, TASVINA provides end-to-end service. We don’t just design—we optimize, simulate, and deliver ready-to-use CAD files that meet industry standards.

Our Jig Design Process

- Requirement Analysis

We begin by understanding your production needs, component specifications, and current challenges. - CAD Modeling

Our team creates detailed 2D and 3D CAD designs using tools like SolidWorks, AutoCAD, or Siemens NX. - Design Optimization

We simulate usage, adjust ergonomics, and refine jig structures for efficiency and durability. - Review & Adjustment

We share drafts for client review and make adjustments based on feedback to ensure complete satisfaction. - Final Delivery

The final design files are delivered in industry-standard formats, ready for prototyping or direct implementation.

Industries We Serve

Our CAD jig design solutions are used across a variety of industries:

- Automotive & Motorbike Manufacturing

Jigs for welding frames, checking tolerances, and assembling engine components. - Electronics Manufacturing

Precision jigs for circuit board inspection and chip placement. - Heavy Industry & CNC Machining

Custom fixtures for milling, turning, drilling, and cutting large mechanical parts. - Home Appliances & Consumer Goods

Jigs that support fast and consistent production of complex assemblies.

Benefits of Partnering with TASVINA

- Over a decade of experience in CAD design and mechanical engineering

- Multidisciplinary design team with deep knowledge of production systems

- Agile turnaround time and responsive technical support

- Competitive pricing with high-quality deliverables

- Comprehensive after-sales service

Let TASVINA Be Your Jig Design Partner

If you’re looking for a reliable and skilled partner for jig design, TASVINA is here to support you. Our expertise in CAD-based jigs and fixtures ensures your production line runs smarter, safer, and faster.