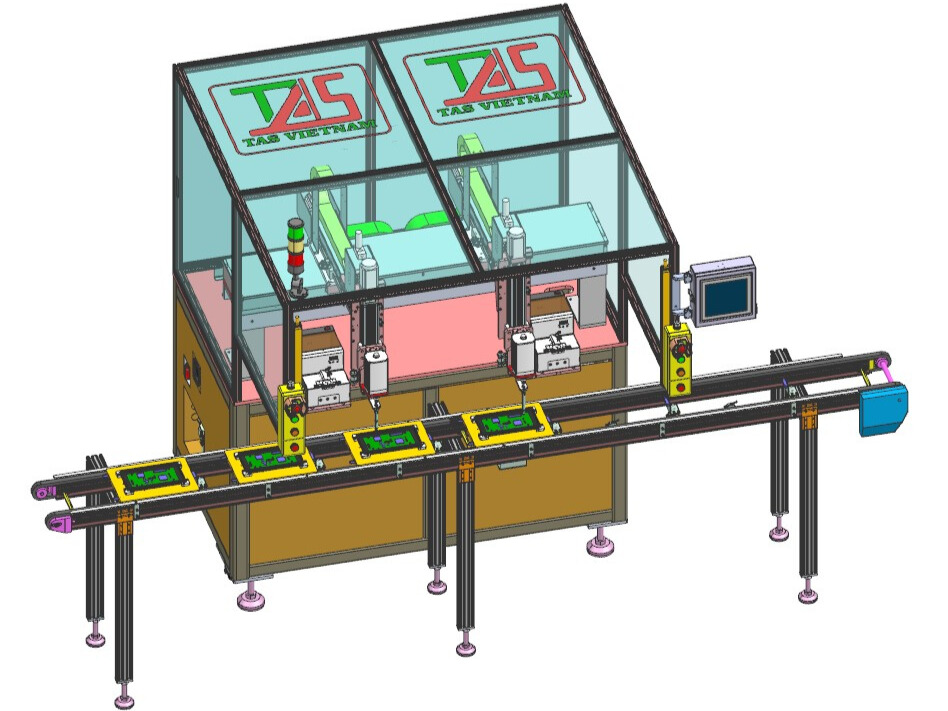

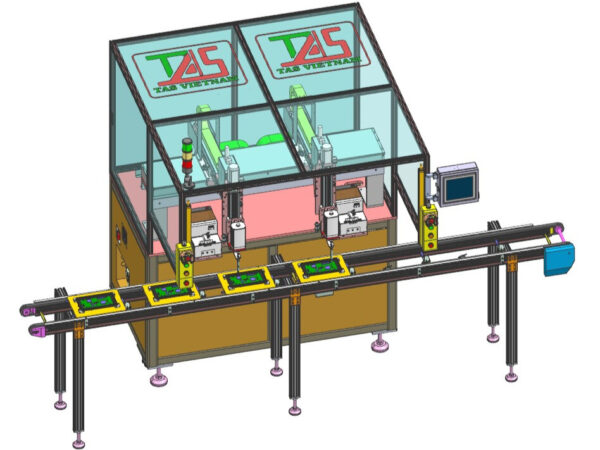

Description

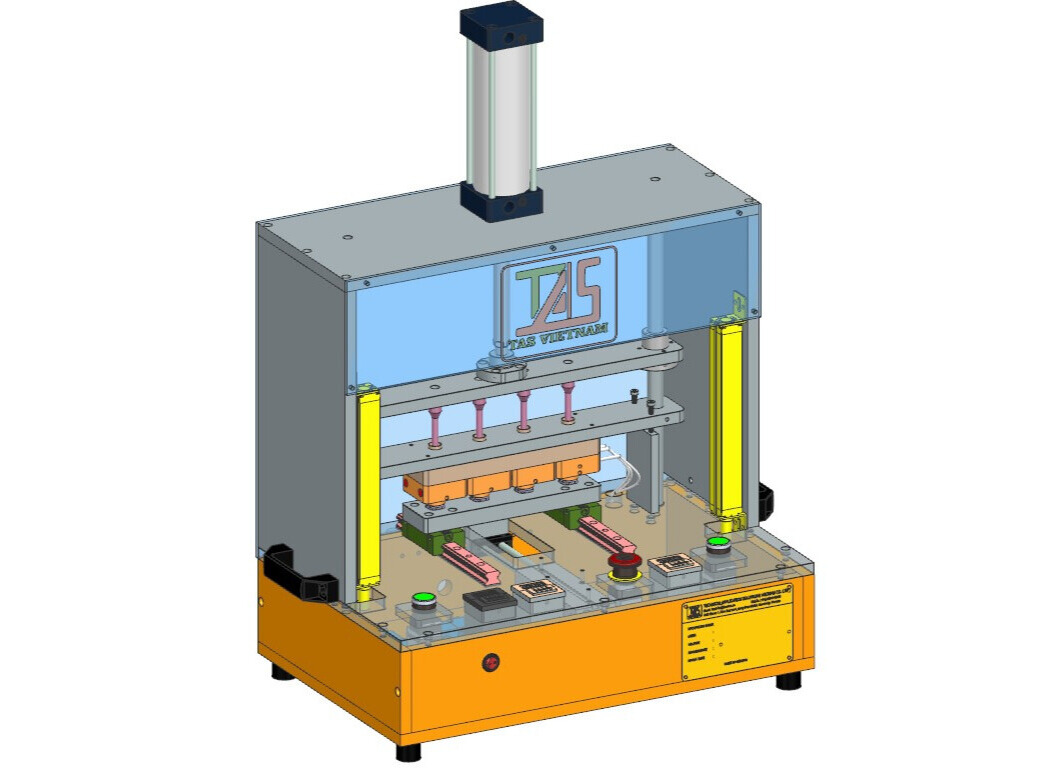

An automatic screw machine is a device used to automatically tighten screws into products, commonly used in industrial production lines to increase efficiency and accuracy in assembly. The automatic screw driving machine saves time and human labor, especially effective when working with a large number of assembly parts that require screwing.

Main Components of an Automatic Screw Machine:

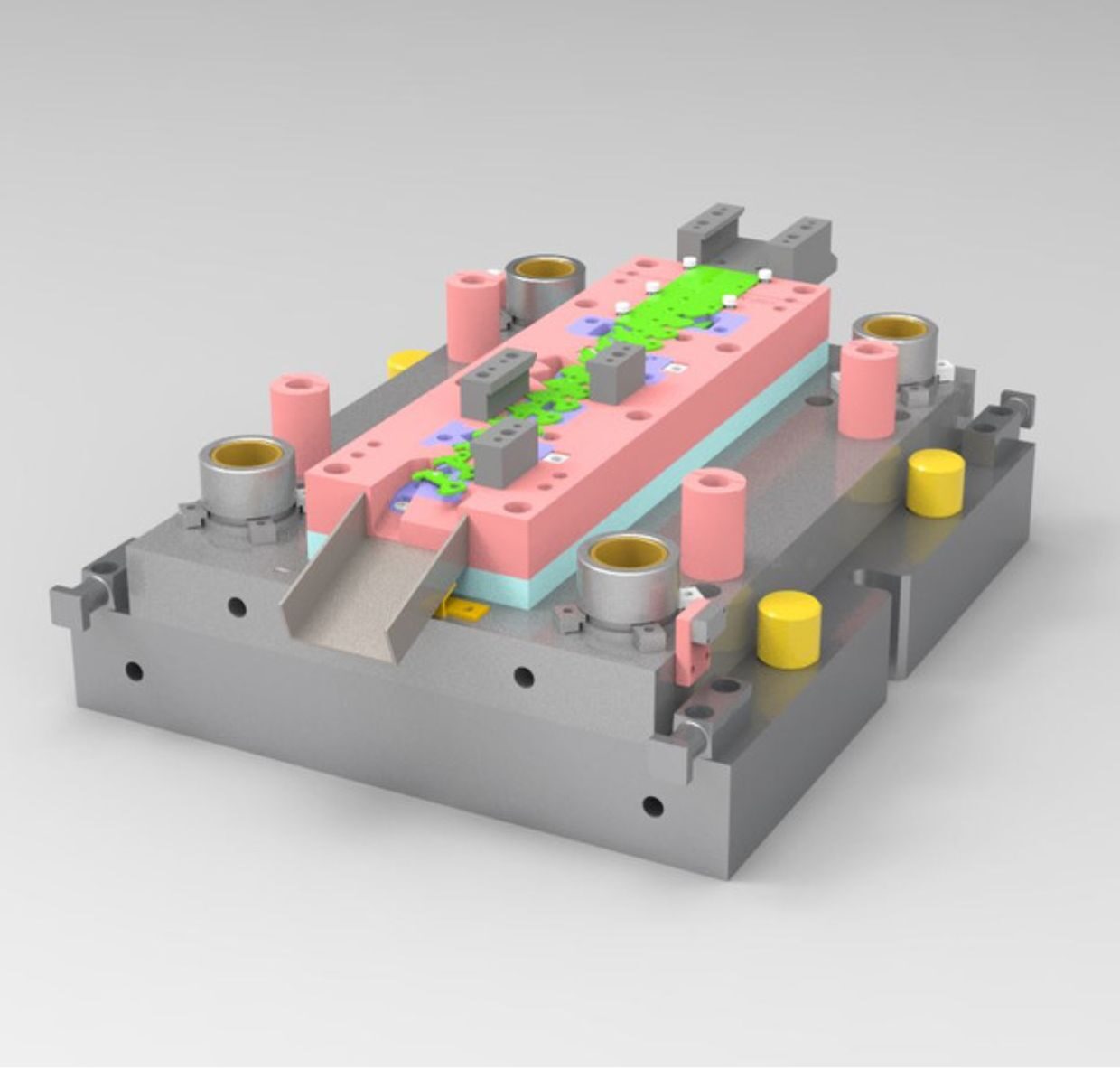

- Automatic Screw Feeder: Ensures screws are continuously and accurately fed to the correct position during operation.

- Controller: Typically, a PLC or industrial computer that controls the screw driving process and ensures precision.

- Screw Driving Head: Can be single or multi-head, allowing for multiple screws to be driven simultaneously or for automatic movement to different positions.

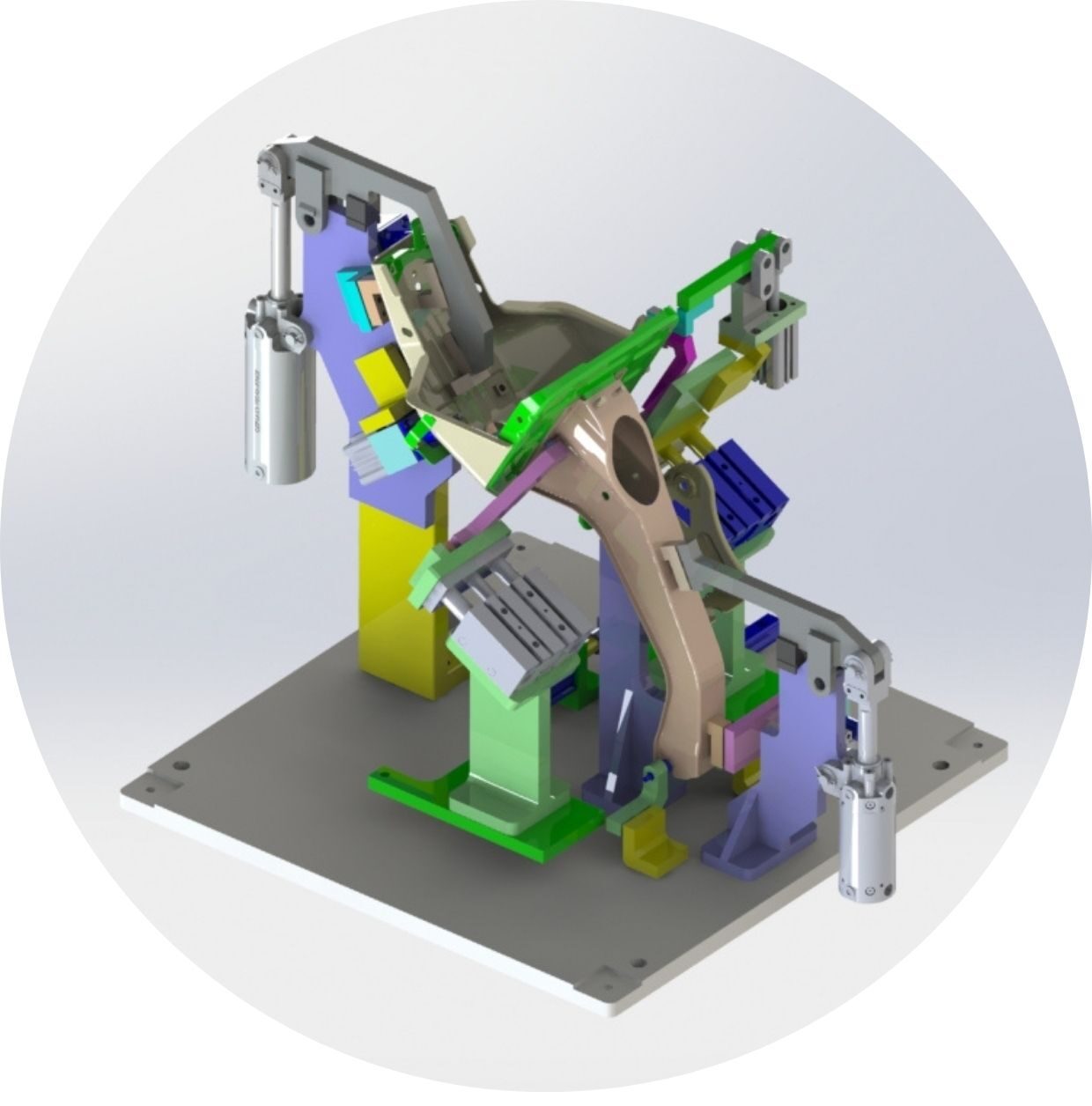

- Robot Arm (if equipped): Automatic screw driving machines with integrated robotic arms can move to the required positions for screwing, meeting the needs of automated assembly lines.

Advantages of an Auto Screw Machine:

- Increased Efficiency: Fast and stable screw driving speed boosts productivity.

- High Precision: Adjustable screw driving force and depth ensure consistent assembly quality.

- Reduced Human Error: Limits mistakes caused by operator error.

- Process Automation: Enhances automation in the production line, reducing manual labor and increasing production efficiency.

Applications: Automatic screw driving machines are commonly used in industries such as electronics, automotive manufacturing, home appliances, and products requiring high-precision assembly with multiple components.

Contact: Nguyen Xuan Canh (Mr. Orion) (Sales Manager) - Phone: (+84) 905.648.436 - Email: tas.info@tasvina.com

Reviews

There are no reviews yet.