Introduction

The global automotive industry is undergoing one of the most significant transformations in its history. The shift toward electrification and intelligent connectivity is redefining how vehicles are designed, developed, and experienced. As automakers race to build more sustainable and data-driven mobility solutions, automotive module design has emerged as the backbone of innovation.

At TASVINA, we specialize in automotive engineering solutions — from CAD, CAE, and CAM services to automation and simulation — empowering global partners to accelerate product development and ensure top-tier quality. This article explores how modular design enables the transition to electrified and smart vehicle platforms, and why it’s essential for the future of automotive engineering.

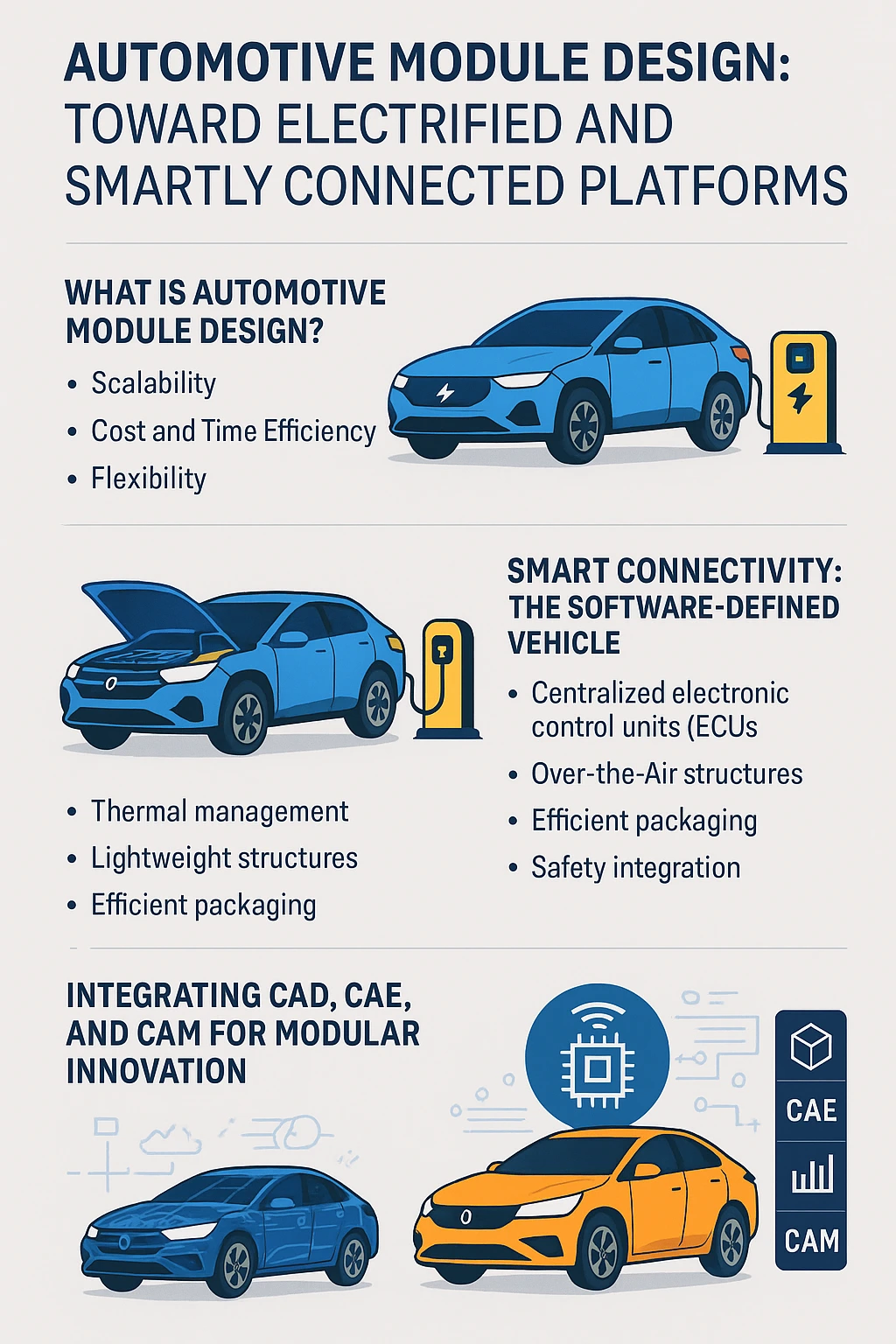

1. What Is Automotive Module Design?

Automotive module design refers to the systematic development of vehicle components as independent yet interoperable units. Instead of designing every part from scratch, engineers can reuse, modify, and integrate modules (e.g., battery systems, infotainment units, drive modules, etc.) across different vehicle models.

This modularization offers three main advantages:

- Scalability – Easier adaptation of design for various models and market segments.

- Cost and Time Efficiency – Reusing proven modules significantly reduces R&D expenses.

- Flexibility – Facilitates faster technology integration, such as electric powertrains or IoT systems.

2. The Transition to Electrification

Electrification reshapes vehicle architecture from the ground up. Instead of an engine-centric layout, EV platforms rely on battery packs, e-motors, and power electronics as the core modules.

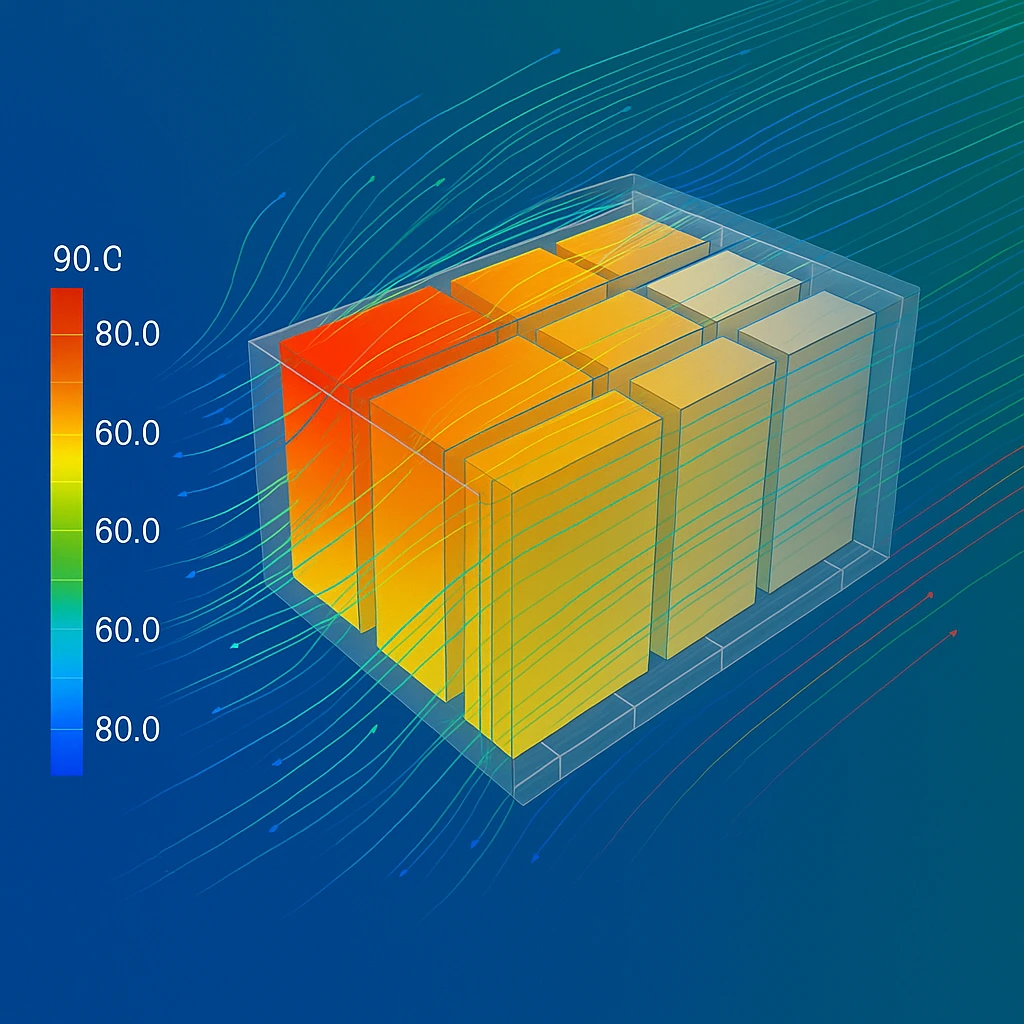

Key Design Challenges:

- Thermal management for high-voltage batteries

- Lightweight structures to offset battery weight

- Efficient packaging for electrical systems

-

Safety integration for high-voltage circuits

To meet these challenges, TASVINA’s CAE simulation services help optimize battery enclosure performance, cooling systems, and structural integrity. By combining finite element analysis (FEA) and computational fluid dynamics (CFD), we provide clients with deep insights into thermal behavior, vibration durability, and crash safety before prototyping.

3. Smart Connectivity: The Software-Defined Vehicle

As vehicles become more connected, the boundary between hardware and software is fading. The modern car is now a “computer on wheels”, driven by real-time data and AI-based decision-making.

The Rise of the Software-Defined Vehicle (SDV)

- Centralized electronic control units (ECUs)

- Over-the-air (OTA) updates

- Cloud-based diagnostics

- Autonomous driving integration

In this ecosystem, module design ensures that electronic and mechanical systems can evolve independently yet communicate seamlessly. TASVINA’s automation and embedded engineering teams develop and validate these systems using model-based design and virtual testing environments.

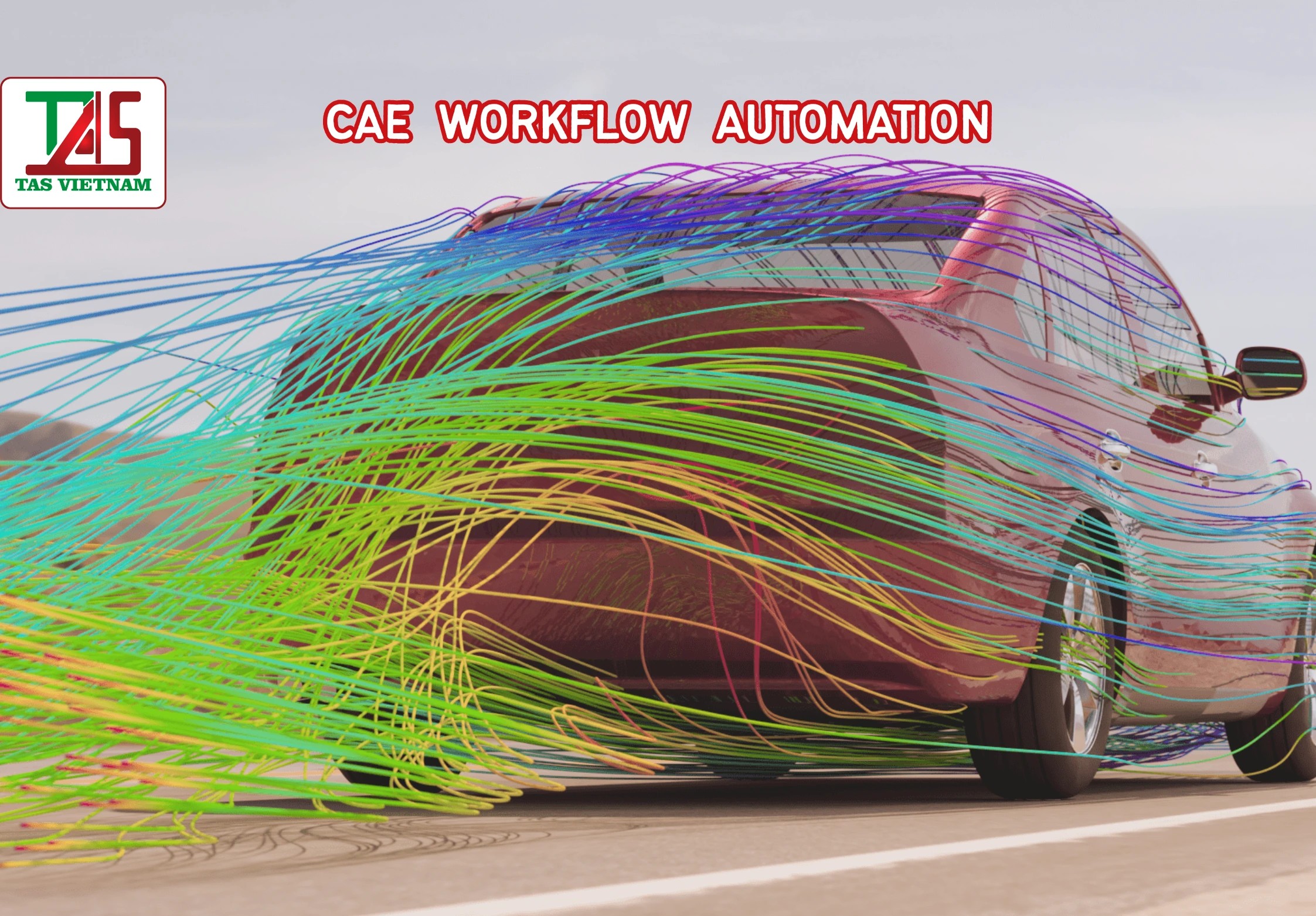

4. Integrating CAD, CAE, and CAM for Modular Innovation

At TASVINA, we view CAD, CAE, and CAM not as isolated tools but as a continuous digital thread that connects concept to production.

- CAD (Computer-Aided Design): Enables precise 3D modeling and parametric control of modules.

- CAE (Computer-Aided Engineering): Simulates performance under real-world conditions.

- CAM (Computer-Aided Manufacturing): Converts virtual modules into manufacturable components.

Through this integration, we support clients in achieving:

- Faster design iterations

- Reduced production costs

- Improved cross-functional collaboration

- Shorter time-to-market

Our engineers utilize industry-leading software such as CATIA, NX, and ANSYS, along with advanced PLM (Product Lifecycle Management) platforms, to ensure full traceability and efficiency throughout the product lifecycle.

5. Global Collaboration and Localization in Vietnam

Vietnam has become an emerging hub for automotive R&D outsourcing. With its skilled engineering talent and competitive cost base, it’s an ideal destination for companies seeking both global standards and local agility.

TASVINA acts as a strategic engineering partner for international clients operating in Vietnam. Our multicultural teams bridge the gap between Asian manufacturing ecosystems and Western engineering standards, ensuring technical excellence, communication efficiency, and IP protection.

6. The Road Ahead: Electrified, Connected, and Sustainable

The automotive future is defined by three pillars:

- Electrification – Clean energy propulsion systems

- Connectivity – Seamless communication between vehicles, infrastructure, and cloud

- Automation – Autonomous and assisted driving capabilities

By adopting a modular design philosophy, automakers can continuously upgrade these pillars without redesigning the entire vehicle. This approach not only improves efficiency but also aligns with sustainability goals — reducing waste, energy consumption, and carbon footprint.

Conclusion

In the race toward smarter, greener mobility, automotive module design is the foundation for innovation. As EVs and connected vehicles dominate the next decade, companies that embrace modularization will lead the transformation.

TASVINA is proud to be part of this journey — supporting global clients with comprehensive engineering solutions that combine technical expertise, digital innovation, and a commitment to excellence.