Automotive Plastic & Metal Component Development Services | CAD Design by TASVINA

In today’s rapidly evolving automotive industry, the demand for innovative, lightweight, and precisely engineered components is higher than ever. At TASVINA, we specialize in CAD-based development of plastic and metal components for the automotive sector, offering end-to-end design and engineering solutions that meet the highest technical and aesthetic standards.

Comprehensive Component Development for Modern Vehicles

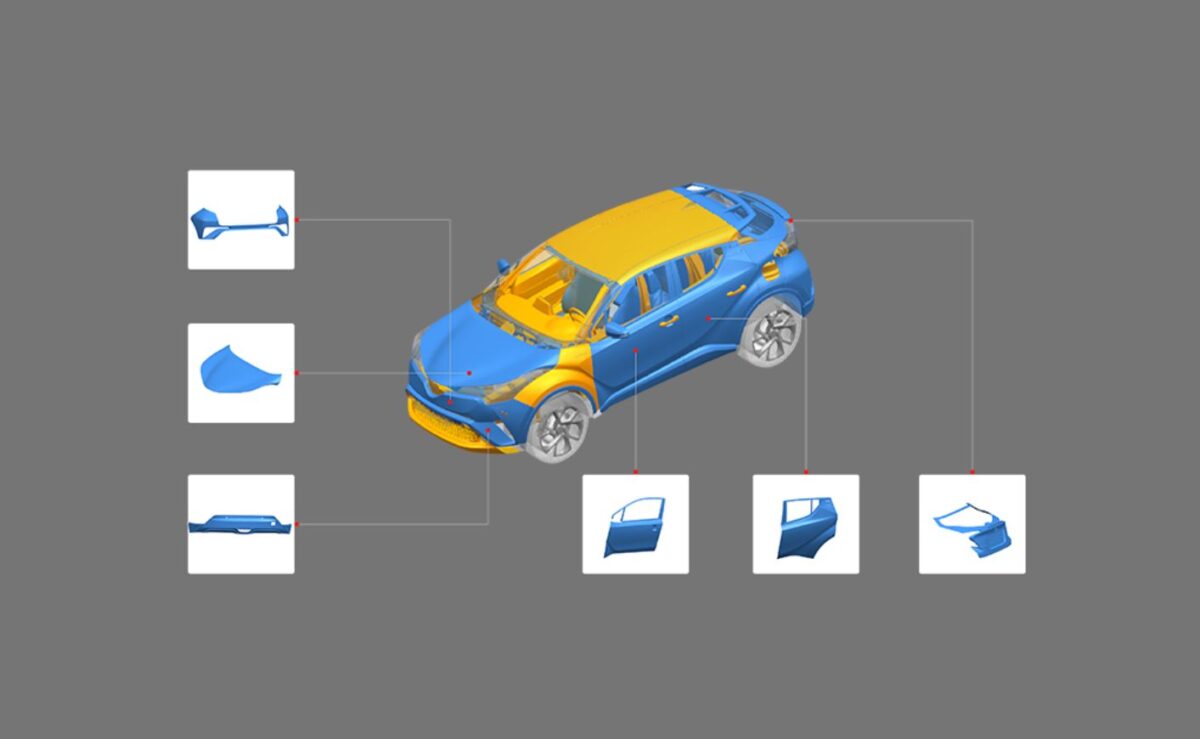

Our automotive component development services cover a wide spectrum of vehicle parts, including:

- Interior components

- Exterior parts

- Chassis systems

- Body-in-white (BIW) structures

From conceptualization to CAD modeling and final design validation, TASVINA is your trusted partner in transforming design visions into high-performance automotive solutions.

Interior Component Design

The car interior is not just about comfort—it’s about functionality, safety, and aesthetics. We develop plastic and metal interior parts such as dashboards, center consoles, door panels, trim components, and seat structures. Our CAD engineers ensure that every component aligns with ergonomic design principles and seamlessly integrates into the overall vehicle architecture.

Using advanced CAD tools, we create 3D models that simulate real-world usage conditions, enabling our clients to optimize for space utilization, weight reduction, durability, and manufacturability.

Exterior Component Design

Exterior parts define the visual identity of a vehicle and must withstand various environmental stresses. We design bumpers, grills, side mirrors, fenders, spoilers, and other exterior elements using high-precision CAD modeling to ensure aerodynamic performance, structural integrity, and a flawless surface finish.

We work closely with OEMs and Tier-1 suppliers to align with automotive styling trends and ensure compliance with global safety and quality standards.

Chassis and Suspension Component Development

The chassis forms the structural backbone of any vehicle. Our engineering team develops metal chassis parts and suspension elements that offer the ideal balance between strength, rigidity, and weight.

Through finite element analysis (FEA) and dynamic simulation, we validate all chassis components for fatigue resistance, crashworthiness, and manufacturability. Our solutions help clients improve vehicle handling, safety, and fuel efficiency.

Body-in-White (BIW) Structure Design

TASVINA also supports the development of Body-in-White (BIW) structures, including floor assemblies, pillars, roof rails, and cross-members. These metal components are essential for maintaining vehicle integrity during collisions and providing structural support.

Using industry-standard CAD platforms such as CATIA, NX, and SolidWorks, we design and optimize BIW parts for mass production feasibility, ease of assembly, and compliance with international crash safety regulations.

Why Choose TASVINA?

- Expertise in both plastic and metal parts

- Proven track record with global automotive clients

- Advanced CAD capabilities including 3D modeling, FEA, and design for manufacturability (DFM)

- Strict adherence to automotive industry standards

- Collaborative development with your R&D and engineering teams

Whether you are launching a new vehicle platform or upgrading an existing model, TASVINA provides the technical excellence and design innovation you need to stay ahead in the competitive automotive landscape.

Get in Touch

Ready to bring your automotive component ideas to life? Contact TASVINA today to learn more about our CAD-based plastic and metal part development services for interiors, exteriors, chassis, and body structures. Let’s engineer the future of mobility together.