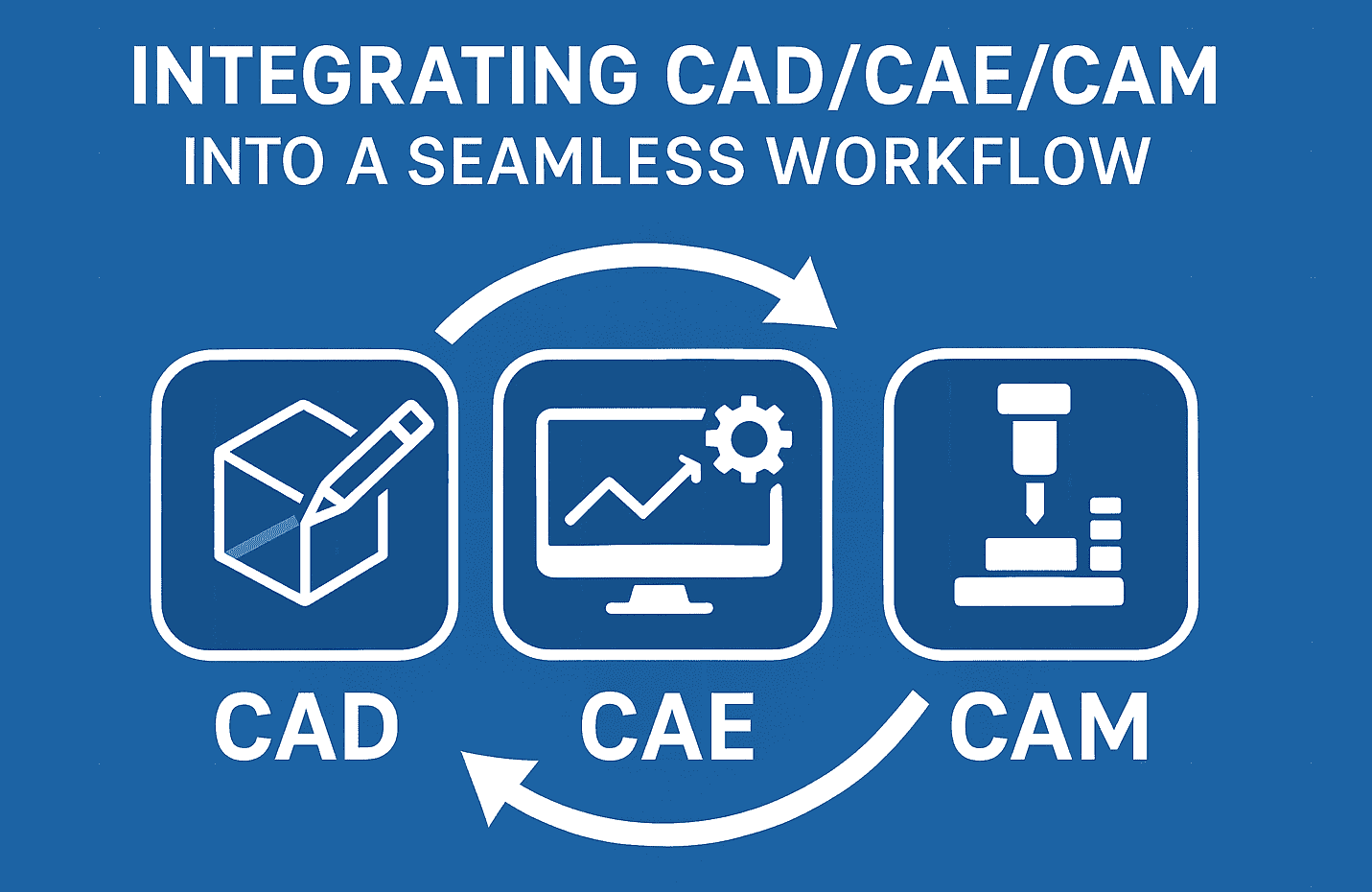

In today’s era of digital engineering and smart manufacturing, the boundaries between CAD (Computer-Aided Design), CAE (Computer-Aided Engineering), and CAM (Computer-Aided Manufacturing) are rapidly fading. Many experts and industry leaders have long envisioned a seamless integration of these systems into one continuous digital thread — from conceptual design to product validation and automated production. But is this seamless integration a realistic goal, or merely an ambitious illusion?

At TASVINA, where we specialize in advanced CAD/CAE/CAM solutions, this question is not just theoretical — it directly shapes how we approach innovation and help our clients stay competitive in a fast-changing manufacturing landscape.

1. Understanding the Traditional Divide

Historically, CAD, CAE, and CAM operated as separate stages within the product development process.

- CAD focuses on geometry creation and design modeling.

- CAE deals with analysis and simulation — testing designs virtually before physical prototyping.

- CAM converts validated designs into machine-readable manufacturing instructions.

This division, while logical in the early days of digital engineering, often resulted in data silos and workflow fragmentation. Designers had to export files from CAD to CAE, reimport results, and then adjust geometry manually before sending data to CAM. Each transition introduced the risk of data loss, version mismatch, and reduced efficiency.

In the age of high customization and short product life cycles, this disconnection has become an obstacle to innovation.

2. The Case for Seamless Integration

The vision of CAD/CAE/CAM integration is driven by the demand for digital continuity — ensuring that every stage of the product lifecycle is connected through a unified data model.

A seamless digital thread enables:

- Design consistency — geometric and simulation data remain synchronized.

- Faster time-to-market — reducing redundant rework between departments.

- Improved product quality — by integrating feedback from simulation directly into design decisions.

- Automation and smart manufacturing — CAM receives real-time updates when designs change.

At TASVINA, we see this not as a luxury, but as a strategic necessity for organizations embracing Industry 4.0 principles.

3. Technological Drivers Behind Integration

Several technological advancements are making this integration increasingly feasible:

- Cloud-based PLM (Product Lifecycle Management)

Cloud platforms provide centralized data storage, ensuring that CAD, CAE, and CAM systems access the same digital twin in real time. - AI-driven optimization and simulation

Artificial intelligence and machine learning are helping to automate simulation and design validation, enabling faster iterations and smarter decision-making. - Model-based definition (MBD)

MBD embeds all manufacturing and tolerance information directly into 3D CAD models, removing the need for separate 2D drawings and improving communication between design and manufacturing. - Interoperable file formats and APIs

Modern CAD/CAE/CAM tools are adopting open standards such as STEP, IGES, and JT, making cross-platform data exchange far smoother than before. - These advancements are not just bridging the technical gap; they are transforming how engineering teams collaborate and innovate.

4. The Human and Organizational Challenge

However, true integration goes beyond technology. It requires organizational alignment and cultural adaptation. Many companies still treat CAD, CAE, and CAM as isolated departments with distinct KPIs and workflows.

At TASVINA, we’ve observed that successful integration projects depend heavily on:

- Change management — helping teams adapt to unified digital workflows.

- Upskilling engineers — ensuring they are proficient across multiple tools and simulation environments.

- Collaborative mindset — encouraging early collaboration between design, simulation, and manufacturing teams.

Technology can enable integration, but people must drive it.

5. Illusion or Inevitable Future?

So, is a fully seamless CAD/CAE/CAM integration an illusion? Perhaps a few years ago, the answer would have been “yes.” But with today’s digital twin technology, AI-enhanced simulation, and real-time data synchronization, the industry is undeniably moving toward a unified, intelligent engineering ecosystem.

Still, perfection remains a moving target. Every organization is at a different stage of digital maturity. Some have already achieved near-seamless integration through end-to-end platforms; others are just beginning their digital transformation journey. What matters most is the strategic roadmap — knowing where to start, how to integrate gradually, and how to measure ROI effectively.

6. TASVINA’s Vision: Engineering the Digital Continuum

At TASVINA, we believe that integration is not a future dream — it is a present opportunity. Our expertise in CAD/CAE/CAM consulting, simulation-driven design, and automated manufacturing solutions enables clients to connect every phase of the product lifecycle into one digital continuum.

We help organizations:

- Build CAD-CAE data synchronization pipelines.

- Implement parametric and simulation-driven design workflows.

- Integrate CAM automation and toolpath optimization within their digital twin framework.

- Adopt cloud-based collaboration and PLM systems for real-time teamwork.

Through these solutions, TASVINA empowers engineers to design smarter, validate faster, and manufacture better — turning the dream of seamless integration into tangible competitive advantage.

7. Conclusion

The integration of CAD, CAE, and CAM is not a fleeting industry buzzword. It represents a paradigm shift in how we conceptualize, design, and manufacture products in the digital age. The question is no longer whether integration will happen, but how fast organizations can adapt to it.

For companies aiming to stay relevant in the era of digital manufacturing and smart engineering, embracing this integrated approach is not optional — it’s inevitable.

At TASVINA, we are proud to stand at the forefront of this transformation — helping industries bridge the gap between imagination and production, between design and reality.