In modern engineering, physical testing has always been the cornerstone of verifying product safety, durability, and performance. However, with the rapid advancement of Computer-Aided Engineering (CAE), a big question arises: Can CAE fully replace physical testing?

This article explores the role of CAE, its benefits, limitations, and why the integration of both methods is the true path to product innovation.

What is CAE & Its Role in the Design Cycle?

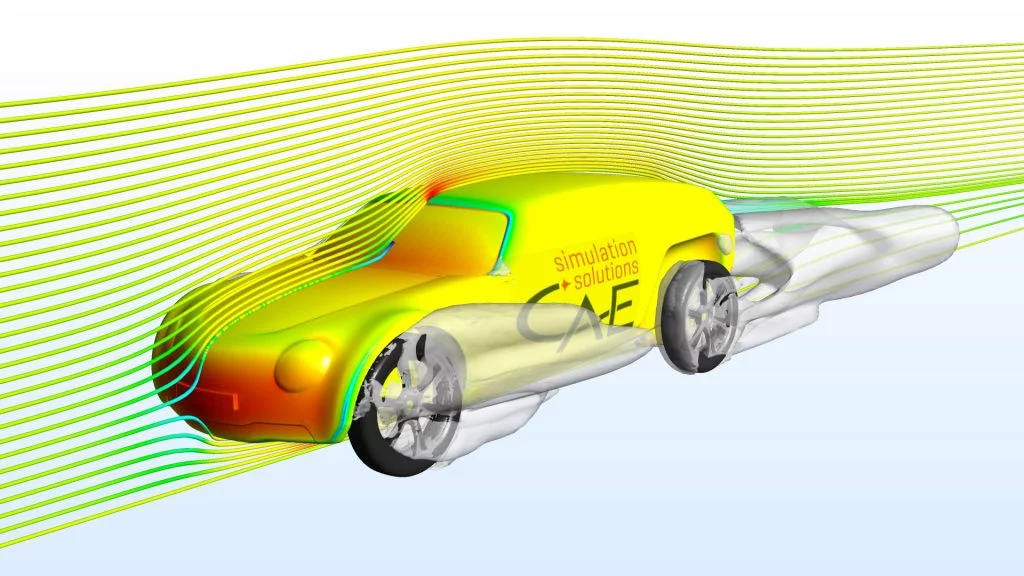

CAE is a computer-aided engineering tool used to solve structural, thermal, fluid, and dynamic problems through techniques such as finite element analysis (FEA), computational fluid dynamics (CFD), and multi-body dynamics (MBD).

With the growth of computer power, CAD technology, and accurate material data, CAE has become an essential step in the product development chain: CAD → CAE → CAM.

Key capabilities of CAE include:

- Exploring multiple design concepts quickly.

- Reducing prototype dependency and cutting initial costs.

- Predicting weak points such as overload, thermal stress, fatigue, or impact issues before manufacturing.

Major Advantages of CAE Before Physical Testing

- Time & Cost Savings

Instead of building multiple prototypes, CAE allows engineers to simulate, test, and optimize virtually in a much shorter timeframe. - Risk Reduction

CAE can highlight structural weaknesses, material fatigue, and design flaws early, minimizing costly late-stage redesigns. - Production Optimization

By simulating various conditions, CAE supports the choice of materials and processes that balance performance with cost-efficiency. - Certification Support

Simulation data provides objective evidence that can shorten the physical validation and certification process.

Limitations of CAE & Why Physical Testing Remains Essential

While CAE is powerful, it still has boundaries:

- Modeling Assumptions: Accuracy depends on input data (material properties, load cases, environmental conditions). Any mismatch can lead to misleading results.

- Unpredictable Real-World Factors: Not all conditions (manufacturing errors, extreme environments, or random accidents) can be captured by simulation.

- Regulatory Demands: Industries such as automotive, aerospace, and energy require physical tests to comply with safety standards and legal certification.

- Expertise & Resources: Building accurate CAE models requires skilled engineers, high-performance computing, and validated data.

The Optimal Approach: Combining CAE & Physical Testing

Rather than replacing one with the other, leading companies use both CAE and physical testing in a complementary way:

- Start with CAE: Filter design concepts, explore possibilities, and narrow down the most promising solutions.

- Validate with Physical Testing: Verify simulations with real-world prototypes, ensuring safety and compliance.

- Correlation Between Both: Comparing CAE results with experimental data improves the reliability of future simulations.

- Reduce Physical Test Scope: CAE helps minimize the number of prototypes and tests, focusing physical trials only where necessary.

This integrated workflow accelerates development while ensuring both efficiency and safety.

Can CAE Fully Replace Physical Testing?

The short answer is no.

CAE is an invaluable tool for:

- Fast design exploration

- Early cost and risk reduction

- Process optimization

But physical testing remains irreplaceable for:

- Final safety validation

- Real-world feedback

- Regulatory compliance

TASVINA: Where CAE Meets Real-World Testing

At TASVINA, we help clients maximize the synergy between simulation and testing through a proven workflow:

- Import CAD & material data

- Build models (FEA/CFD/MBD) and realistic assumptions

- Run simulations & mesh analysis

- Correlate results with physical test data

- Deliver reports, design recommendations, and test plans

Why choose TASVINA?

- Expertise in automotive, aerospace, and industrial equipment

- A dedicated team of CAE specialists with real project experience

- Verified validation workflows applied across multiple industries

- End-to-end support for your supply chain

Conclusion

CAE is not a replacement for physical testing—it is a powerful partner. By combining simulation with real-world experiments, companies can reduce costs, speed up development, and ensure reliable, safe products.

If you want to leverage the strengths of both CAE and physical testing to turn your designs into reality, TASVINA is here to support you. Contact us today for a free consultation!