Unlock Engineering Efficiency with CFD Analysis Services from TASVINA

In the modern era of product innovation and performance optimization, Computational Fluid Dynamics (CFD) analysis plays a critical role in driving engineering success. TASVINA, a trusted provider of CAE (Computer-Aided Engineering) services, offers advanced CFD simulation solutions to help companies across industries make informed, data-driven design decisions. From reducing prototyping costs to enhancing system performance, our CFD analysis services are engineered to deliver real-world results in a virtual environment.

What is CFD Analysis?

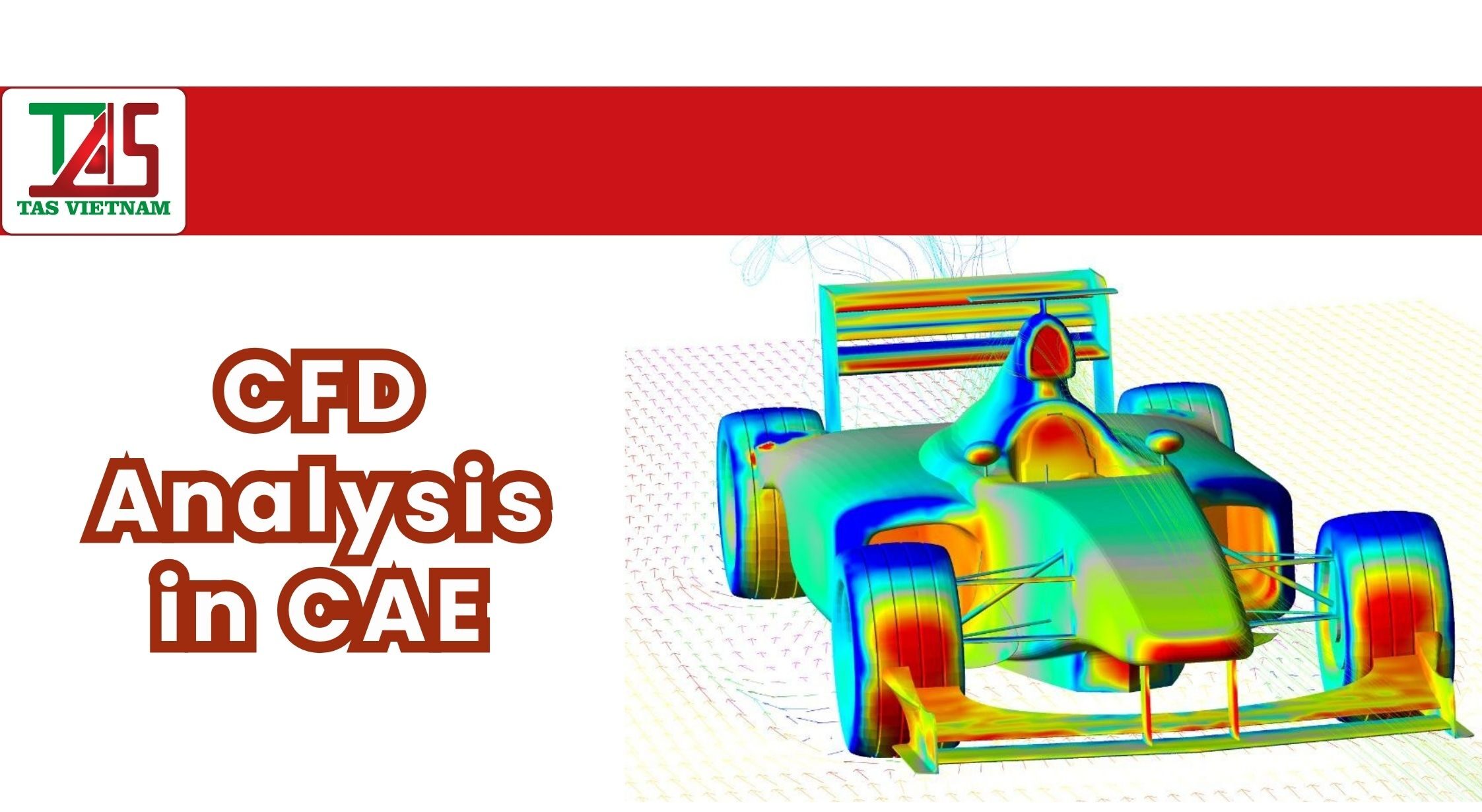

CFD (Computational Fluid Dynamics) analysis is a cutting-edge engineering method used to simulate the behavior of fluids—both liquids and gases—in a digital environment. By applying numerical methods and algorithms, CFD simulates the flow of fluids to calculate important variables such as pressure, velocity, and temperature throughout a given system. This type of analysis provides a visual and quantitative understanding of how fluids interact with surfaces, materials, and forces. Engineers can then use these insights to design more efficient products and systems without relying on time-consuming and costly physical testing.

How TASVINA Uses CFD Simulations to Add Value

At TASVINA, we harness the power of CFD simulations to help our clients optimize product performance, increase energy efficiency, and solve complex fluid dynamics problems. Our services provide accurate and detailed data to support better engineering decisions. Here’s what sets our CFD analysis apart:

1. Accurate Evaluation of Fluid Properties

We deliver precise simulation data that reveal how pressure, velocity, and temperature are distributed within your system. This enables engineers to identify potential performance issues, pressure drops, or thermal hotspots before physical prototypes are developed.

2. Optimization of Thermal and Ventilation Systems

Our CFD services are particularly effective in the design and refinement of thermal management systems, airflow paths, and cooling strategies. Whether you’re developing electronics with compact heat sources or improving the ventilation in HVAC systems, our CFD analysis allows for optimal heat dissipation and airflow control.

3. Prediction of Complex Fluid Behavior

TASVINA’s CFD simulations can model complex fluid behaviors in intricate components such as pipes, fans, radiators, and combustion chambers. We simulate real-world operational conditions to anticipate issues like turbulence, backflow, or inefficient mixing, which are often hard to detect in traditional testing methods.

4. Support for Multi-Industry Applications

CFD analysis is a versatile solution that serves a wide range of industries. TASVINA provides tailored CFD simulation services for sectors including:

- Automotive – Improve aerodynamics, engine cooling, and cabin ventilation.

- Electronics – Optimize heat sinks and internal airflow for better thermal performance.

- Energy – Enhance fluid transport in turbines, pipelines, and renewable systems.

- HVAC – Design efficient ventilation systems for residential, commercial, and industrial spaces.

- Consumer Products – Test product performance in terms of airflow, temperature control, and fluid movement.

Benefits of Choosing TASVINA for CFD Analysis

When you partner with TASVINA, you gain access to a team of experienced engineers and simulation experts who use industry-leading tools and methodologies. Here are a few key benefits of working with us:

- Cost-Efficient Development: Reduce the need for multiple physical prototypes by validating designs digitally.

- Shorter Time to Market: Accelerate design iterations with faster insights into system performance.

- Improved Product Quality: Identify performance issues early and enhance reliability through simulation.

- Custom-Tailored Solutions: We offer simulation strategies that are specifically aligned with your industry, product, and engineering goals.

Why CFD is Essential in Today’s Engineering Landscape

As product complexity increases, traditional trial-and-error testing methods are no longer sufficient. CFD provides a virtual test bed for engineers to experiment with different designs, materials, and conditions—ultimately leading to better products and lower development costs. Incorporating CFD analysis early in the product lifecycle allows you to design with confidence, minimize risks, and maximize efficiency. Whether you’re building next-gen electric vehicles, compact consumer electronics, or sustainable energy systems, TASVINA’s CFD services empower you to make better engineering decisions with less guesswork.

Partner with TASVINA for Expert CFD Simulation Services

With a commitment to technical excellence and customer satisfaction, TASVINA stands ready to support your CFD analysis needs. Our advanced simulation solutions help bridge the gap between concept and reality—delivering better performance, reduced costs, and smarter engineering outcomes.

Ready to optimize your designs with CFD?

Contact TASVINA today to learn how our fluid dynamics simulations can elevate your engineering process.