Precision CNC Programming Services for 3-Axis, 4-Axis, and 5-Axis Machining

At TASVINA, we provide high-precision CNC programming services tailored for 3-axis, 4-axis, and 5-axis machining. With deep expertise in Computer-Aided Manufacturing (CAM), our team turns your complex CAD models into production-ready G-code that drives efficiency, accuracy, and performance in every cut. Whether you’re in aerospace, mechanical engineering, or tool manufacturing, we help you achieve optimal results from your CNC machines.

What Is CNC Programming?

CNC (Computer Numerical Control) programming is a vital process in today’s advanced manufacturing workflow. It involves generating code that tells CNC machines exactly how to move and operate—defining tool paths, cutting strategies, and machining sequences to shape materials such as aluminum alloys, titanium alloys, and steel. Precision is essential, especially in industries where tolerances are tight and part quality is non-negotiable.

Our Expertise in Multi-Axis CNC Machining

At TASVINA, we specialize in multi-axis machining, enabling us to support a wide range of complex geometries and production requirements. Our CNC programming services include:

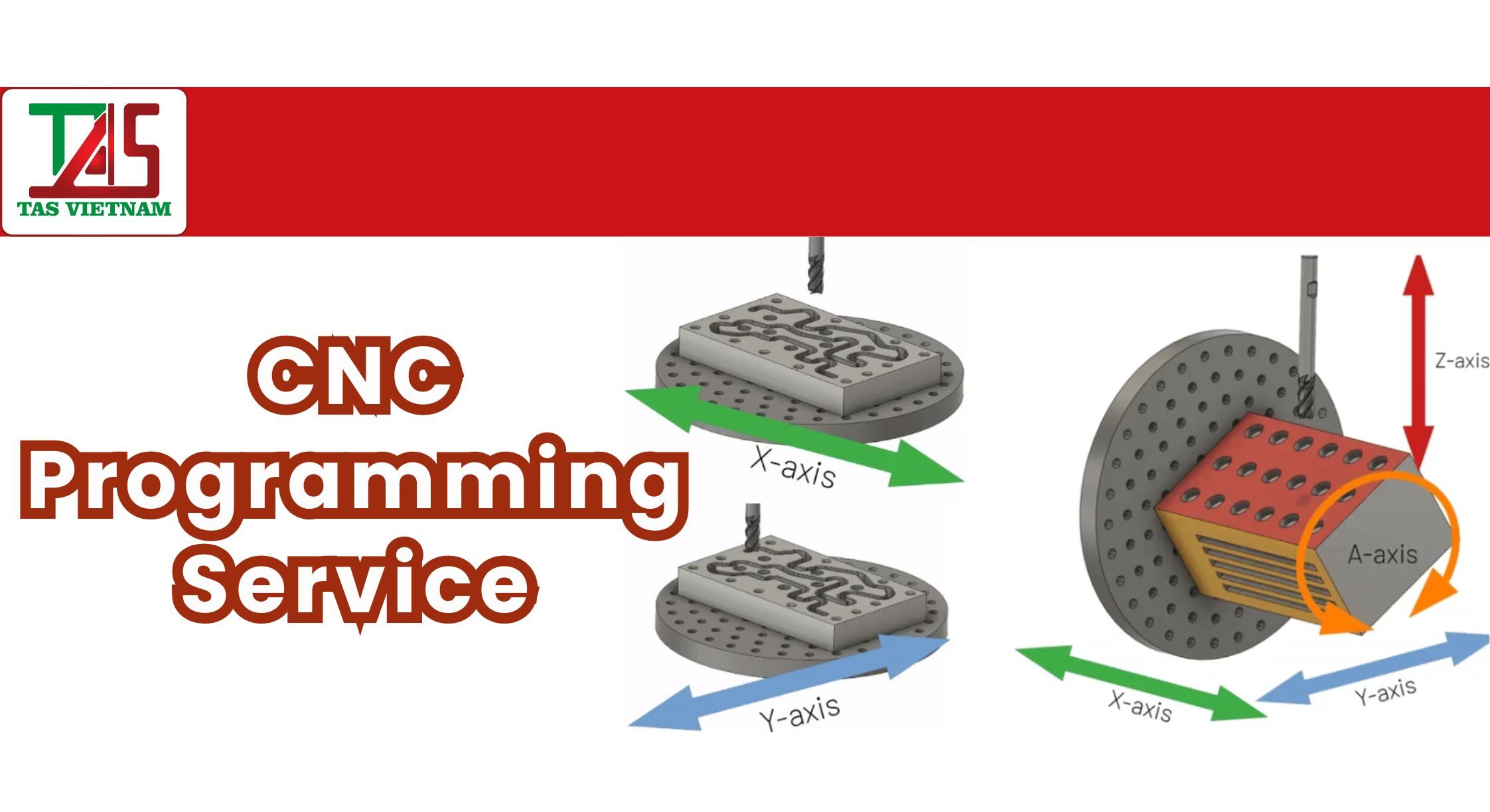

3-Axis Milling: Ideal for basic operations and machining flat surfaces.

4-Axis Machining: Adds a rotary axis, allowing for machining on different faces without repositioning the part.

5-Axis Machining: Offers simultaneous movement across all axes, perfect for intricate, high-precision parts with complex contours.

Multi-axis machining reduces the need for multiple setups, shortens production cycles, and significantly improves machining accuracy. This translates into higher productivity, reduced error rates, and improved product quality.

Advanced Software for Accurate Code Generation

To deliver cutting-edge results, we utilize industry-leading CAM software tools including:

CATIA V5-6 R2024: One of the most advanced platforms for CAD/CAM integration.

Vericut 9.5: A powerful verification tool that simulates and optimizes tool paths to prevent collisions and inefficiencies.

Our engineers use these tools to develop precise CNC programs that are compatible with various CNC machines, including milling centers, turning centers, and hybrid systems. We also offer post-processing customization to generate machine-specific G-code that works seamlessly with your existing equipment.

Our Comprehensive CNC Programming Services Include:

- Toolpath Strategy Development: We design optimal machining paths for faster, smoother, and more efficient production.

- Cutting Tool Selection & Optimization: We choose the best tools and parameters to enhance cutting performance and extend tool life.

- Post-Processing Configuration: We generate output tailored for your specific CNC machine brand and controller type.

- Code Optimization: Our programs aim to minimize cycle times, reduce tool wear, and eliminate unnecessary machine movements.

Why Choose TASVINA?

Partnering with TASVINA means working with a team that understands both the technical depth and practical demands of CNC manufacturing. We don’t just write code — we engineer solutions that optimize your production process.

Key Benefits of Our CNC Programming Services:

✅ Support for a wide range of industries, especially aerospace and precision engineering

✅ Seamless integration with leading CAM and CNC systems

✅ Fast turnaround times without compromising on accuracy

✅ Customized, machine-specific G-code for optimal performance

✅ Improved productivity through cycle time reduction and better tool usage

Industries We Serve

While our expertise spans multiple sectors, we have a strong focus on aerospace, where tight tolerances, high-strength materials, and complex geometries are standard requirements. We also serve clients in automotive, defense, industrial machinery, and medical device manufacturing.

Optimize Your CNC Production with TASVINA

If you’re looking to enhance your machining capabilities with reliable, accurate, and efficient CNC programming services, TASVINA is your trusted CAM partner. Contact us today to learn more about how we can help you streamline your production and increase part quality — all with precision you can trust.