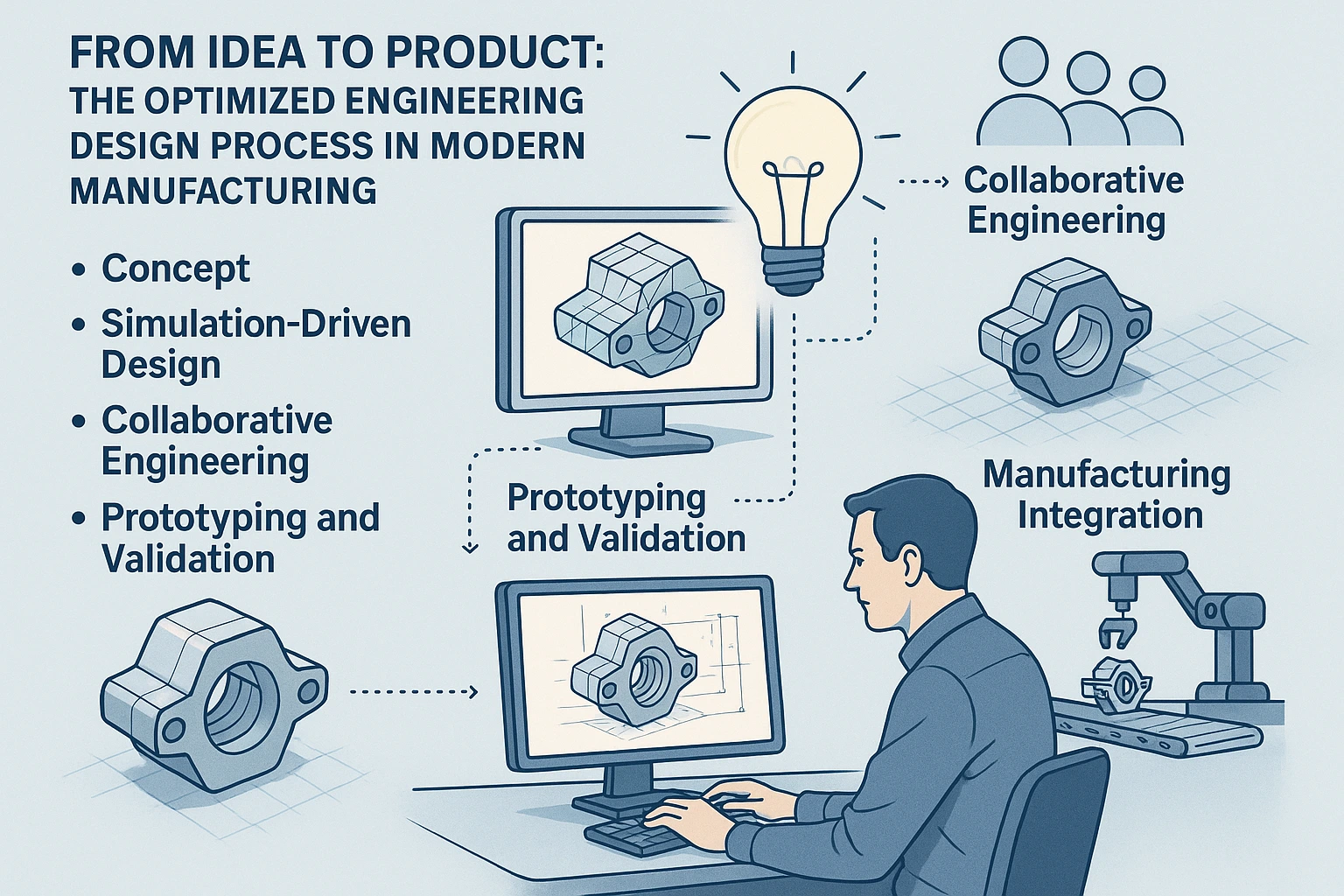

In today’s highly competitive manufacturing landscape, turning an idea into a tangible, high-quality product requires more than just creativity—it demands precision, collaboration, and cutting-edge engineering. The journey from concept to production has been revolutionized by digital transformation, simulation technologies, and integrated design workflows. Companies that master this process gain a significant advantage in time-to-market, cost efficiency, and innovation.

At TASVINA, we help businesses navigate this complex journey through advanced engineering design and simulation services, ensuring every stage of development is optimized for performance, quality, and manufacturability.

1. The Foundation: Transforming Ideas into Feasible Concepts

Every successful product begins with an idea—an innovation, a market need, or a vision for improvement. However, not every idea is ready for production. The first stage of the engineering design process focuses on concept validation.

Through early-stage feasibility studies and requirement analysis, engineers define the product’s purpose, key functionalities, and performance targets. This involves:

- Translating market or client requirements into technical specifications.

- Conducting preliminary sketches, digital mockups, or CAD models.

- Evaluating materials, cost implications, and manufacturability.

Digital engineering tools such as CATIA, NX, and SolidWorks allow design teams to visualize and iterate concepts rapidly, reducing the time between ideation and validation.

2. Simulation-Driven Design: The Power of Virtual Testing

Traditional product development relied heavily on physical prototypes—a costly and time-consuming process. Today, simulation technology enables engineers to test, analyze, and optimize designs virtually before a single part is manufactured.

This simulation-driven approach—powered by CAE tools such as ANSYS, Abaqus, or LS-Dyna—helps engineers predict product behavior under real-world conditions such as stress, heat, vibration, or fluid flow.

Key benefits of simulation-driven design include:

- Reduced prototyping costs and development time.

- Early detection of design flaws, minimizing rework.

- Performance optimization through iterative virtual testing.

At TASVINA, our engineering simulation experts use Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and Multibody Dynamics (MBD) to ensure products perform reliably in even the most demanding environments.

3. Collaborative Engineering: Integrating Design and Manufacturing

Modern manufacturing thrives on collaboration. The most efficient engineering processes integrate design, simulation, and production from the very beginning.

This concept—often referred to as Concurrent Engineering—ensures that designers, analysts, and manufacturers work together in real time. By aligning design intent with manufacturing capabilities, teams can prevent costly downstream errors and accelerate the production timeline.

Digital collaboration platforms such as PLM (Product Lifecycle Management) systems enable:

- Centralized data management and version control.

- Cross-functional collaboration between global teams.

- Seamless integration with ERP and manufacturing systems.

For multinational manufacturers operating in Vietnam, this approach is particularly valuable, as it bridges the gap between engineering centers abroad and local production facilities—ensuring quality consistency and process efficiency across borders.

4. Prototyping and Validation: From Digital to Physical

Once a design is optimized and validated virtually, the next step is physical prototyping and testing. Rapid prototyping technologies, such as 3D printing and CNC machining, have significantly shortened this stage.

Prototypes allow engineers to:

- Verify ergonomics, aesthetics, and assembly.

- Conduct functional and durability tests.

- Gather user feedback for further refinement.

By combining virtual validation with physical testing, companies can achieve a robust and reliable design faster than ever before.

5. Manufacturing Integration: Design for Production

A brilliant design is only as good as its manufacturability. That’s why the final phase focuses on Design for Manufacturing (DFM) and Design for Assembly (DFA) principles.

These practices ensure that each component can be produced efficiently without compromising quality. Engineers analyze aspects such as:

- Material selection and tolerances.

- Tooling and fixture requirements.

- Assembly complexity and automation readiness.

With simulation-based manufacturing solutions—such as digital twins and process optimization tools—companies can fine-tune production systems even before launching mass production.

6. Continuous Improvement Through Digital Engineering

The design process does not end once a product reaches the market. In modern manufacturing, data-driven improvement is continuous.

Through digital feedback loops, performance data from real products can be fed back into the design phase. This closed-loop system enables predictive maintenance, performance enhancements, and faster innovation cycles.

As industries move toward Industry 4.0, the integration of IoT, AI, and data analytics allows companies to make smarter design and manufacturing decisions, reducing waste and maximizing efficiency.

Conclusion: Engineering the Future of Manufacturing

From concept development to production launch, the engineering design process has evolved into a data-driven, collaborative, and simulation-based ecosystem. Companies that embrace this digital approach gain not only faster development cycles but also higher-quality products and improved competitiveness in global markets.

At TASVINA, we empower businesses—especially international manufacturers operating in Vietnam—to achieve these goals. Through our expertise in engineering design, digital simulation, and technical consulting, we help clients transform innovative ideas into optimized, manufacturable, and market-ready products.