Kinematic Simulation (DMU Check) Service – Optimize Your CAD Design with TASVINA

In the field of product design and engineering, ensuring that components interact flawlessly is crucial to creating high-quality, reliable products. At TASVINA, we offer professional Kinematic Simulation (DMU Check) services to help you identify and eliminate potential mechanical issues during the early stages of product development.

Our service focuses on checking the motion between parts in your CAD models, ensuring no collisions or mechanical faults occur during assembly or operation. Through detailed dynamic simulations, we help you catch design errors early, saving you from costly modifications later in the development process.

What is Kinematic Simulation (DMU Check)?

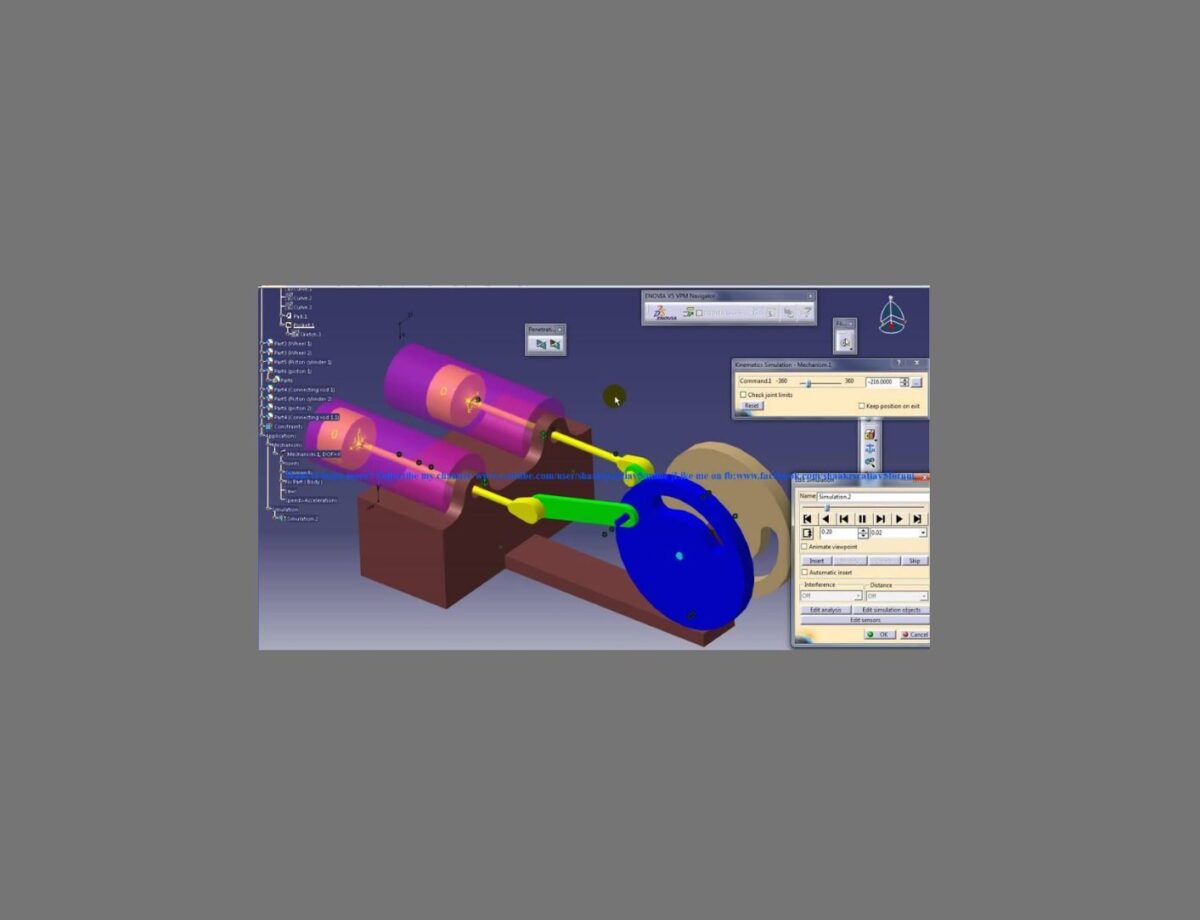

Kinematic Simulation, also known as DMU (Digital Mock-Up) Check, involves virtually simulating the movement of parts within an assembly. By setting up and testing the motion process, we can visualize and analyze how different components move relative to each other. The goal is to ensure that there are no unexpected collisions, interferences, or mechanical malfunctions during actual operation.

At TASVINA, we perform a full kinematic setup and simulation, including:

- Setting up motion processes: We define how components should move within the system, establishing realistic motion paths based on your design intentions.

- Collision checking: We thoroughly test the movement of parts to detect any potential collisions or clashes that could cause failure or inefficiency.

- Determining locus and safe operating areas: We analyze and optimize the range of motion for each component, ensuring smooth operations within safe limits.

This comprehensive simulation process gives you confidence that your product will function exactly as intended before it even reaches the prototype stage.

Why Choose TASVINA’s Kinematic Simulation Service?

- Early Error Detection: By identifying issues at the CAD stage, you can avoid costly redesigns and delays later in the production cycle.

- Improved Design Quality: Our simulations help ensure your products meet the highest standards of safety, reliability, and performance.

- Cost Savings: Catching and correcting errors early significantly reduces the need for physical prototypes and expensive modifications.

- Faster Time-to-Market: With fewer setbacks and revisions, your product development process becomes more efficient, helping you launch faster.

- Expert Support: Our experienced engineering team understands complex mechanical systems and utilizes advanced CAD tools to deliver precise and reliable simulation results.

Our Kinematic Simulation Process

At TASVINA, we follow a systematic process to deliver accurate DMU check results:

- CAD Model Review: We start by carefully examining your CAD models to understand the assembly structure and mechanical functions.

- Motion Setup: We define movement constraints and degrees of freedom for each part based on your functional requirements.

- Dynamic Simulation: We simulate real-world motion scenarios, observing how components interact under various conditions.

- Collision Analysis: We conduct detailed collision detection to pinpoint any areas where parts may interfere.

- Reporting and Recommendations: We provide comprehensive reports outlining any detected issues along with expert recommendations for design improvements.

Applications of Kinematic Simulation

Kinematic Simulation is essential across many industries, including:

- Automotive: Ensuring proper movement of doors, seats, and mechanical linkages.

- Aerospace: Checking moving parts such as landing gears, control surfaces, and cabin mechanisms.

- Industrial Equipment: Verifying safe and efficient movement in machinery and robotic systems.

- Consumer Products: Validating mechanisms in appliances, electronics, and tools.

No matter your industry, ensuring smooth and collision-free motion between components is vital to achieving a successful product.

Partner with TASVINA for Reliable Kinematic Simulation

Investing in a Kinematic Simulation (DMU Check) with TASVINA means you are taking a proactive step towards creating superior designs with minimal risk. Let our team help you validate your product’s dynamic performance and bring your ideas to life with precision and confidence.

Contact us today to learn more about how our kinematic simulation services can optimize your design process and ensure a seamless path to production!