Description

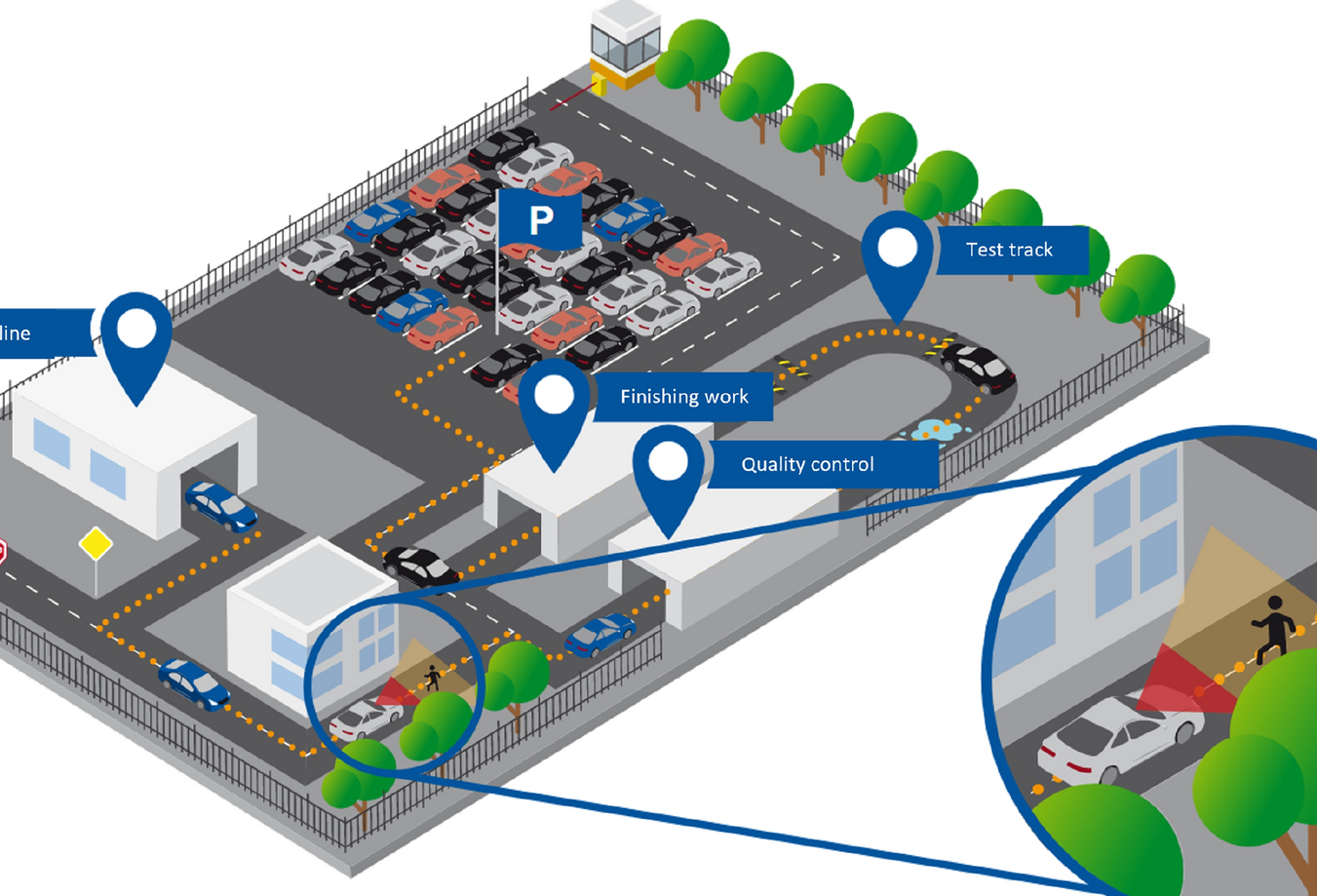

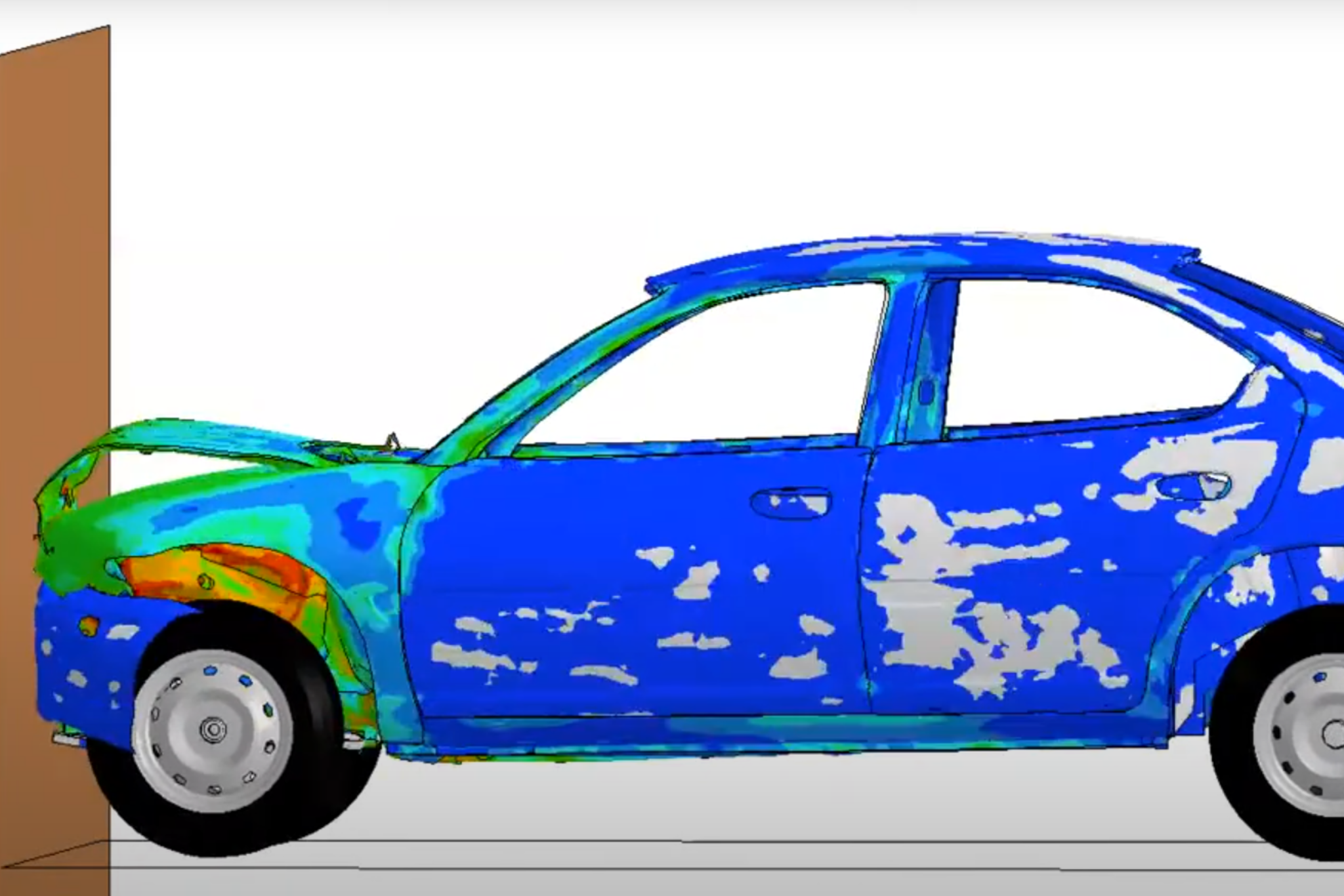

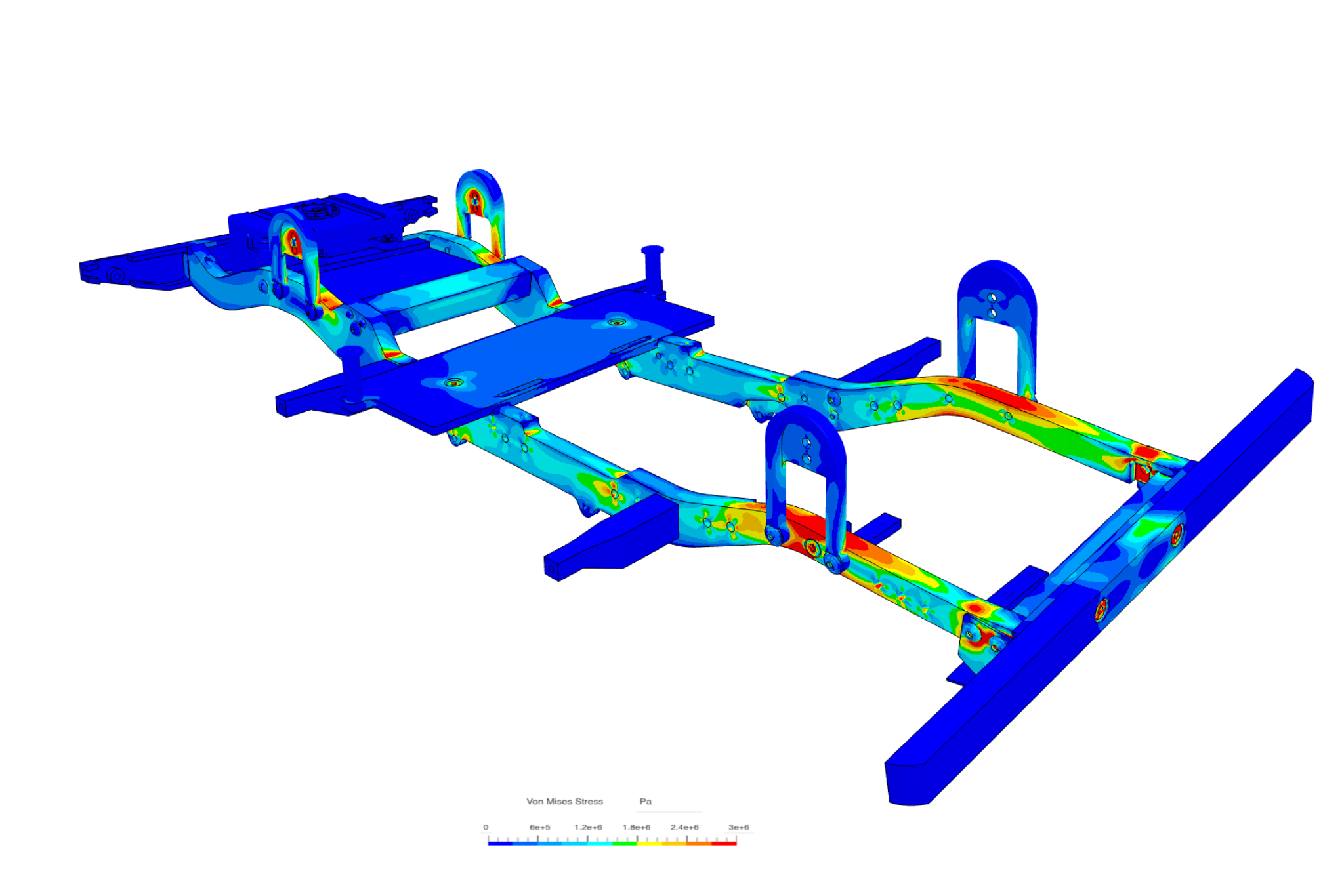

TASVINA offers Full Vehicle Virtual Assembly services to simulate the entire vehicle assembly process in a 3D virtual environment. This solution enables early detection of design conflicts, assembly feasibility issues, and spatial interferences. By validating designs virtually, manufacturers can reduce physical prototyping costs, shorten development time, and improve production efficiency.

Key Benefits:

- Evaluate assembly feasibility and serviceability of components

- Verify overall design accuracy and integration

- Optimize manufacturing processes before physical build

- Detect clashes and interferences between systems

Reviews

There are no reviews yet.