Description

|

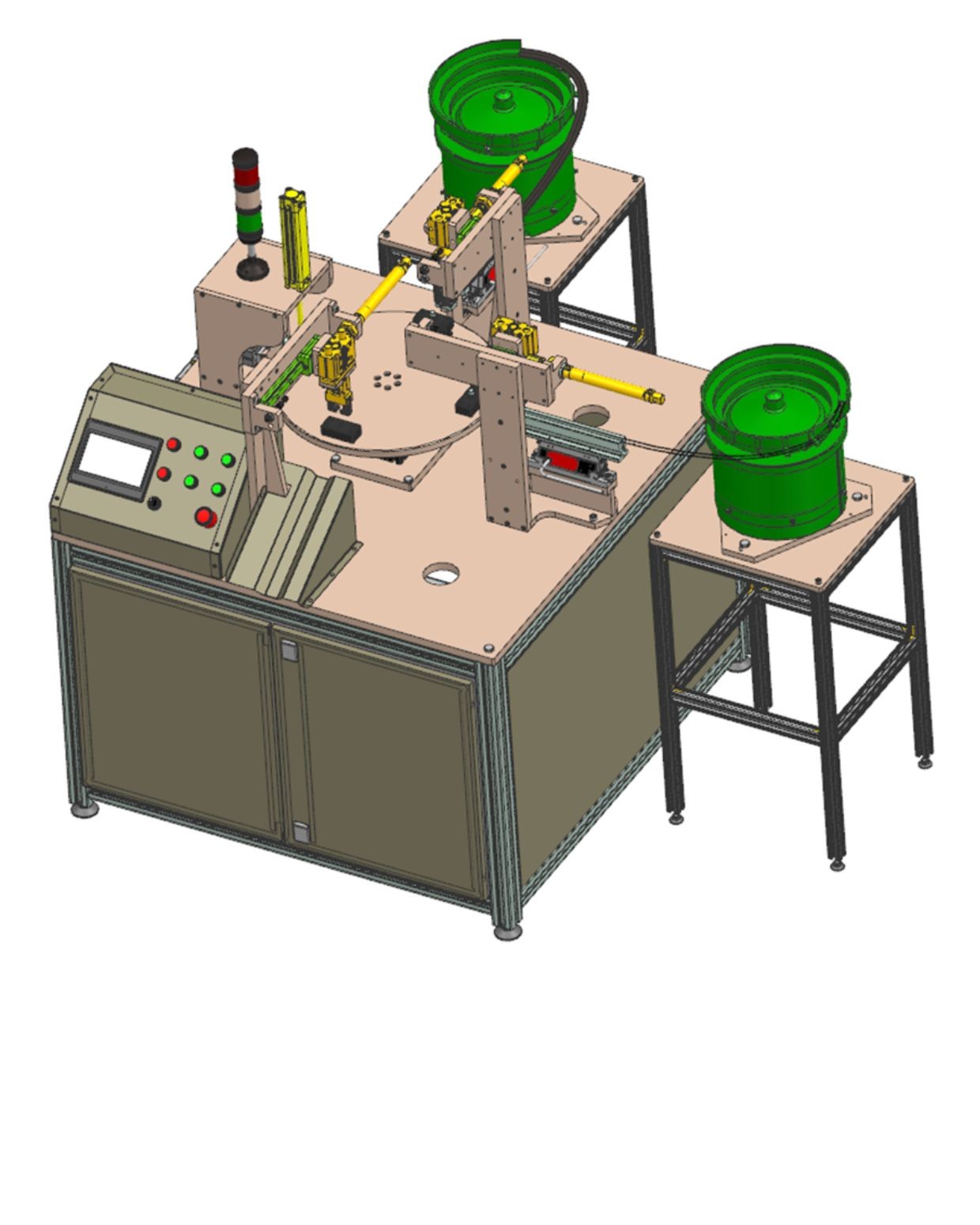

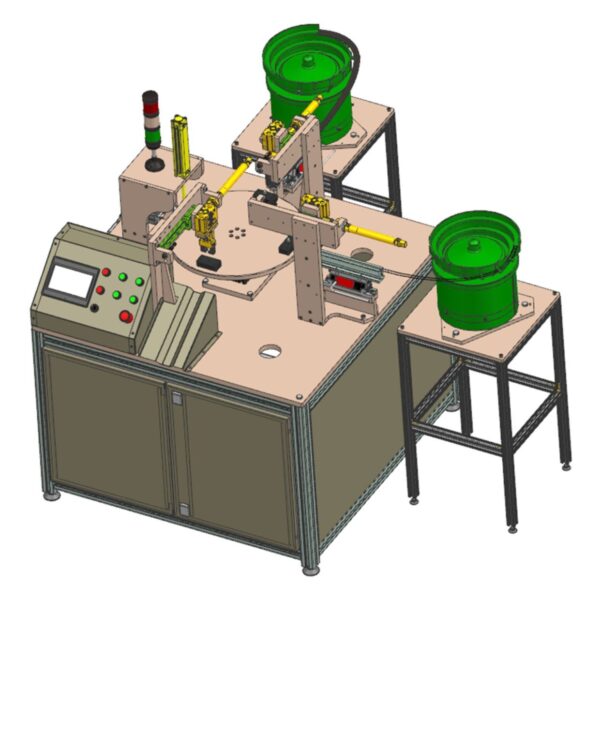

Item |

Specification |

|

Function |

Automatically assemble O-rings onto cylindrical shafts or components |

|

Machine Structure |

Aluminum profile frame with steel and aluminum modules, powder-coated panels |

|

Feeding System |

2 vibratory bowl feeders (one for O-rings, one for shaft parts) |

|

O-Ring Size Range |

Ø10 – Ø60 mm (customizable) |

|

Part Type |

Cylindrical shafts, plugs, or pistons (custom dimensions) |

|

Assembly Method |

Pneumatic stretching and pushing into groove or surface |

|

Indexing System |

Rotary indexing table (4–6 positions) with precision rotation motor |

|

Actuators |

Pneumatic cylinders (Festo/SMC or equivalent) |

|

Cycle Time |

~4–6 seconds per assembly (depending on part size and stretch complexity) |

|

Output Capacity |

~600–900 pcs/hour |

|

Control System |

PLC (Siemens/Mitsubishi/Omron) + 7” HMI touchscreen |

|

Sensors |

Photoelectric sensors, fiber sensors for part detection and position confirmation |

|

Air Supply |

0.5 – 0.6 MPa (dry and clean compressed air) |

|

Power Supply |

220V AC – 50Hz |

|

Safety Features |

Emergency stop, safety door interlock, signal tower light |

|

Applications |

Automotive, medical, industrial sealing components |

Reviews

There are no reviews yet.