Mold Design Services at TASVINA: Optimizing Production with CAD Technology

At Tasvina, we specialize in Mold Design, providing cutting-edge solutions for the creation of both plastic molds and metal casting molds. Our services are tailored to industries that require precision and high-efficiency production, including electronics, consumer goods, automotive, and medical sectors. With a focus on accuracy, material optimization, and enhanced production capabilities, we deliver molds that meet the highest industry standards.

What is Mold Design?

Mold design refers to the process of creating a mold that will be used in the production of parts or components through various manufacturing techniques, such as injection molding, casting, or stamping. These molds are critical in industries that require mass production of parts with uniform quality and precision. Mold design ensures that the final product is produced accurately and efficiently while minimizing material waste and reducing production costs.

Types of Molds We Design at Tasvina

At Tasvina, we provide a comprehensive range of mold design services, including:

- Plastic Injection Molds:

- These molds are used for shaping plastic materials through injection molding processes. They are widely used in industries such as consumer goods, electronics, and medical devices due to their versatility and cost-effectiveness.

- Metal Casting Molds (Pressure Casting Mold):

- Our pressure casting molds are ideal for producing metal parts with high precision and durability. They are commonly used in industries like automotive and aerospace, where strength and accuracy are paramount.

- Sheet Metal Stamping Molds:

- These molds are used in the stamping process to produce metal parts through compression, bending, or cutting. They are integral to automotive, electronics, and industrial applications where metal components are required in high volumes.

- Pressing Molds:

- Pressing molds are essential for manufacturing products through pressing techniques, typically in the automotive and consumer electronics industries.

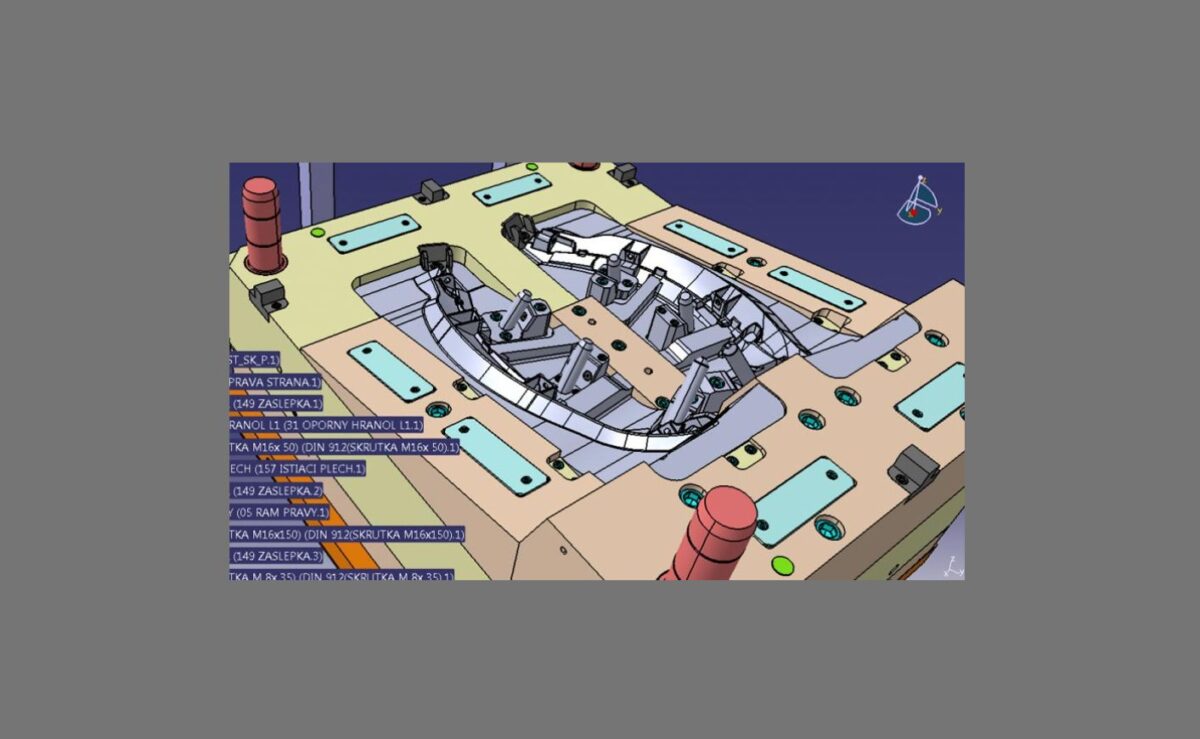

Integration of CAD, CAE, and CAM in Mold Design

One of the key aspects that set Tasvina’s mold design service apart is our integration of CAD (Computer-Aided Design), CAE (Computer-Aided Engineering), and CAM (Computer-Aided Manufacturing) into the mold design process. This advanced technological approach enhances every phase of mold development:

- CAD: Our designers use state-of-the-art CAD software to create detailed and precise 3D models of the molds. These models allow for a clear visual representation of the final product and provide a solid foundation for simulation and analysis.

- CAE: Using CAE tools, we perform simulations to assess the performance of the mold before production. This step helps identify potential issues, such as material flow problems or structural weaknesses, allowing us to optimize the design for better efficiency and performance.

- CAM: By incorporating CAM, we ensure that the mold designs are seamlessly translated into the manufacturing process. This integration reduces the chances of errors during production and accelerates the time from design to manufacturing.

Benefits of Mold Design at Tasvina

- High Precision and Accuracy: Our advanced CAD, CAE, and CAM technologies ensure that every mold we design meets the highest standards of precision, resulting in consistent, high-quality products.

- Material Optimization: We focus on optimizing material usage, ensuring that the right amount of material is used to create each mold. This reduces waste and lowers production costs, making the entire manufacturing process more sustainable.

- Faster Time to Market: Through the integration of these technologies, we streamline the mold design process, enabling faster prototyping and testing. This reduces the time it takes to bring your product to market, helping you stay competitive in fast-paced industries.

- Cost-Effective Solutions: By leveraging our deep expertise and advanced technologies, we can reduce the overall cost of production. Our designs help minimize the need for expensive rework, repairs, and material waste.

- Customization and Flexibility: We understand that each project is unique. Whether you are looking for plastic molds for consumer products, metal molds for automotive parts, or specialized molds for medical devices, Tasvina offers tailored solutions to meet your specific requirements.

Industries We Serve

Our mold design services cater to a wide range of industries, including:

- Electronics: Molds for consumer electronics, connectors, and enclosures.

- Consumer Goods: Molds for packaging, household items, and personal care products.

- Automotive: Molds for interior and exterior parts, including dashboard components, bumpers, and more.

- Medical: Molds for high-precision medical devices, including surgical tools and diagnostic equipment.

Conclusion

At Tasvina, we are committed to delivering mold design solutions that are efficient, cost-effective, and tailored to your specific production needs. By integrating CAD, CAE, and CAM technologies, we ensure that your molds are designed to the highest standards, optimizing the entire manufacturing process. Whether you’re in the electronics, automotive, or medical industry, Tasvina has the expertise to provide you with molds that drive quality and efficiency in your production.

Contact us today to learn how our mold design services can help optimize your manufacturing process and reduce costs.