Description

Objective:

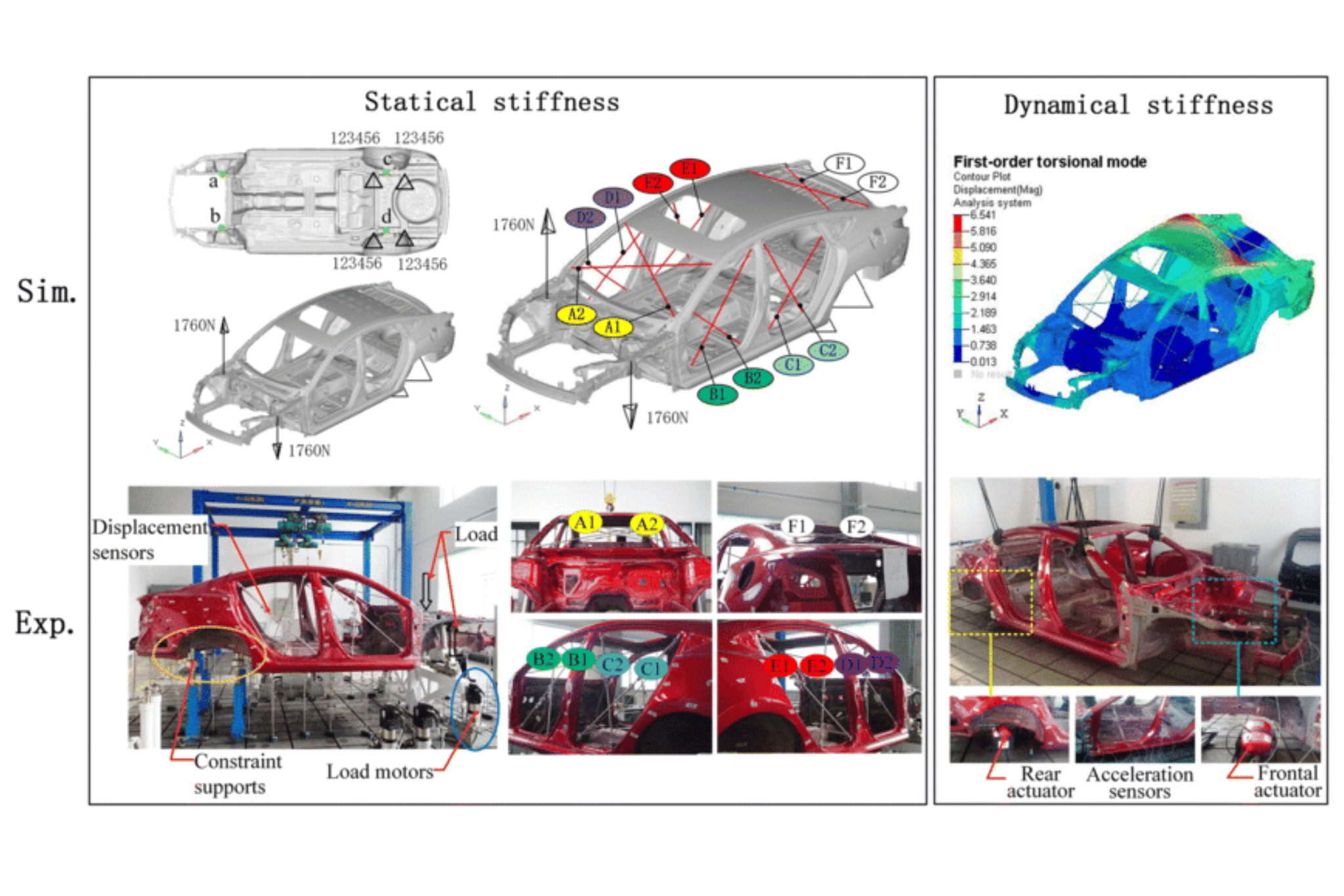

- Evaluate the load-bearing capacity of the vehicle body under static and dynamic impacts.

- Determine the stiffness of the components making up the vehicle body and their interactions.

- Predict the deformation and stress of the vehicle body under various load conditions.

- Improve the vehicle’s dynamic performance and safety by optimizing the stiffness of the vehicle body.

Requirements:

- Modeling the Vehicle Body: Use simulation software such as ANSYS, Abaqus, or LS-DYNA to create a detailed 3D model of the vehicle body.

- Material Identification and Properties: Provide detailed information about the materials of the vehicle body components, including Young’s modulus, Poisson’s ratio, and yield strength.

- Applying Loads: Identify the static and dynamic loads the vehicle body will endure, such as impact forces, gravitational loads, and wind loads.

- Result Analysis: Interpret the simulation results, including the deformation, stress, and stiffness of the vehicle body.

- Comparison with Experimental Results: Conduct experimental tests to validate the accuracy of the simulations.

Results:

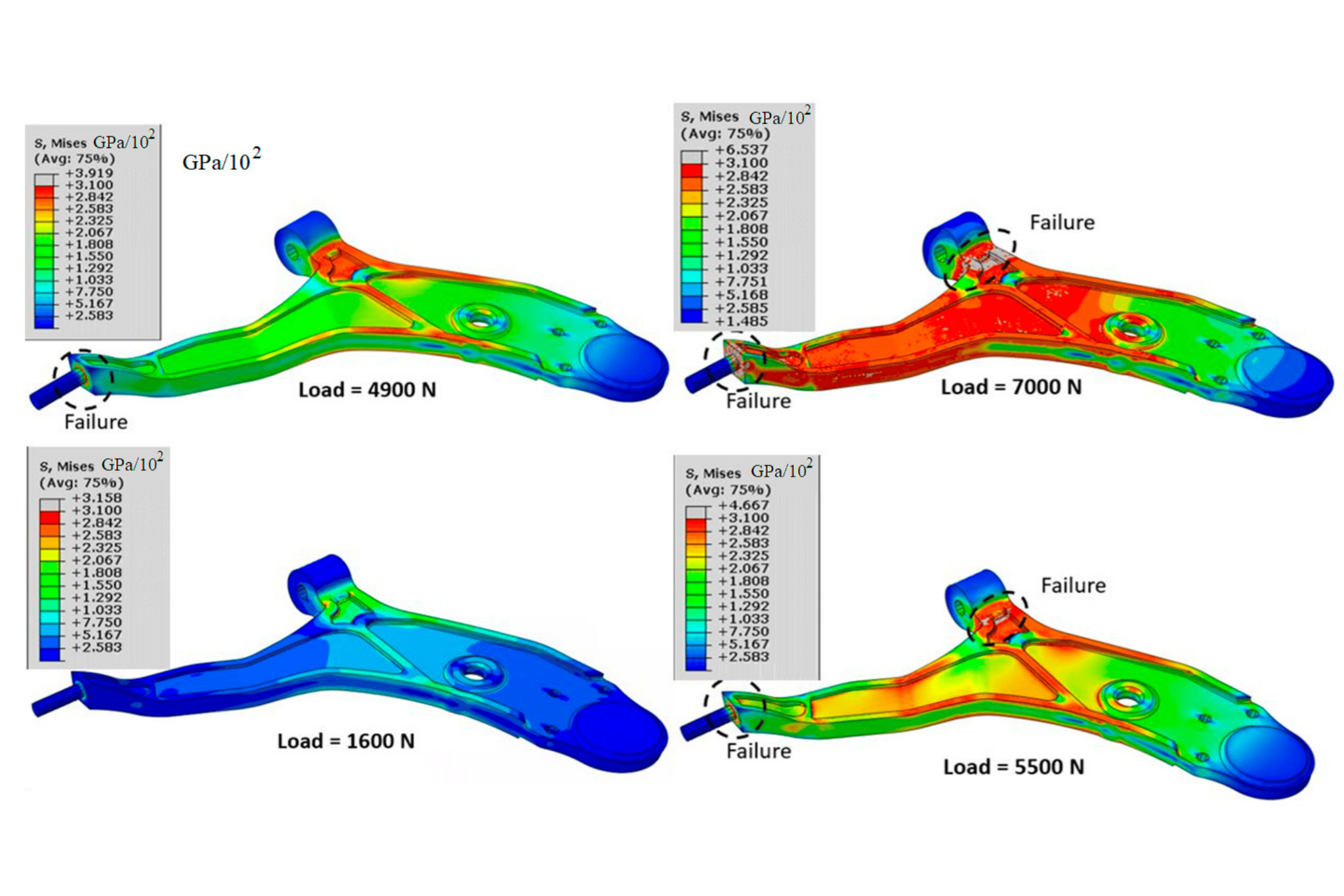

- Deformation and stress maps of the vehicle body under different load conditions.

- Values of the static and dynamic stiffness of the vehicle body and its components.

- Analysis of weak points and high-risk areas in the vehicle body design.

- Design improvement suggestions to enhance the stiffness and performance of the vehicle body.

Applications:

- Vehicle Body Design: Use simulation and experimental results to optimize the vehicle body design, ensuring maximum stiffness and performance.

- Crash Analysis: Predict the level of damage to the vehicle body in case of collisions and improve the vehicle’s safety performance.

- New Material Development: Evaluate the effectiveness of new materials in enhancing the stiffness and performance of the vehicle body.

- Quality Control: Use simulations and experiments to check the quality of the vehicle body and detect potential defects.

Reviews

There are no reviews yet.