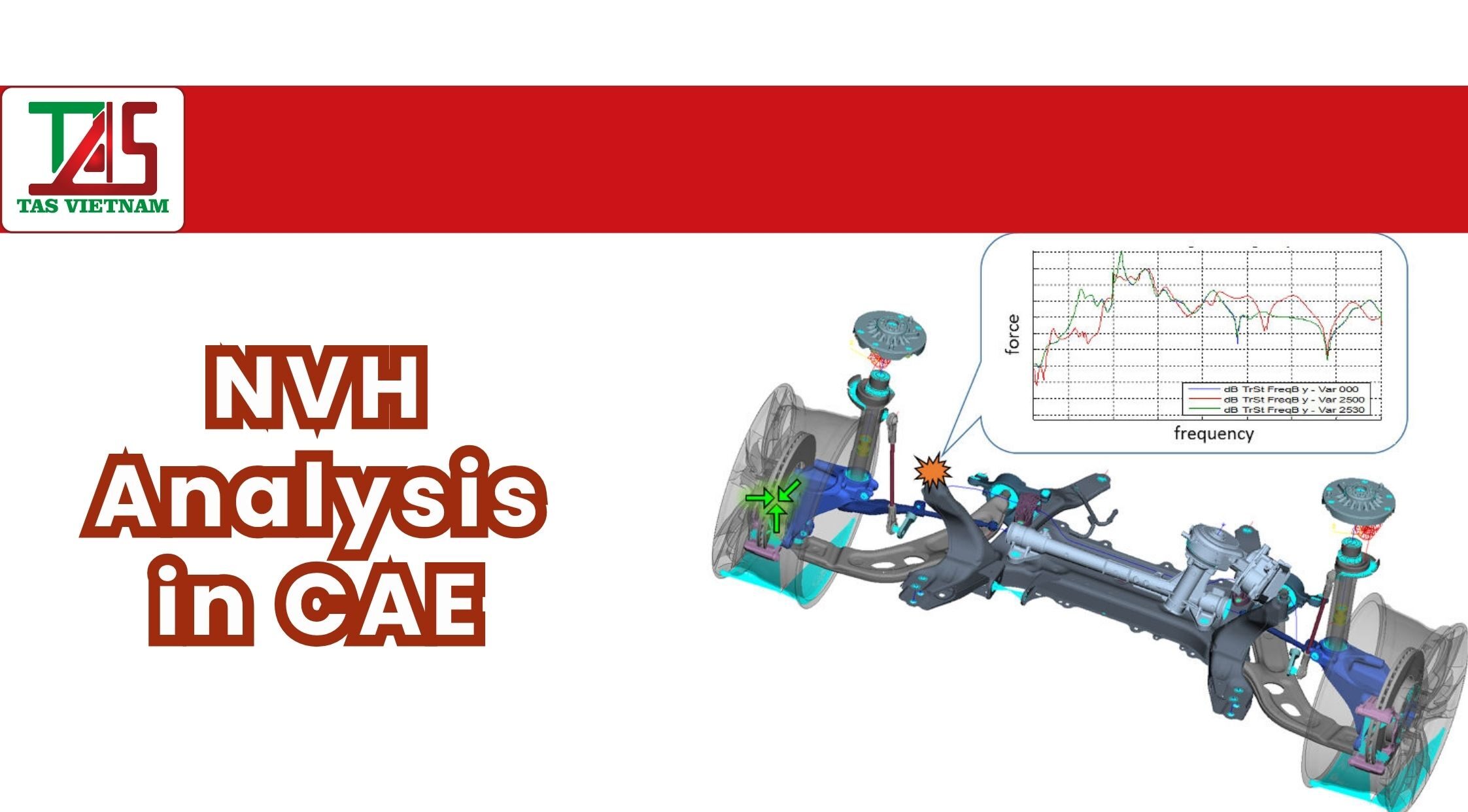

Enhancing Product Quality with Advanced NVH Analysis Services from TASVINA

In today’s competitive market, user experience and product performance go hand-in-hand. One critical factor affecting both is NVH – Noise, Vibration, and Harshness. At TASVINA, we specialize in NVH analysis using state-of-the-art CAE (Computer-Aided Engineering) techniques to help manufacturers design quieter, smoother, and more comfortable products. Our simulations go beyond standard testing methods by evaluating complex material behaviors including viscoelasticity, nonlinearity, and hyperelasticity.

What Is NVH Analysis?

NVH analysis refers to the study of noise, vibration, and harshness in mechanical systems. It helps engineers understand how vibrations and sounds are generated, transmitted, and perceived by users. This process is crucial in improving acoustic comfort, product durability, and user satisfaction—especially in industries like automotive, consumer electronics, and electromechanical systems.

TASVINA’s NVH analysis services use CAE simulation to model how materials behave under real-world operating conditions. By doing so, we enable clients to optimize their designs during the early stages of product development, significantly reducing costs and time-to-market.

Why Advanced Material Simulation Matters

Conventional NVH analysis often assumes materials are linear and ideal. However, in real-life applications, materials behave differently under varying temperatures, loads, and frequencies. TASVINA addresses this challenge by offering specialized simulations for:

1. Viscoelastic Materials

Viscoelastic materials exhibit both viscous and elastic characteristics when deformed. They play a vital role in damping vibrations and reducing noise, especially in automotive interiors, engine mounts, and speaker systems. Our simulations model how these materials respond over time, including creep, stress relaxation, and hysteresis effects, to accurately predict performance under dynamic conditions.

2. Nonlinear Materials

Nonlinear materials do not follow a simple stress-strain relationship. Their behavior can change depending on the amount and type of load applied. Components made from such materials can behave unpredictably if not analyzed correctly. TASVINA’s nonlinear material modeling helps identify critical thresholds and failure points, ensuring your product performs reliably throughout its lifecycle.

3. Hyperelastic Materials

Hyperelastic materials are often used in applications where high flexibility and deformation are required—such as rubber seals, gaskets, and soft electronics. Unlike standard materials, they can undergo large strains and still return to their original shape. Our hyperelastic material analysis ensures that such components maintain their shape and function under repeated use, pressure, and environmental stress.

Applications Across Industries

TASVINA’s NVH analysis capabilities are ideal for a variety of sectors:

- Automotive Interiors: Improve cabin comfort by identifying and eliminating vibration and noise sources from dashboards, doors, and seats.

- Consumer Electronics: Reduce buzzing and rattling in smartphones, laptops, and other portable devices.

- Electromechanical Systems: Optimize performance and durability of components such as motors, compressors, and actuators.

Benefits of TASVINA’s NVH Analysis

- Improved Acoustic Comfort: Eliminate unwanted noise and vibrations that negatively impact the user experience.

- Enhanced Product Smoothness: Identify and mitigate sources of harshness to improve perceived product quality.

- Material Behavior Insights: Make informed material selections based on accurate, simulation-driven performance data.

- Early Problem Detection: Solve issues during the design stage, minimizing costly redesigns later.

- Shorter Development Cycles: Accelerate time-to-market with efficient, predictive simulations.

Why Choose TASVINA?

At TASVINA, we combine engineering expertise, advanced simulation tools, and a deep understanding of material science to deliver comprehensive NVH solutions tailored to your product and industry. Our focus on viscoelastic, nonlinear, and hyperelastic materials ensures precision and realism in every analysis. We work closely with your team to understand your needs, analyze your components, and deliver actionable insights that drive better design decisions.

Contact TASVINA Today

Want to reduce noise and vibration in your next product? Let our experts at TASVINA help you create smoother, quieter, and more reliable systems with our cutting-edge NVH analysis services.