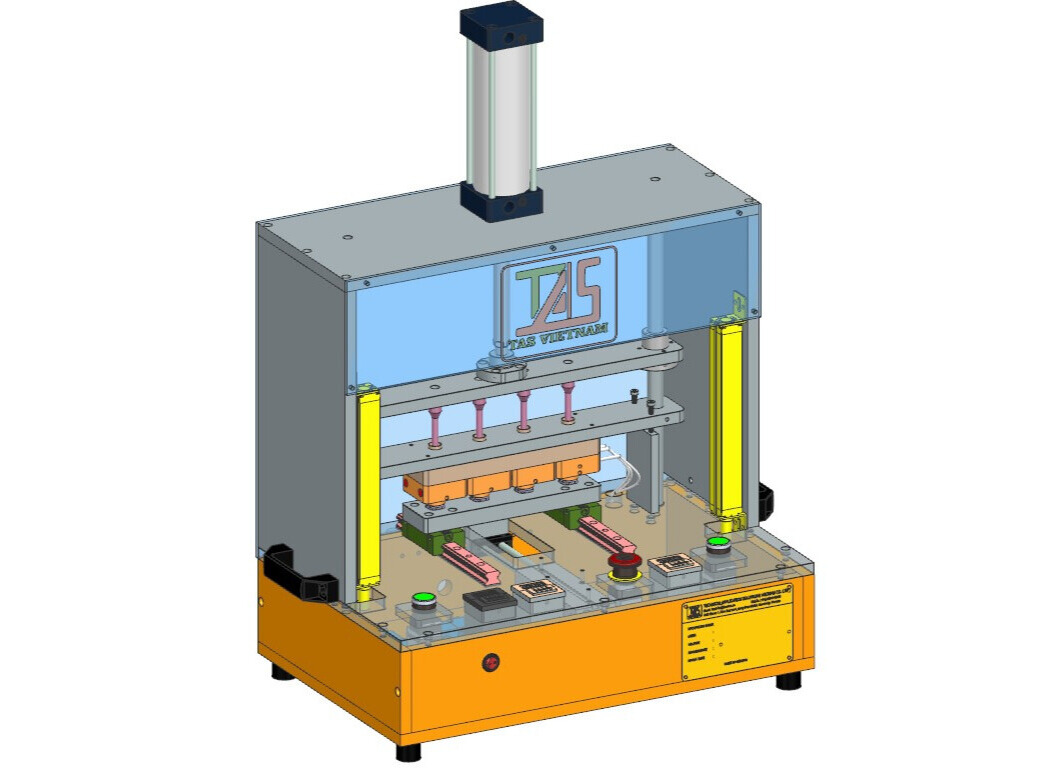

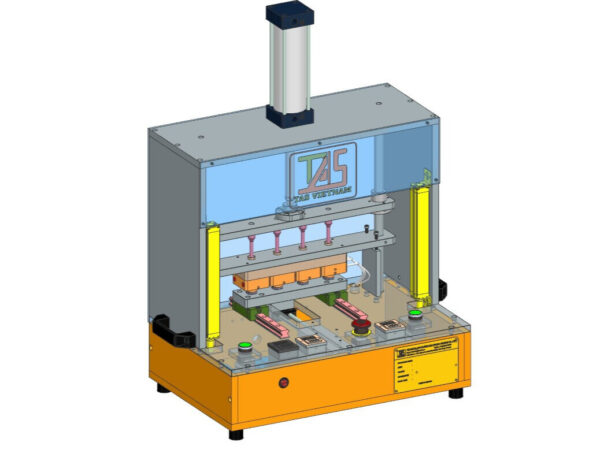

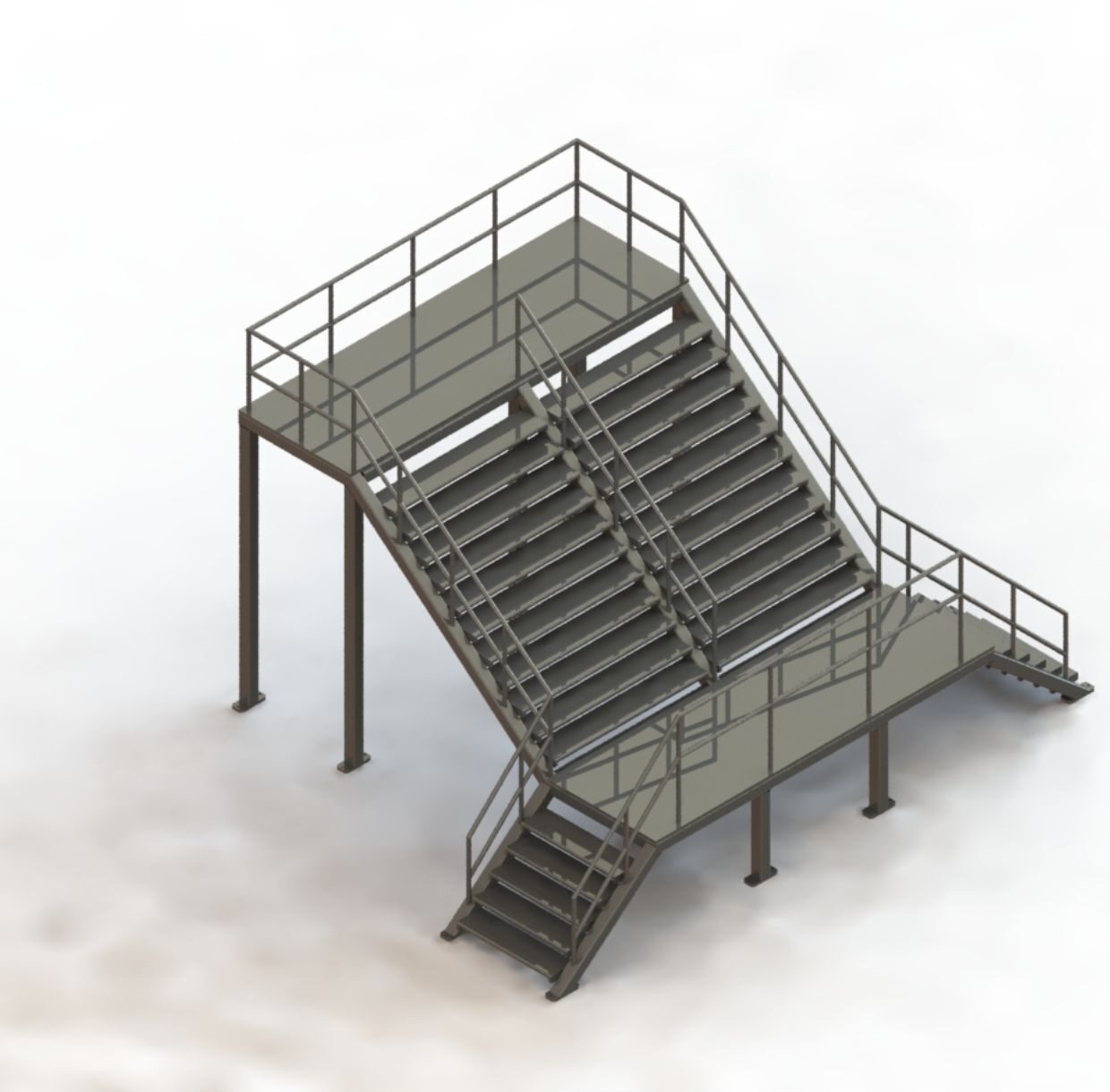

Description

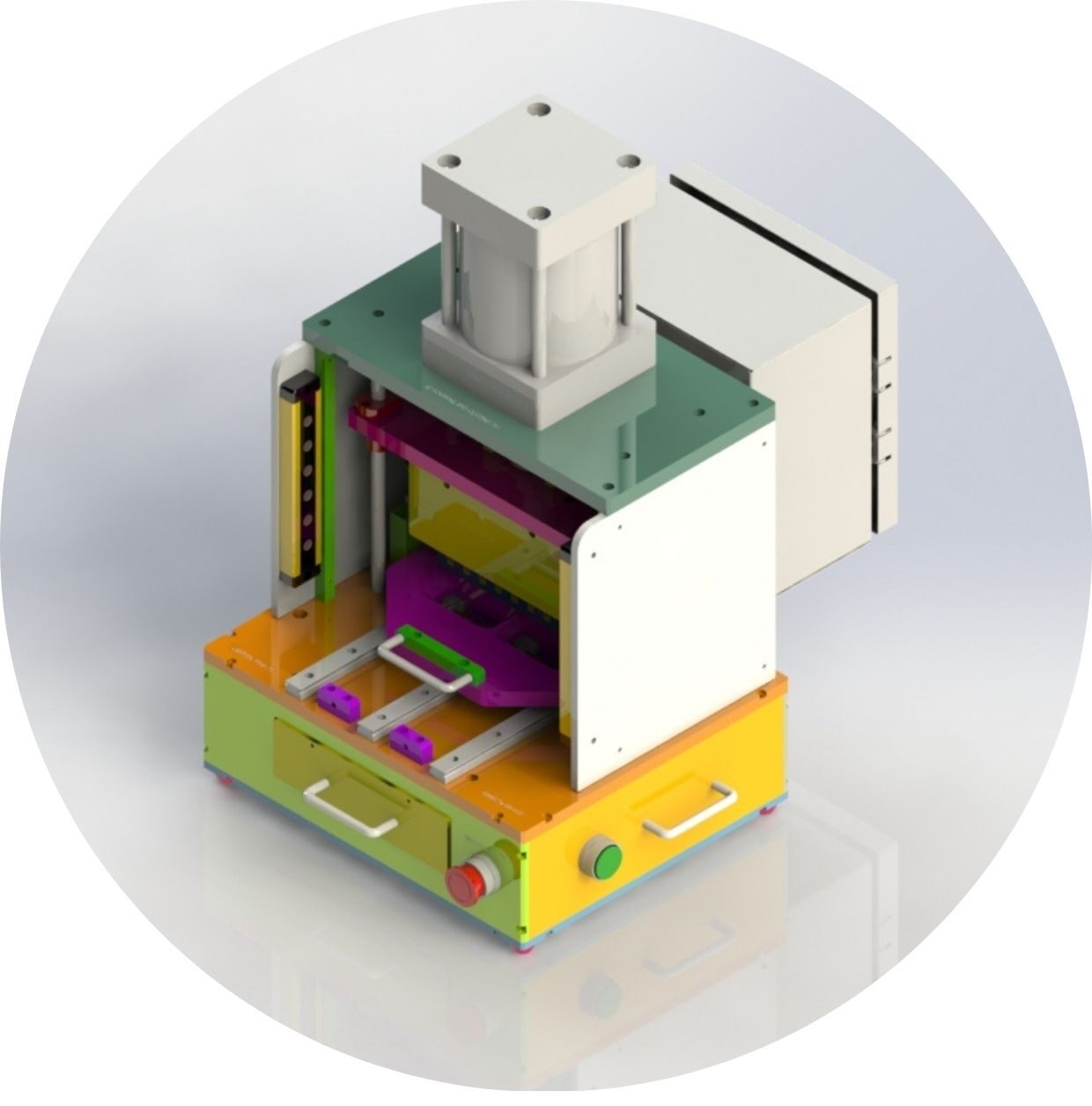

Assembly JIG is a device or tool used to fix and position parts of a product during the assembly process, ensuring accuracy and efficiency. In industrial manufacturing, it is a crucial part of mass production, helping to minimize errors and increase productivity.

- Popular types of assembly jigs include:

1. Fixed JIG: Holds parts securely in place so workers can perform other operations.

2. Guiding JIG: Directs or guides other tools, such as drills or milling cutters, ensuring accurate positioning when operating on parts.

3. Adjustable JIG: Allows for adjustments to parts to achieve precise size and shape requirements.

4. Clamping JIG: Holds parts tightly to prevent movement.

5. Automation JIG: Integrated with automation equipment such as robots to perform assembly tasks with minimal human intervention.

Using an assembly JIG can reduce assembly time, improve product quality, and ensure parts are assembled precisely according to the design.

Contact: Nguyen Xuan Canh (Mr. Orion) (Sales Manager) Phone: (+84) 905.648.436 Email: tas.info@tasvina.com

Reviews

There are no reviews yet.