Introduction

In the era of Industry 4.0, automation is no longer a luxury reserved for large factories — it has become a crucial factor that determines whether a manufacturing business can stay competitive. Yet, for many enterprises in Vietnam, “automation” still sounds expensive, complex, and difficult to implement.

At TASVINA, we believe that smart automation should start gradually and strategically — combining human expertise with the right level of technology to achieve sustainable efficiency.

1. What Is Smart Automation?

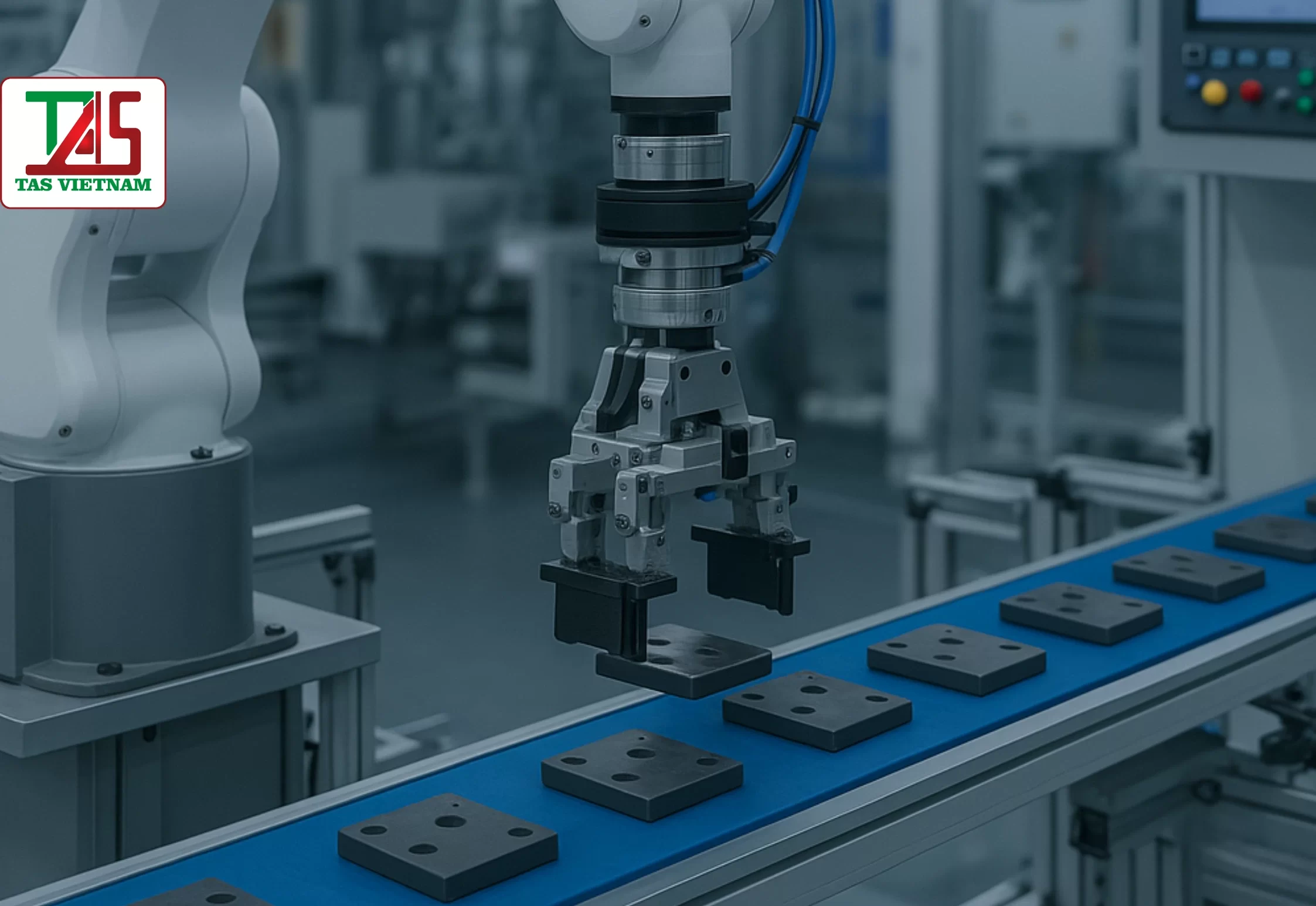

Unlike traditional automation systems that focus solely on replacing manual tasks, smart automation is a holistic approach that integrates mechanical design, control systems, sensors, and data analytics to create flexible and intelligent production lines.

A “smart” automated line doesn’t just move parts — it learns, adjusts, and communicates. For example, a robotic arm connected to a PLC system can automatically adjust torque, detect misalignment, or stop operation when detecting abnormal vibration — minimizing downtime and ensuring product quality.

At TASVINA, our automation philosophy is “Assist, not replace” — automation should empower engineers and operators, not eliminate them.

2. The Role of Smart Automation in Modern Manufacturing

Smart automation provides measurable benefits across all levels of manufacturing:

- Higher efficiency and productivity: Automated conveyors, jigs, and fixtures reduce cycle time and allow consistent production quality.

- Improved accuracy: Automated inspection systems and positioning fixtures minimize human error.

- Data-driven decisions: Integrated sensors and monitoring systems allow real-time performance tracking.

- Workplace safety: Dangerous or repetitive tasks can be handled by robots, reducing injury risk for workers.

- Scalability: Modular automation allows businesses to expand production without re-engineering the entire system.

Automation, when properly designed, becomes the invisible backbone that supports people — allowing engineers to focus on creativity and process improvement rather than repetitive work.

3. The “Step-by-Step” Approach – How TASVINA Implements Automation

TASVINA’s approach to automation implementation follows a phased and practical process, ensuring every investment creates real value:

- Assessment & Analysis

We start by understanding the current workflow, identifying bottlenecks, and mapping out which tasks can benefit from automation. - Customized Solution Design

Using CAD/CAE simulation tools, we design customized systems such as conveyors, robotic cells, or jigs that integrate seamlessly with existing lines. - Implementation & Testing

Our engineers build and test the system at TASVINA’s technical workshop before installing it onsite, minimizing production disruption. - Training & Support

TASVINA provides operation training and maintenance guidance to ensure smooth adoption by your in-house team.

This process reflects our core principle: technology should adapt to people, not the other way around.

4. Case Example – Incremental Automation Success

A mid-sized automotive supplier in Vietnam approached TASVINA with a challenge: their assembly line required 12 operators for repetitive positioning and tightening tasks.

Instead of proposing a fully robotic line (which would cost hundreds of thousands of dollars), TASVINA designed a semi-automated jig & conveyor system integrated with torque sensors and a simple robot-assisted module.

Results after 3 months:

- Workforce reduced from 12 → 7 operators

- Productivity increased by 35%

- Defect rate dropped from 2.8% to 0.5%

- ROI achieved within 10 months

This case proves that automation doesn’t need to be complex to be effective — when well-designed, even small steps can deliver big improvements.

5. The Human Factor – Why Engineers Still Matter

Automation isn’t about replacing humans; it’s about enhancing human potential.

Machines handle precision, speed, and consistency — but engineers provide creativity, problem-solving, and continuous improvement. The most successful factories are those where technology amplifies human expertise.

At TASVINA, we work closely with our clients’ engineering teams, helping them understand how automation systems operate, and enabling them to take ownership of their innovation journey.

6. Building the Future of Vietnamese Manufacturing

Vietnam is rapidly becoming a hub for manufacturing and engineering outsourcing. However, global competitiveness requires more than low labor costs — it demands technical innovation and efficient automation.

With over a decade of engineering experience, TASVINA provides comprehensive automation solutions for industries including:

- Automotive and components manufacturing

- Industrial machinery and tooling

- Electronics and precision assembly

- Die & Mold and jig design

By blending engineering expertise, simulation technology, and on-site implementation, TASVINA is helping businesses transform their factories — step by step — into smart, data-driven production systems.

Conclusion

Smart automation is not about eliminating jobs; it’s about elevating the role of people in manufacturing. It connects the precision of technology with the creativity of human minds, creating factories that are not only faster and safer, but also smarter and more sustainable.

At TASVINA, we’re proud to be part of that transformation — bridging people and technology to shape the future of Vietnam’s industrial growth.