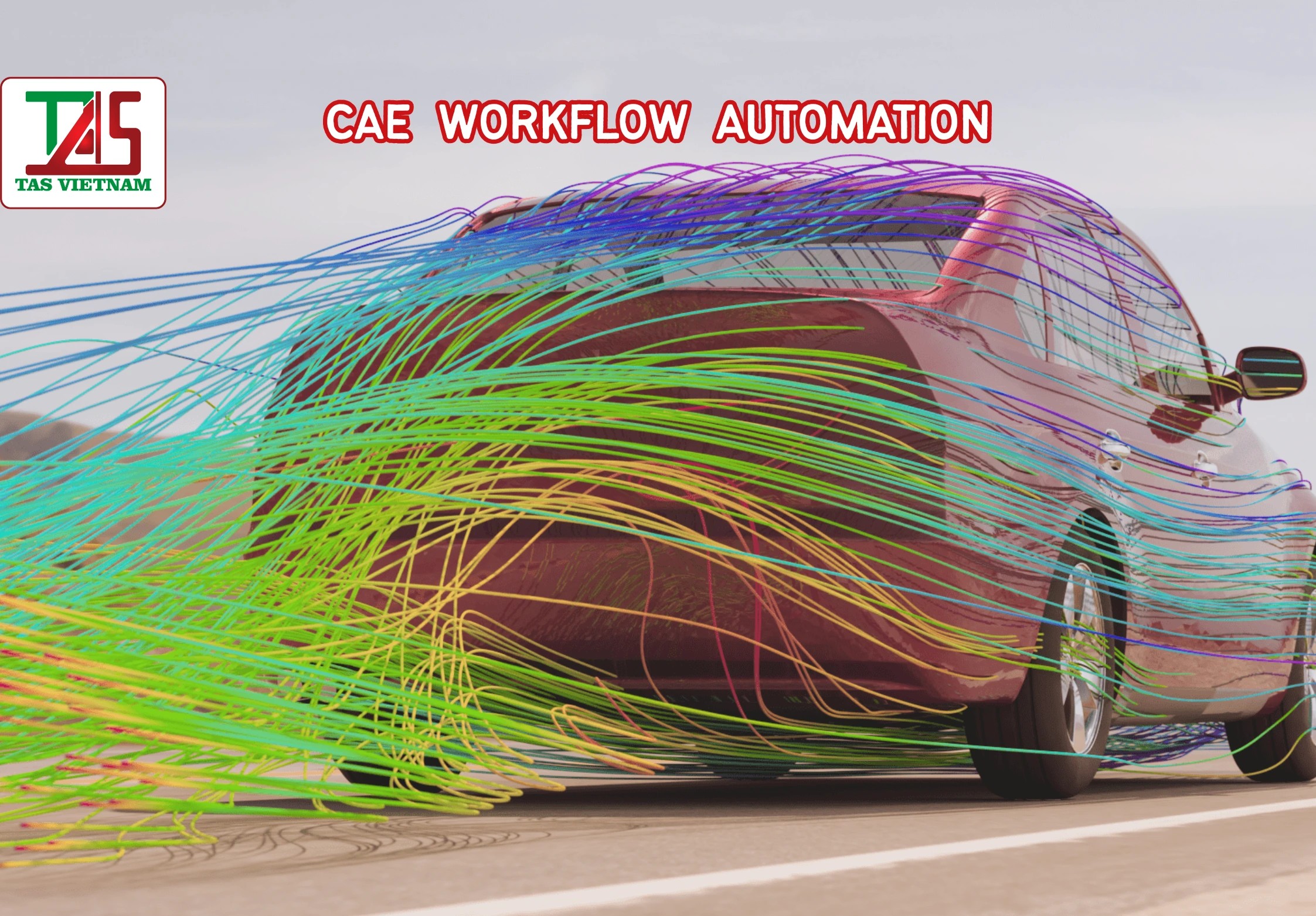

In today’s engineering landscape, the pressure to deliver innovative, high-quality products in shorter timeframes has never been greater. Global companies operating in Vietnam—especially in automotive, manufacturing, aerospace, and consumer electronics—are facing increasing demand for faster verification, higher design accuracy, and reduced development costs. Computer-Aided Engineering (CAE) plays a central role in this transformation. Yet despite its power, traditional CAE workflows are often slow, highly manual, and dependent on expert engineers performing repetitive tasks. The question many organizations now ask is: How can we evolve from failure-prone manual workflows to a streamlined, automated CAE process that accelerates development and improves product...

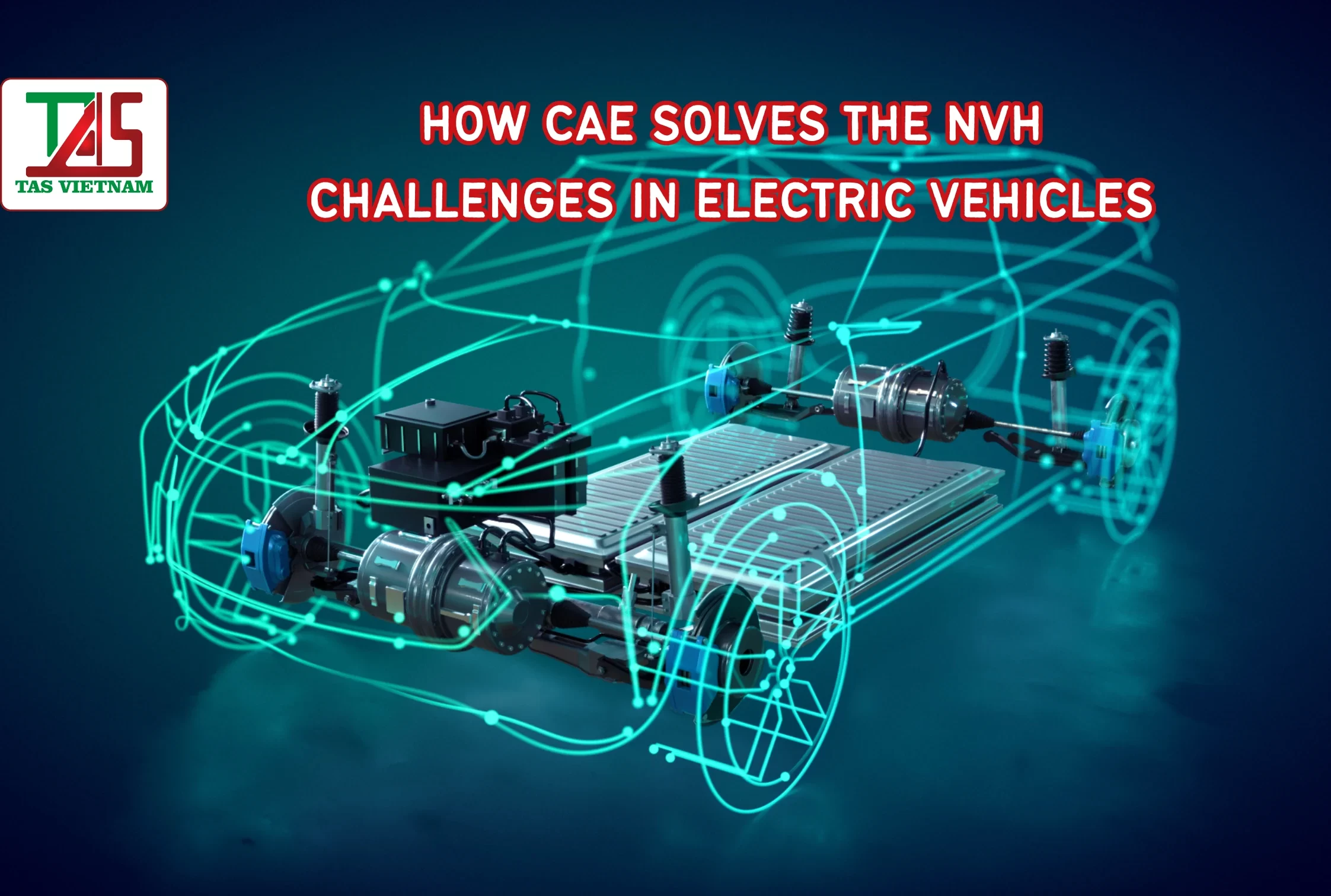

Electric vehicles (EVs) are fundamentally changing the automotive landscape, offering clean mobility, instant torque, and a quieter driving experience. Yet ironically, this “quietness” has introduced new engineering challenges. With the internal combustion engine (ICE) gone, the familiar masking noise disappears—leaving room for previously hidden noises to become more noticeable. Wind hiss, tire noise, high-frequency whines from electric motors, and structural vibrations suddenly dominate the acoustic environment. For automotive engineers and manufacturers operating in Vietnam, Japan, the U.S., and Europe, solving NVH (Noise, Vibration, Harshness) in EVs is now a top priority. And with development cycles becoming shorter, CAE (Computer-Aided Engineering)...