Description

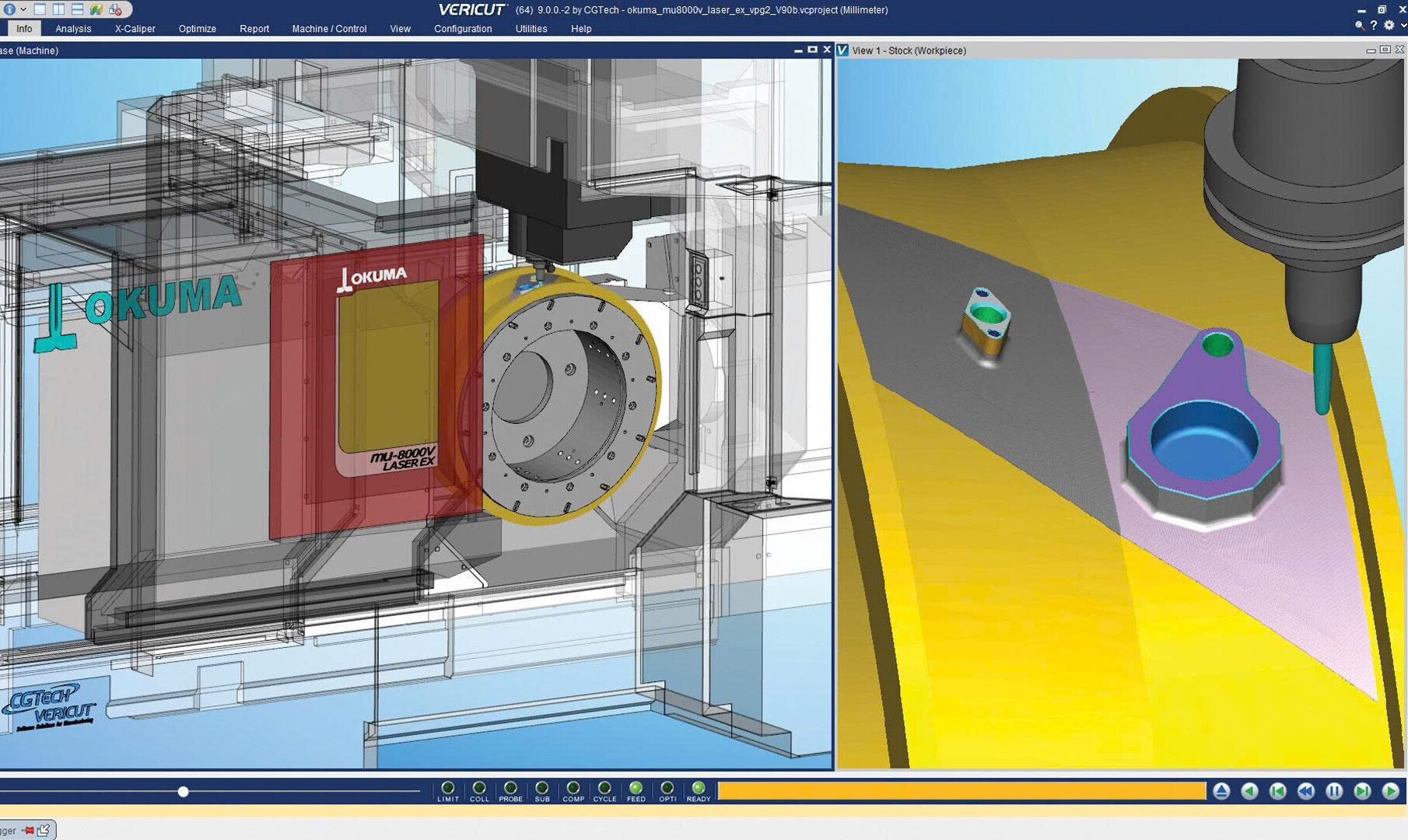

Toolpath Simulation & Optimization

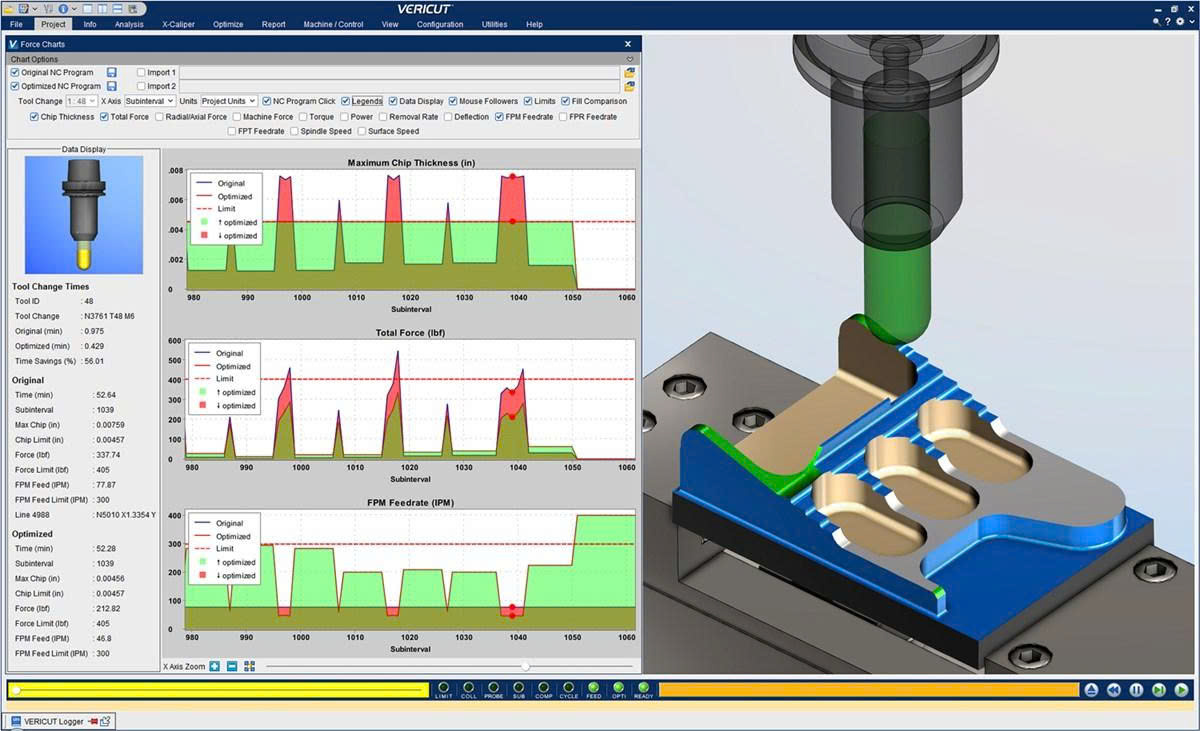

We offer advanced toolpath simulation and optimization services designed to enhance machining performance, improve surface quality, and reduce production costs.

Key Benefits:

- Toolpath Verification: Accurately simulate toolpaths to detect and prevent tool or machine collisions, protecting both equipment and workpieces.

- Cycle Time Reduction: Optimize tool movements to shorten machining time without compromising precision or quality.

- Enhanced Surface Finish: Achieve superior surface quality for components that require high precision or aesthetic appeal (e.g., molds, aerodynamic parts).

- Extended Tool Life: Implement intelligent path planning to reduce tool wear, extend cutting tool lifespan, and lower replacement costs.

- Reduced Machine Wear: Optimize operations to ensure smoother machine performance and minimize mechanical stress.

What We Deliver:

- Precise and reliable toolpath simulations

- Optimized cutting strategies tailored to your materials and application needs

Practical Applications:

- Collision Prevention: Minimize the risk of damage from tool or machine crashes.

- Cycle Time Optimization: Increase throughput and production efficiency.

- Surface Quality Control: Deliver smooth, high-quality finishes that meet functional or visual standards.

- Cutting Tool Efficiency: Improve tool performance and reduce operating costs through smarter machining strategies.

Reviews

There are no reviews yet.