Introduction

In engineering and product design, Computer-Aided Engineering (CAE) has long been the foundation for simulation, analysis, and optimization. It allows engineers to predict performance and prevent failures before manufacturing, saving both time and cost.

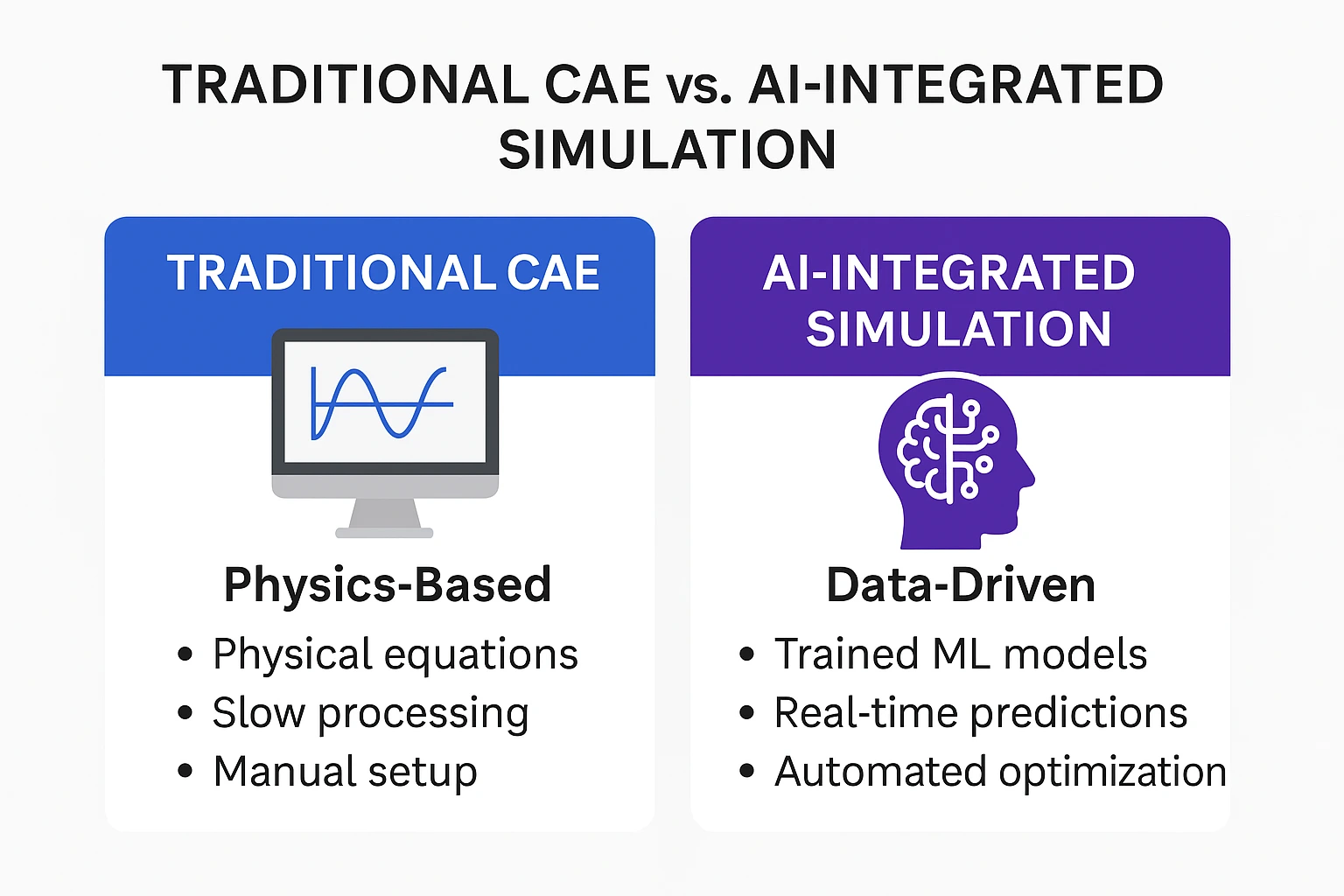

However, with the rapid growth of Artificial Intelligence (AI), a new wave of innovation is emerging — AI-integrated simulation. Instead of relying solely on mathematical models, AI-driven CAE enables learning from data, automating processes, and predicting results in real time.

This article explores how traditional CAE differs from AI-based simulation, analyzing their principles, benefits, limitations, and the future of digital engineering.

Traditional CAE – The Core of Engineering Simulation

Traditional CAE relies on physics-based solvers such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) to simulate real-world behavior. Engineers create meshes, define materials, set boundary conditions, and compute results that often take hours or days to complete.

The strength of this approach lies in accuracy and reliability. When models are set up correctly, the results can closely match physical testing. Yet, traditional CAE is computationally expensive and lacks flexibility. Each design change requires re-meshing, re-solving, and manual verification.

AI-Integrated Simulation – A Smarter Approach

AI-integrated simulation uses machine learning to learn from existing simulation data or experimental results. Once trained, AI models can predict outcomes instantly for new designs, avoiding repetitive computation.

For example, a neural network can predict stress or flow distribution based on geometry input, drastically reducing simulation time. AI also enables automated design optimization, where algorithms explore thousands of variations to identify the best-performing solution.

The Difference in Mindset

Traditional CAE depends on physical understanding; AI simulation depends on data. Engineers using CAE must define every condition precisely, while AI systems can infer patterns once they’ve seen enough examples.

This shift changes how engineering teams work — from solving equations to training models that solve equations for them. It allows real-time simulation, design iteration at scale, and intelligent insights beyond human intuition.

Benefits of AI in CAE

Integrating AI into simulation delivers multiple advantages:

- Speed – Drastically reduces computation time from hours to seconds.

- Cost Efficiency – Minimizes hardware and human effort once trained.

- Automation – AI can suggest design improvements automatically.

- Insight – Enables data-driven decisions and better visualization.

In essence, AI transforms CAE from a manual analysis process into an intelligent, adaptive system.

Challenges Ahead

AI-driven simulation still requires large, accurate datasets and careful validation. The quality of predictions depends entirely on the data used for training. Moreover, rare or extreme cases remain difficult to simulate purely with AI.

The future will therefore rely on hybrid models, combining physics-based solvers with AI to achieve the best of both worlds — precision and speed.

The Future of Digital Engineering

The next generation of CAE will be AI-augmented, where digital twins learn continuously from both simulation and real-world data. Companies like TASVINA are investing in this direction, helping global manufacturers accelerate design innovation and bring smarter products to market faster.

Conclusion

Traditional CAE ensures physical accuracy; AI-integrated simulation brings intelligence and speed. Together, they redefine how engineering is done — from reactive analysis to proactive, data-driven innovation.

The integration of AI into CAE is not the end of traditional simulation, but the evolution of it — an evolution that companies like TASVINA are helping lead, shaping the future of digital product development.