Description

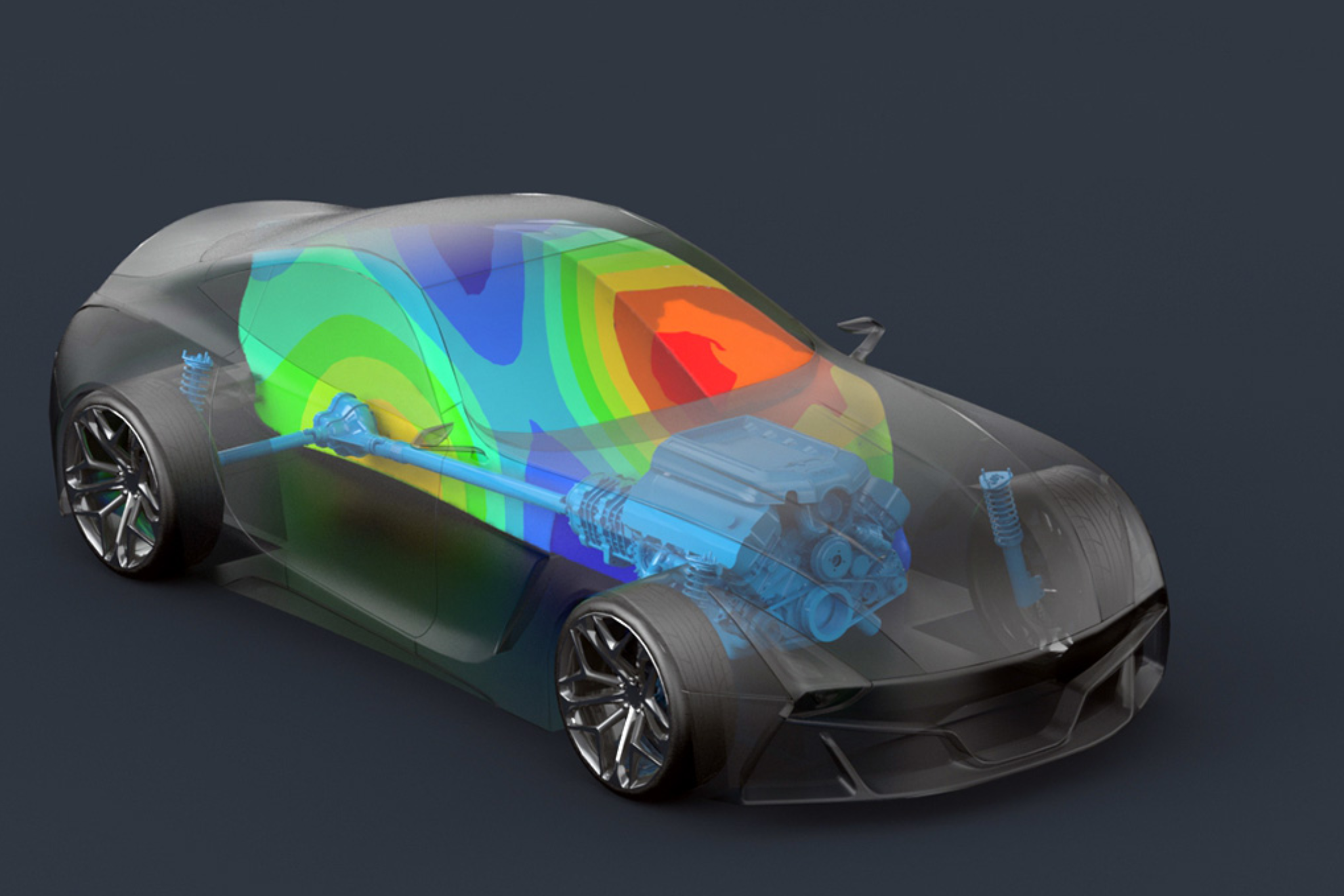

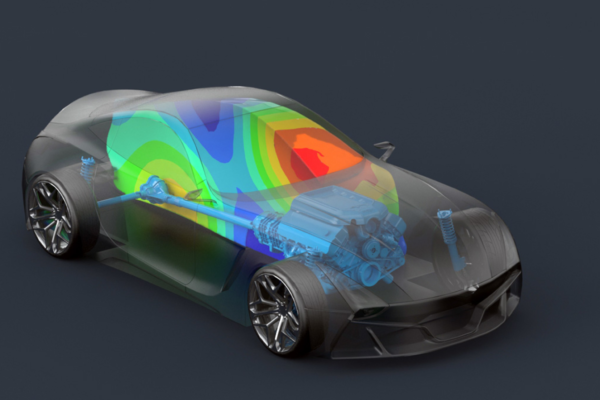

What is NVH Analysis?

NVH stands for Noise, Vibration, and Harshness, a crucial engineering field in product design and development, particularly in the automotive industry. NVH analysis focuses on studying, evaluating, and improving the noise, vibration, and harshness characteristics of a product to ensure a comfortable and pleasant user experience.

Benefits of NVH Analysis:

- Enhanced User Experience: Excessive noise, vibration, and harshness can cause discomfort, fatigue, and even affect user health. NVH analysis helps minimize these negative factors, leading to a smoother and more comfortable driving experience.

- Improved Product Quality: High noise, vibration, and harshness levels can indicate design or manufacturing issues. NVH analysis helps detect and address these problems, enhancing product quality and brand reliability.

- Compliance with Standards: Many countries and organizations have regulations regarding maximum noise, vibration, and harshness levels for specific products. NVH analysis ensures that products meet these standards, preventing legal issues and boosting market competitiveness.

- Cost Savings: Identifying and addressing NVH issues early in the design process saves production and repair costs later.

NVH Analysis Process using CAE:

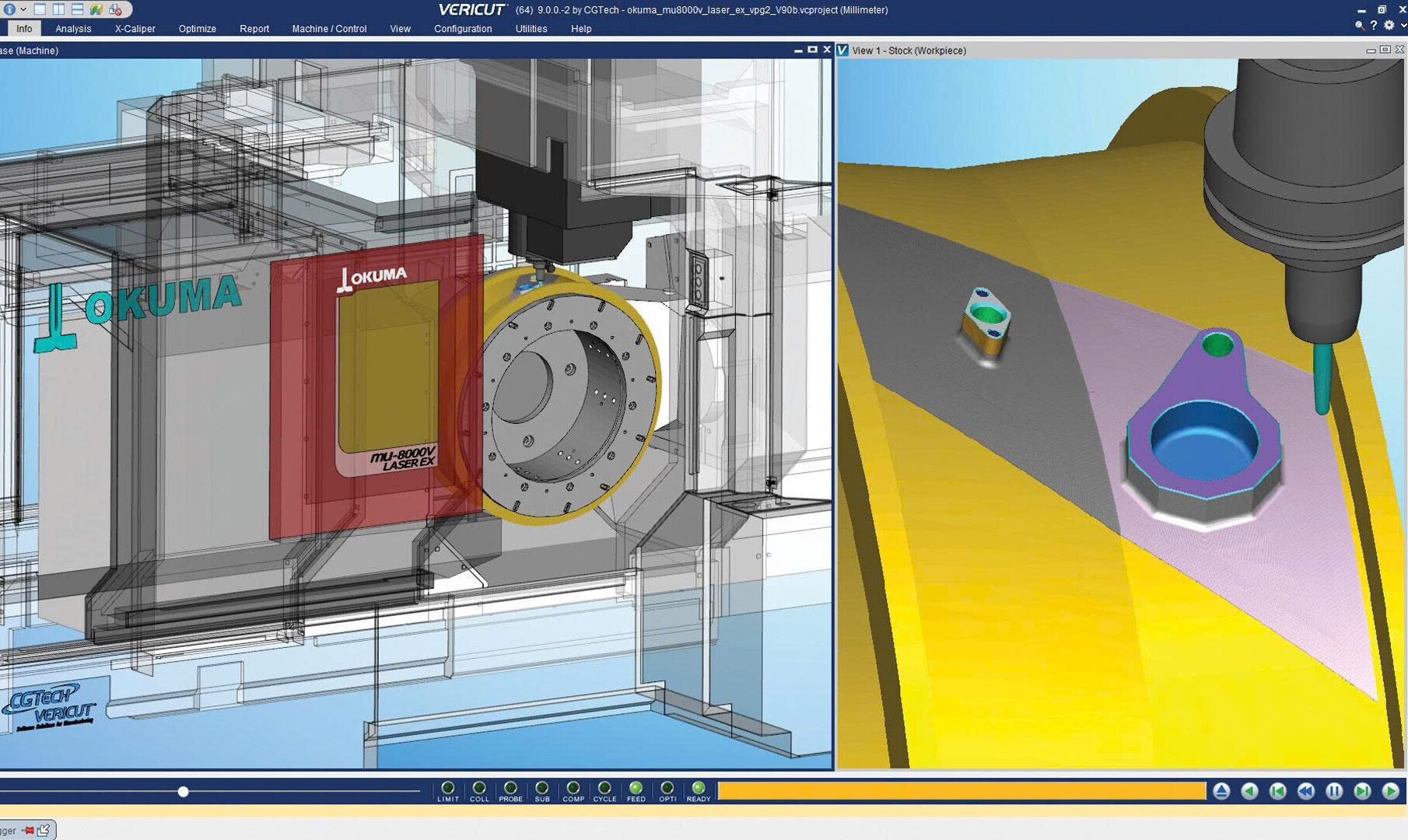

- Product Modeling: Create a detailed 3D model of the product using CAD software.

- Material and Property Definition: Provide detailed information about the materials used in the product’s components, including elastic modulus, Poisson’s ratio, and yield strength.

- Load and Boundary Condition Application: Identify the loads and boundary conditions the product will experience, such as impact forces, gravitational loads, and wind loads.

- Simulation Execution: Use CAE software to simulate the product’s behavior under the defined load and environmental conditions.

- Result Analysis: Interpret the simulation results, including deformation, stress, noise levels, vibration, and harshness.

- Iteration and Optimization: Based on the analysis results, refine the model and product design to improve NVH performance.

Role of NVH Analysis in Automotive Development:

NVH analysis plays a critical role in various stages of automotive production, including:

- Design: NVH analysis helps evaluate different design options and select the one with the best NVH performance.

- Development: NVH analysis helps detect and address NVH issues early in the product development stage.

- Testing and Validation: NVH analysis ensures that the product meets NVH requirements before market launch.

- Product Improvement: NVH analysis helps gather user feedback and refine product NVH performance in subsequent versions.

Reviews

There are no reviews yet.